Medbio LLC is a contract molder and toolmaker that designs and produces or subcontracts 100 injection molds/year that, in turn, are used in-house to mold a wide variety of medical devices and diagnostic equipment in Class 7 and Class 8 cleanrooms. Photo Credit: Medbio LLC

The FDA-registered, ISO 13485- and 9001-certified molder and moldmaker now known as Medbio LLC was founded in 2004 in Grand Rapids, Michigan. Over the last two decades, the company has grown through acquisitions and name changes. It was acquired in 2021 by plastic caps and plugs manufacturer Protective Industries Inc. that brought combined company resources to 17 facilities globally with a cumulative century of experience in contract medical device manufacturing.

Medbio produces and subcontracts production of roughly 100 injection molds per year for its molding operations to form various medical devices and diagnostic equipment in engineering thermoplastics and liquid silicone rubber. Given the diversity of parts it molds, these tools can range from single-cavity/low-volume to 8- to 32-cavity/Class 101 production. All molds are produced in tool steels, often hardened steels, owing to the need to maintain tight tolerances and provide long tool life.

Medbio also provides part feasibility reviews, 3D prints its polymer additive molding-automation components, offers tool transfer services and produces a simplified prototype/bridge tooling option. Photo Credit: Medbio LLC

The company operates 119 thermoplastic injection presses and two silicone liquid injection molding presses in ISO Class 8 or 7 certified cleanrooms at its three Michigan and one New York State molding facilities. Clamp tonnage ranges from 17 to 440 tons/15 to 36 tonnes. Among that total are a series of micromolding presses equipped with microbarrels capable of shooting parts as small as 0.08 gram/0.0028 ounce.

In addition to designing and producing molds and molding, assembling and packaging parts, Medbio also provides part feasibility reviews, 3D prints its polymer additive end-of-arm tooling (EOAT) and fixtures, offers tool transfer services and produces a simplified prototype/bridge tooling option in P20 called Prototype Plus.

Micro-Threaded Core

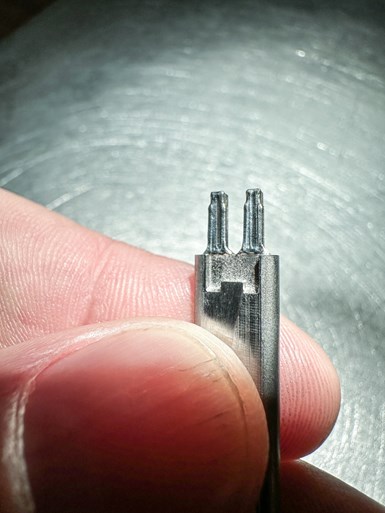

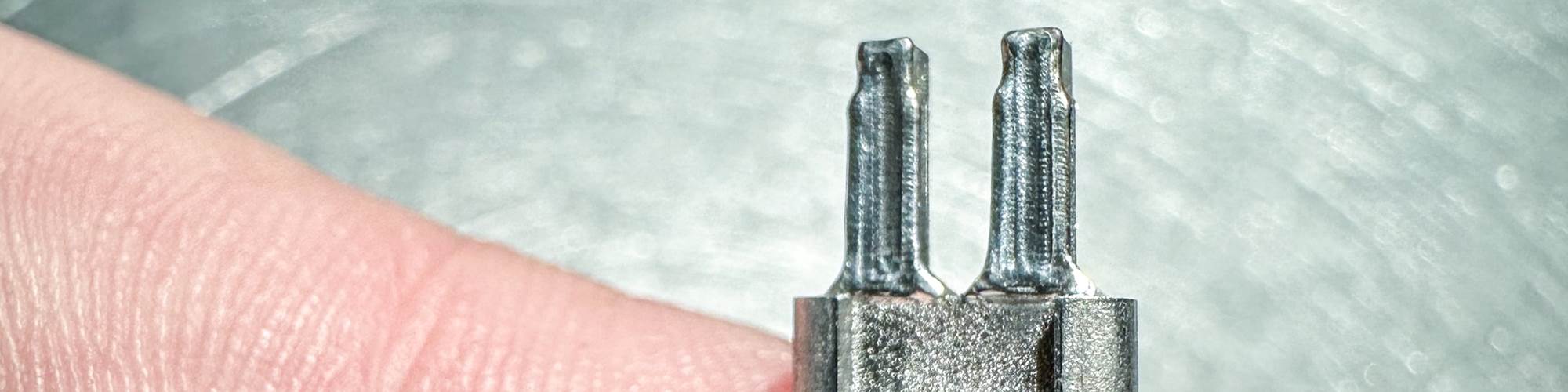

Given the types of tools Medbio designs and builds, and the parts it molds, many of its mold components are quite challenging to produce in the first place and equally challenging to repair should they become worn or damaged. Case in point, earlier this year, a two-cavity tool the team had been using since 2018 for a long-running program got damaged. To demold neat acetal parts from each cavity, the tool was equipped with specially built unscrewing cores that had to be removed by a special EOAT.

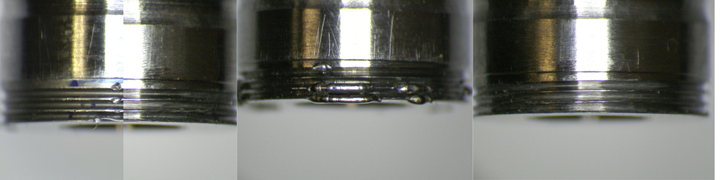

A 10-week lead time for new inserts required Medbio to send out two specially built unscrewing cores with damaged micro-threads for laser welding repair. Photo Credit: Medbio LLC

Those unscrewing cores featured polymer-coated and very thin 0.014 inch/0.36-millimeter micro-threads. The H13 mold (hardened to 52 HRC) already had 300,000 cycles on it and had been giving the molding team periodic challenges with parts sticking onto the micro-threaded cores. The parts were designed with “ears” that the EOAT grabbed to help unscrew the part from the insert. Unfortunately, the ears would sometimes break prematurely, making removing the part from the insert impossible for the EOAT. In that situation, technicians manually demolded parts — often using brass pliers — which, over time, damaged the polymer coating, led to more part sticking and eventually resulted in damaged micro-threads. Although Medbio had originally commissioned two spares for each core, all spares had been damaged and none were usable.

Above are the two side-by-side inserts showing damaged threads (left); one insert during laser welding repair work (middle) and the same insert after repairs and polishing were complete (right). Photo Credit: Alliance Specialties and Laser Sales

This situation created a serious challenge, as building new unscrewing cores would take 10 weeks and customer stocks of the critical medical parts weren’t high. While Medbio’s mold services team does make many repairs in-house, and the company already owned a laser welding system, the intricacy of the threads and the challenges of making repairs, blending the repairs back into the rest of the metal and polishing them was deemed beyond their capabilities. The team also felt that the threads were of such fine resolution that the cores would be too difficult to print via metal additive manufacturing.

While the team had already been developing a new mold for this program, it wasn’t ready and would still need to undergo a rigorous customer validation program before it could be put into production. Given this extremely challenging repair, the team sent both damaged cores to Alliance Specialties and Laser Sales to get the mold back in operation as quickly as possible.

Sculptors in Steel

Founded in 1978 by a moldmaker turned mold polisher, and eventually a mold services provider, the Alliance family of companies offers many highly useful services to the tool and die industry from four locations in Wauconda and Prairie Grove, Illinois and Montclair, California. Alliance Laser Sales Inc. produces and sells its line of American-made laser welding and engraving equipment and specializes in laser welding and engraving services for both high-volume production needs and plastic injection mold repair and finishing. Alliance Specialties Corp. provides the tool and die industry with mold finishing and polishing, mold repairs, preventative maintenance, refurbishment and hot runner cleaning. Typical welding work includes restoring cut edges, repairing shutoffs, making engineering changes, fixing water leaks, repairing broken cutters, fixing cutter gouges, making engraving changes and repairing voids caused by EDM arcing.

Just on laser welding repairs alone, Tony Demakis, Alliance president, says that the company has completed more than 60,000 jobs in the tool and die industry in the last 20 years. The Alliance team was an early adopter of laser welding when the technology came to market two decades ago.

“When we first tried it, we realized this was great technology that could revolutionize the industry and make repairs faster and easier,” Demakis says. “We knew this was something that other companies would start to offer, so we brought the service inside, bought our first machine from Germany and then partnered with that company to rep their products while also offering laser welding services.”

Eventually, after bringing suggestions to the machinery OEM multiple times on how to improve the equipment to better serve customers and being rebuffed, the relationship was severed and Alliance began designing and building its own laser welding equipment and repping other brands. In the intervening years, laser welding has undergone many technical advances, some developed by Alliance, and the team has built deep experience in the intricacies of laser welding.

What are the benefits of laser welding versus tungsten inert gas (TIG) welding? Laser welding is extremely fast and doesn’t require the substrate to be preheated and later cooled. It causes very low heating, minimizing workpiece distortion, permits very thin materials to be welded in close proximity to thermally sensitive materials, and enables joining of materials with different coefficients of thermal expansion (CTEs) and materials that normally can’t be welded. Laser welding is unmatched in accuracy and can produce extremely fine welds (0.1-1.0 millimeter/0.004-0.040 inch and at times as small as 50 microns) using wires as thin as 0.0762 millimeter/0.003 inch. Since it involves minimal deposition of welding materials, little to no post-weld machining is required, and since no electrode is used, there is no risk of introducing contaminants to the metal structure. In addition, there is no turbulence to destroy the protective inert gas atmosphere, there is no concern about arcing, since the beam moves in a linear path only and is unaffected by magnetic fields, and it facilitates welding in difficult areas like tight and deep geometry.

“If something is in our facility, it’s bad for our customer and our customer’s customer because everyone is losing money, so we get things turned around as quickly and efficiently as possible.”

Close Communications

While Medbio has only been using Alliance’s services for 15 months, Alliance has become Medbio’s go-to source for laser welding and other mold repairs. “We even purchased an ID1-Fiber laser welder from Alliance, which is so easy to use that even engineers can be trained to operate it,” chuckles Micah Barbera, Medbio toolroom supervisor.

Laser welding offers a host of benefits for tool and die repairs over TIG welding. Photo Credit: Alliance Specialties and Laser Sales.

How difficult were the Medbio micro-threads to repair? “Given the projects people send us, our work is largely triage and repairing the unrepairable, so nothing is that challenging anymore,” notes Rick Hendry, Alliance laser welding foreman, who completed this Medbio repair. “This project used finer wire — five-thousandths — and the thread size, thinness and intricacies, plus the precision we had to achieve, made it challenging, but this is what we do every day. You have to know your settings and how to dial it in, plus not get frustrated and give up.” Hendry repaired both core inserts and returned them to Medbio within a week.

“If something is in our facility, it’s bad for our customer and our customer’s customer because everyone is losing money, so we get things turned around as quickly and efficiently as possible,” explains Mike Zender, Alliance mold maintenance manager, who describes his welding team as little sculptors in steel. “We’re an extension of our customer’s toolroom. We have to live inside the guidelines they set and recreate something that already exists while meeting our customer’s needs.”

“Given the complexity and timing of this job, Alliance is the only shop we felt super confident could do it and do it right,” explains Steve Trierweiler, Medbio senior project engineer. “They have six laser welders on staff and a neat business model. They don’t build molds but are here to help support mold builders and molders on the service side.”

“The core inserts were ready to install when we received them, although we did have to go through customer qualification tests again,” recalls Tim Smith, Medbio senior tooling engineer. “We passed and were back to molding that same week, which is good as our customer was almost out of parts.”

Smith adds that Medbio was so impressed with Alliance’s work on the unscrewing cores that they’ve already sent several other challenging projects to Alliance and have been equally pleased with the results.

Related Content

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreHow to Achieve the Best Mold Finish

A look at factors that impact the polishability of tool steels and recommendations for obtaining a high-gloss finish.

Read MoreLine Width vs. Depth Ratio in Laser Engraving

A laser does not produce 90-degree sidewalls. It requires a certain amount of draft in order to produce the required pattern.

Read MoreWhat is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreRead Next

VIDEO: Can You Integrate a Joystick onto a Robot for Mold Repair?

Tony Demakis, President of Alliance Specialties and Laser Sales and Brian Conner, Channel Development Manager at Universal Robots answer the question of whether or not you can integrate a joystick onto a robot for mold repair.

Read MoreQuestions and Considerations Before Sending Your Mold Out for Service

Communication is essential for proper polishing, hot runner manifold cleaning, mold repair, laser engraving and laser welding services.

Read MoreTime to Take Welding in a Different Direction

With an in-house laser welding system, this mold builder increased its sales numbers by turning mold repair work around faster.

Read More

.jpg;width=70;height=70;mode=crop)