Internally Heated Hot Runner Nozzles: Leak-Free Performance for More Profitable Production

Case Study, Hot Runners, Packaging

As any mold builder knows, the hot runner system is usually the most costly part of the mold. Successful operation of a hot runner system depends on several factors, not the least of which includes excellent design, proper system assembly and comprehensive training of those who will live with the mold.

Anything less than this can open one up to a very serious issue called hot runner leakage. A leak can be very difficult to detect and often, once it is found, can be catastrophic. Those who have experienced hot runner leakage know all too well the hours and expense involved in getting the system and mold back into production.

So it makes sense to say that when you have a product that does everything it promises and more, you stick with it. At least that’s the thinking of one Melt Design, Inc. customer who is the plant manager at a major OEM producer of injection molded closures for the food and beverage packaging industry.

“I actually discovered Melt Design’s internally heated hot runner nozzles more than 20 years ago,” he explains. “I was working at another OEM located in the Chicago area at the time. We were getting away from split plate hot runner technology and more into the enclosed systems because they are more reliable with less leakage. In fact, I can’t remember the last time I had a leak failure.”

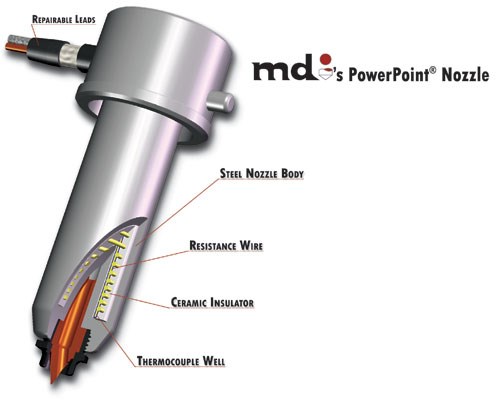

Based in St. Charles, IL, Melt Design specializes in the manufacture of runnerless injection molding systems. Its internally heated hot runner nozzle, the patented PowerPoint® Nozzle, features finite temperature control. They resist burning out and are 100 percent sealed, so plastic material cannot leak out and damage wires in the channels or nearby nozzles.

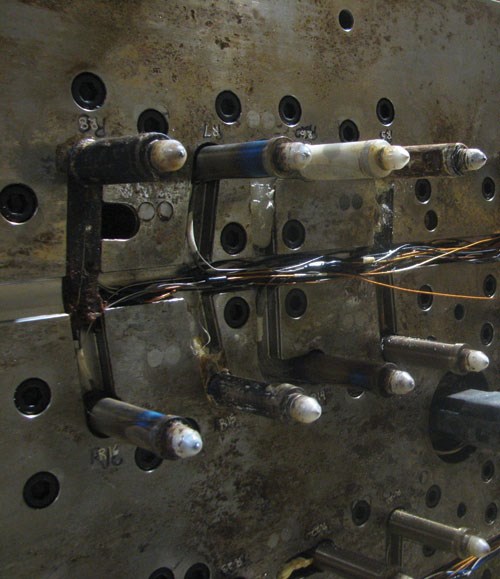

With traditional externally heated nozzles, leaking and system damage can and does occur. Worse, if one externally heated nozzle leaks in a hot runner system more often than not the leaked plastic will follow the wire channels and flood them, causing all of the nozzles and channels to become one big, expensive plastic mess. It can be even more expensive to repair if the entire heating system is affected.

“I’ve never had a mold damaged by plastic leakage while using Melt Design’s systems,” the plant manager adds. “When I left Chicago to take my current position I found that too often our operations were burdened by poor performance by other brands of hot runner systems. I knew the internally heated nozzles from Melt Design were higher quality and more reliable, so we switched.”

Since that time the OEM’s operations have benefitted in the following ways:

• Productivity has increased 15 percent due to reliability

• Reduced material waste

• Reduced downtime

• Easier to clean system

• Easy to disassemble while mold is still in the molding machine

Currently, he said, there are as many as 30 molds in production, featuring anywhere from four to 64 cavities. Each employs the internally heated hot runner nozzles.

“These molds produce millions and millions of shots with very tight tolerances. Occasionally you do need to do some cleaning, but these systems are so easy to disassemble to clear a gate,” he notes. “I’d be comfortable saying that I have no downtime caused by the internally heated hot runner nozzles. The tech support is always excellent from initial development of new tooling through to production and the systems are very cost competitive.”

Internally heated hot runner nozzles provide money-saving, leak-free performance. It’s one significant benefit that makes these nozzles worth investigating.

Related Content

What is Driving Mold Lifecycle Management Digitalization?

OEMs are looking to partner with suppliers to share and track data across the supply chain for advanced intervention and process management.

Read MoreMMT Chats: Digitalizing Mold Lifecycle and Process Performance

MMT catches up with Editorial Advisory Board member Bob VanCoillie senior manager of Kenvue’s mold management center of excellence outside of Philadelphia to discuss mold management via tooling digitalization and OEM expectations and opportunities.

Read MoreR&D Drives Innovation and Problem-Solving at Michigan Blow Mold Builder

Mid-America Machining focuses on reshaping designs, “right weight" initiatives, continuous improvement and process refinement to enhance moldmaking efficiency.

Read MoreCompact Robotic Palletizer Easily Automates Packaging Process

The Cube cell, complete with a KUKA KR50-R2500 robot, is targeted for small- and medium-sized businesses looking to automate the palletization of their end product.

Read MoreRead Next

Savings from the Front Lines: Using Hot Sprue Speeds Cycle Times, Yields Cost Savings

This quarterly series features actual examples of the front-line mold building company presenting new approaches to improve the customer’s profitability.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More