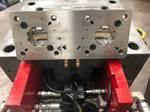

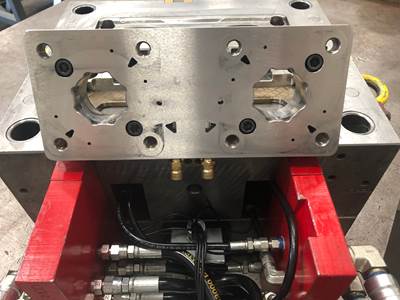

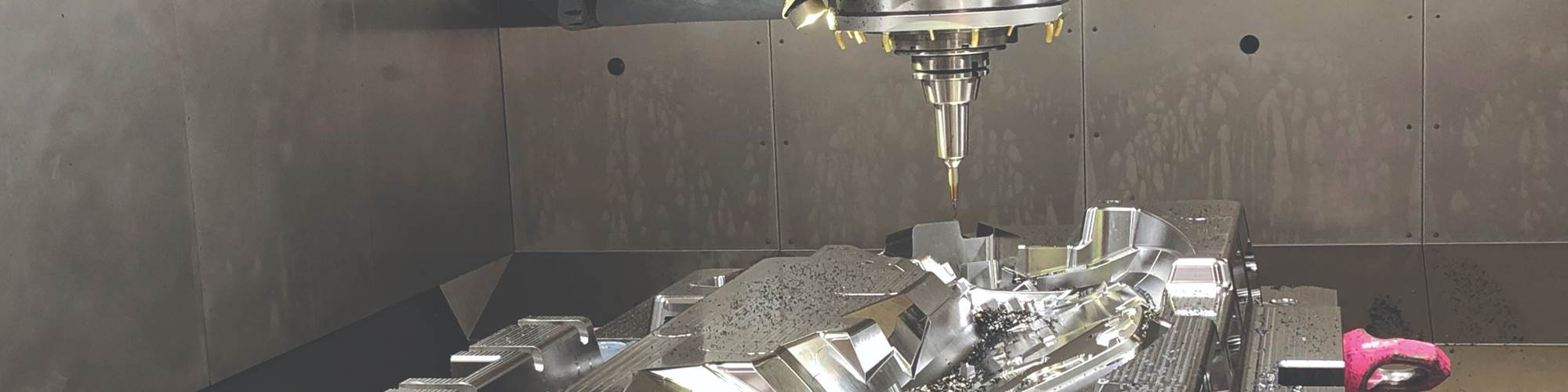

The majority of mold components Hi-Tech Mold & Engineering prints are in MS1 alloy (maraging steel), which has properties similar to P20, making post-print machining, EDM, grinding and welding much simpler. By focusing on one material, the moldmaker avoids costly and time-consuming changeovers that are otherwise necessary to prevent cross-contamination between metals. Another Hi-Tech innovation is that it machines a P20 base, which functions as a scaffold on which the MS1 component is printed, including channels and conformal cooling lines. This hybrid design significantly reduces overall printing time and eliminates the need to cut the printed item from its build plate. All Photo Credit: Hi-Tech Mold & Engineering Inc.

Founded in 1982, Hi-Tech Mold & Engineering Inc. is a full-service moldmaker employing 240 associates and headquartered in Rochester Hills, Michigan. The company offers R&D, mold design/engineering/production, program management, custom machining/EDM, benching and polishing, additive manufacturing/3D printing, a CMM laboratory, tryouts and mold validation and service/repair with 24-hour turnaround. At its Michigan location, the company also offers low-volume injection molding and assembly. At two

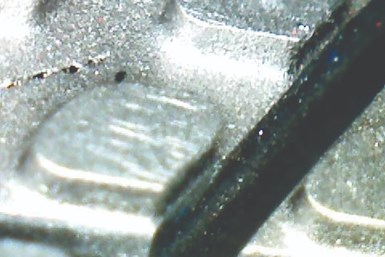

3D printed mold inserts (like the first image and this detail from that insert) not only enable fine features to be molded, but also provides vital venting to evacuate gases to prevent dieseling, voids and die-lock.

other locations—in Winchester, Tennessee, and Westminster, South Carolina—the company offers mold design/build/repair under the Hi-Tech name, while sister company Baxter Enterprises provides production injection molding and assembly for the plastics industry. To support global programs, Hi-Tech is also a landing house for offshore molds being prepared for use in North America and produced by partners in Asia, Europe and South America. Hi-Tech and Baxter are major suppliers of tooling and parts to the automotive industry, but also service other ground transportation segments along with medical, appliance and defense. Hi-Tech also provides custom aerospace machining.

Extending Traditional Technologies

“Over the last couple of decades, our company has continued to evolve by adopting many of the developing technologies of Industry 4.0,” Paul Glowicki, Hi-Tech chief operating officer remarks. “With our use of data analytics, machine learning, adaptive scheduling, simulation and additive manufacturing, we look for competitive advantages to remain a leader in moldmaking and machining.”

The company began using local suppliers to produce 3D-printed metal mold components in 2013. After thoroughly researching available technologies, in 2014 Hi-Tech acquired its first metal 3D printer from EOS North America (Novi, Michigan)—an EOS M-290 model—and in 2016 purchased a second of that same model. Both printers use direct metal laser sintering technology (DMLS, which EOS has rebranded as direct metal laser solidification “to more accurately reflect the nature of the process”).

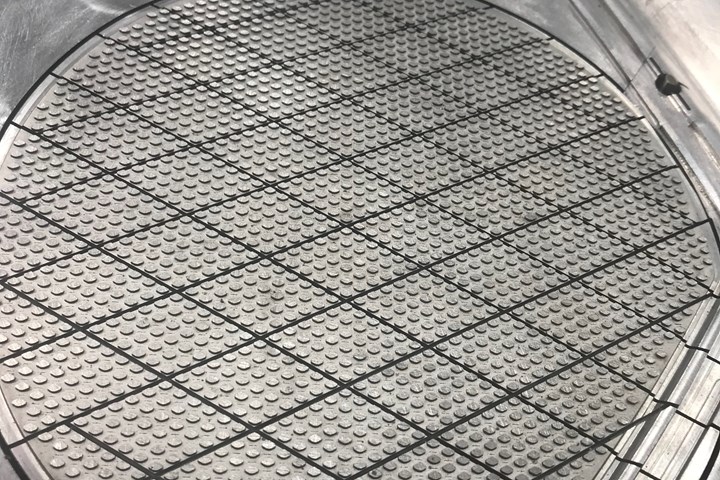

“We went with DMLS printers because that technology offered the right choice for our main use-case, which was mold inserts,” Mark Krauzowicz, Hi-Tech additive manufacturing specialist explains. “Insert vents have to be large enough to evacuate gas quickly, but small enough to prevent clogging by plastic melt and mineral fillers. With DMLS, we can produce parts—in the alloy of our choice—that are 99.9% dense. In contrast, printing technologies like metal binder jetting incorporate a binding agent in the metal powder that has to be flashed off in a post-print heating process, which adds time, cost, energy and the risk of shrinkage and warpage, making it hard to control vent size. DMLS gives us more predictable out-of-printer components; the tradeoff is a slower printing process and disposal costs associated with removing metal-condensate by-products.”

Hi-Tech Mold & Engineering, Inc. is a full-service moldmaker with operations in Michigan, Tennessee and South Carolina. Along with its sister company Baxter Enterprises, Hi-Tech is a major supplier of both tools and parts for the global automotive industry, including interior Class A, molded-in-color parts and exterior Class A hard trim and underbody components. Additionally, the company serves customers in other ground transportation segments (commercial truck, agricultural equipment, recreational/all-terrain vehicles) as well as medical, appliance and defense, plus provides custom machining for the aerospace segment.

Machined vs. 3D-Printed Inserts

A few years ago, Hi-Tech was awarded a large tooling contract by an automaker and its tier integrator. The job entailed producing more than 60 production injection tools to mold interior door-trim panel uppers, lowers, map pockets and bolsters for many pickups and sport-utility vehicle models. Program life was anticipated to be seven years plus service, and total vehicle build with all models of the vehicles was estimated at 300,000 annually. As part of the job, 28 of the tools included speaker grilles, which would require 8-inch x 6-inch/20-centimeter x 15-centimeter inserts to produce the fine holes.

Hi-Tech produces prototype and production molds for most plastic processes, particularly injection (including gas-assist, 2K/overmolding, core-back, stack and low-pressure molding), as well as compression, and injection/compression. While the toolmaker can produce molds in the full range of sizes (from 100 to 4,000 tons/tonnes), its specialty is large molds that typically fit presses ≥750 tons/tonnes. Most are complex tools requiring side action.

“Given the size of the holes we were dealing with, we knew from the start that we’d need good venting throughout the geometry to fill those parts without defects,” recalls Glenn Jacks, Hi-Tech engineering director. “Typically, we’d use a porous steel insert for this kind of application. Although our customer had limited experience with that type of material, they knew it required a high level of care to maintain good venting performance. A further complication was that we’d recently heard the supplier of a popular brand of porous steel was ceasing production, making the material more difficult to obtain.” These factors caused Hi-Tech’s customer to worry about high maintenance costs and production interruptions on tools being shipped to plants in the U.S. and Mexico. They challenged the moldmaker to find another solution, which, fortunately, Hi-Tech already had.

“We went with DMLS printers because that technology offered the right choice for our main use-case, which was mold inserts.”

Sintered porous metal-matrix composite (MMC) has long been used in injection molds to improve venting, gloss levels, cycle time and pressure and scrap/reject rates. However, its tiny pores (~7μm) on every surface (including shutoffs), weren’t connected, so gases had to take convoluted paths to escape during venting. Under fast-fill conditions, this could lead to voids, dieseling and die-lock as plastic became trapped in pores along sidewalls. Another problem reported by Hi-Tech’s customers was that after ~50,000 molding cycles, inserts had to be removed and cleaned.

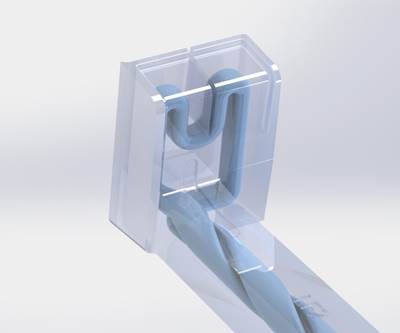

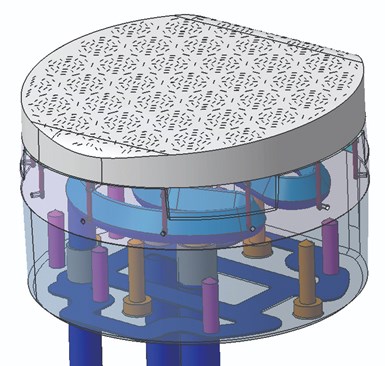

Among the many advantages of additive manufacturing is that vents can be engineered only in surfaces that require venting—like rib bottoms—but not sidewalls or shutoff surfaces. Printed vents can be designed as continuous channels sized to vent gas quickly while restricting plastic flash-through, and spaced and shaped to follow part geometry. Additionally, conformal cooling lines can be incorporated, so moldmakers and molders needn’t choose between addressing gas traps or hot spots.

“Porous steel is a valid solution for solving quality issues on injection molded parts, but it’s also given moldmakers and molders a lot of headaches,” Jacks adds. “In addition to the high cost of raw blocks and the fact that there is a limited supply base, it requires delicate handling to produce a finished insert.” During machining and polishing, the material being removed can easily be folded back into pores, blocking them, as can the oils and sprays mold shops and molders use daily, he notes. Another issue is that cooling lines can’t be drilled into porous steel without going back and plating the holes, forcing moldmakers and molders to balance the tradeoff between gas traps and hots spots. “Although porous steel provided good breathability for venting gases, the inserts have both durability limitations and maintenance concerns for molders,” Jacks continues. “When pores get clogged, maintenance is slow, arduous and costly. Inserts must be removed from tools, sent to outside vendors and cycled through ultrasonic baths for at least 12 hours. That’s why we always produced backup inserts to keep tools in production.” In the case of this program, that meant 2 inserts/cavity x 28 molds.

Since they’d been using MMC for inserts for some time, Hi-Tech was already aware of the benefits and challenges with these materials. “A few years before we got this job, we’d gone in search of a better answer for venting problems and that’s how we got started with 3D printing,” explains Anthony Debenedictis, Hi-Tech senior designer. “Not only were we able to print conformal cooling lines into our metal inserts but—thanks to metal’s superior thermal transfer—we directly tied our water circuits to the water manifold for the rest of the mold. That enabled us to eliminate press-side temperature-control units, which are usually needed with MMC inserts to assist plastic flow through the grille geometry.” Hi-Tech had produced at least 10 3D-printed speaker inserts with engineered venting before being awarded this program and one of the tools had been in operation for over a year, proving the concept worked.

Unlike MMC inserts, pores in metal additive inserts don’t require special cleaning and rarely clog. The only maintenance needed is a daily flush with shop air through an externally-mounted port to keep the channels free of debris. In 2017, Hi-Tech’s engineered vent strategy was awarded a U.S. patent for design and use of a 3D printed insert to form speaker-grille details.

Given concerns about potentially high-maintenance costs with porous steel inserts, and customer willingness to consider new technology, the program planned two inserts for each cavity: one in MMC (the primary) and one in printed maraging steel (MS1 alloy; the backup).

“The program’s lead tool headed to initial tryout with printed inserts in place so all parties could assess their performance,” recalls Jacks. “The results were so overwhelmingly positive that specs for the remaining tools were changed, designating the printed insert as the primary and MMC as the backup. Since that program, we’ve had many other programs launch with exclusive use of 3D printed inserts for both primary and backup. In fact, to date, we’ve used metal additive inserts in over 70 molds, with more in planning and production, and in 2017 we were issued a U.S. patent for our work in this area.”

Gaining Ground with Moldmakers

EOS GmbH was founded in Krailling, Germany, in 1989 and supports customers globally. Although the company initially focused on supplying plastic printers and materials, it added metal printers and materials in 1995.

Hi-Tech was an early adopter of metal additive manufacturing for moldmaking. Starting in 2013, the company began using a local print service to produce metal mold components. By 2014, Hi-Tech had acquired its first metal printer—a DMLS system from EOS North America (model M-290)—and it acquired a second of these EOS models in 2016. These machines feature a 10-inch-cubed/25-centimeter-cubed build area and can print a broad range of metals, although Hi-Tech primarily focuses on MS1 alloy (maraging steel). While the moldmaker primarily purchased the printers to produce mold inserts, over the years it has expanded its use to even include printing replacement gears for older milling machines.

“Today’s 3D-printed metal parts are fully dense and incredibly robust, which is why they can be used in aircraft, medical devices, plastic molds, casting dies and many other mission-critical applications,” explains Jon Walker, EOS North America business development manager, who notes that traditional moldmaking won’t go away anytime soon, but greater trust is building within the industry as more decision-makers experience the capabilities of metal additive manufacturing—particularly how well such parts meet the rigorous demands of moldmaking and high-pressure die casting. “Hi-Tech has a strong understanding of the value and benefits of metal additive and they really did their homework before buying their first printer,” Walker adds. “It’s been a very good partnership.”

“EOS has been an important partner to us—especially on this tooling program,” recalls Krauzowicz. “They helped us overcome many challenges, including printing speed, laser intensity and geometric design. Cooling simulation was also critical to help us determine how to intertwine venting and cooling channels to make the greatest impact on molded parts. It truly took a team effort to achieve working components in an efficient manner.”

Walker notes that plastic parts produced from tools with 3D-printed components generally have higher dimensional accuracy. “There are lots of underutilized applications and huge opportunities to leverage 3D printing in moldmaking—especially for snap-fit parts,” he adds.

“One thing to remember,” notes Jacks. “Metal additive is not much faster than traditional methods of machining a porous steel insert. It takes about 100 hours to print a 6-inch (15-centimeter) piece, and that’s after spending several days in CAE developing the vent architecture. Our two printers were working continuously for weeks to complete all the inserts we needed across all the tools in this program.”

Interestingly, not only has Hi-Tech used its printers to create mold components, but they’ve also printed replacement gears for their milling machines. “Additive manufacturing is a significant investment for any company, as aside from the machine purchase, there’s the need for a clean room and to support significant employee training,” Glowicki continues. “Because of that, it takes time to realize ROI. However, as rapidly as the technology is advancing, with larger printing envelopes and faster machines, its limitations for moldmaking are bounded mainly by user imagination.”

About the Author

Peggy Malnati

Peggy Malnati is a Detroit-based contributing writer for MoldMaking Technology focused on case study/application stories and shop profiles. She has also been a contributing writer for CompositesWorld since 2006, for which she primarily covers automotive and ground transportation.

A long-time member of SAE and SPE, she has organized and managed large technical sessions and conferences for both organizations as well as for the former Structural Plastics division of SPI. For 15 years, she was a board member and the communications chair for the SPE Automotive Division. She also was editor of the 1994 McGraw-Hill book Structural Analysis of Thermoplastic Components. She has provided writing and communications services for the global plastics and composites industries since 1984.

Related Content

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read More6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreRevisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

Read MoreRead Next

Additive Tooling Goes Beyond Conformally Cooled Inserts to Simplify the Mold Build Process

Three ways that additive tooling is moving past conformal cooling to bring speed and efficiency to the overall tooling process.

Read MoreHow to Design a Mold with Additive Tooling

Designing molds with additive tooling implementation in mind requires blending traditional mold standards with innovative new ideas of what is possible to push the limits of mold performance.

Read MoreSelling the Value of Additive Tooling in a Mold

Gaining molder buy-in for a conformal-cooled mold insert requires communicating the mold’s total cost of ownership over the life of the project.

Read More

.jpg;width=70;height=70;mode=crop)