Design impacts how a customer perceives a car and laser texturing influences that design. The process offers limitless design possibilities, eliminates manual work, digitalizes processes, cuts development and delivery times and creates a comprehensive end-user experience.

“We dress the naked part,” is how Marco Reichle describes what Reichle Technologiezentrum does. Located in the Kirchheim unter Teck near Stuttgart, Germany, this one-stop service provider for tool and moldmakers specializes in laser welding, mold repair, engraving, and polishing. The company also offers laser texturing, in-mold coating and design development.

Since investing in the first laser ablation machine from GF AgieCharmilles in 2012, the 29-year-old entrepreneur, who runs the 80-men strong company together with his father Volker and sister Marina, has invested in 13 laser machines. This investment is on top of 12 machines in its new China subsidiary. All of this new technology replaces the traditional chemical etching process they use to texturize and sandblast molds for gloss level adjustments.

“It’s important to invest in innovative concepts to meet the changing requirements of the automotive industry, where the design will be more diverse in the coming age of autonomous, electric vehicles,” Reichle says. “As design becomes less about technical specifications for such things as the engine and chassis, car manufacturers will be challenged to design a comprehensive user experience. For example, the part surface the end user will see and touch will play a key role in deciding which automobile brands survive into the future.”

A Real Alternative to Etching

Almost any design option or requirement on haptics and optics can be realized with laser texturing. Examples would include glossy, grained, dull, smooth, structured or rough-shaded textures, and simply elegant or just functional textures. The process is reliable and repeatable since manual work is eliminated and all structures are digitally created and reproduced on the laser.

“Gone are the days when you had to rely on laborious and error-prone manual work,” Reichle says. “This type of surface treatment offers a real alternative to conventional etching, blasting or erosion processes and makes surfaces possible in injection-molded parts that were previously not feasible.”

“We can set the gloss level variably within the grain, and it will stay constant over the entire production cycle, largely without wear,” Reichle says. “Amorphous plastics such as PC-ABS, ASA, POM, etc. shine much stronger than, for example, PP. However, according to the current trend, a high-quality impression only results from matt gloss levels in plastic parts. With special microstructures that we lay over any grain, we can continuously adjust the gloss level. This makes it child's play to achieve a low degree of gloss level (0.5-2.0 GE) even in amorphous plastics, identical to PP.”

Laser technology can also help shops realize scratch-resistant structures, which are becoming increasingly popular in the automotive industry. For example, stressed areas, such as spoilers or door sills, that are designed to be water-repellent, and where very dull surfaces are designed to reduce reflections from the dashboard to the windshield.

Reichle, who works for and with a diverse range of industries but increasingly with automotive OEMs, takes laser texturing to a high level. He says this requires a lot of dedication, experience, investment in the right equipment, experienced staff and a team of designers who design the most advanced textures for their customers.

Cutting-Edge Design

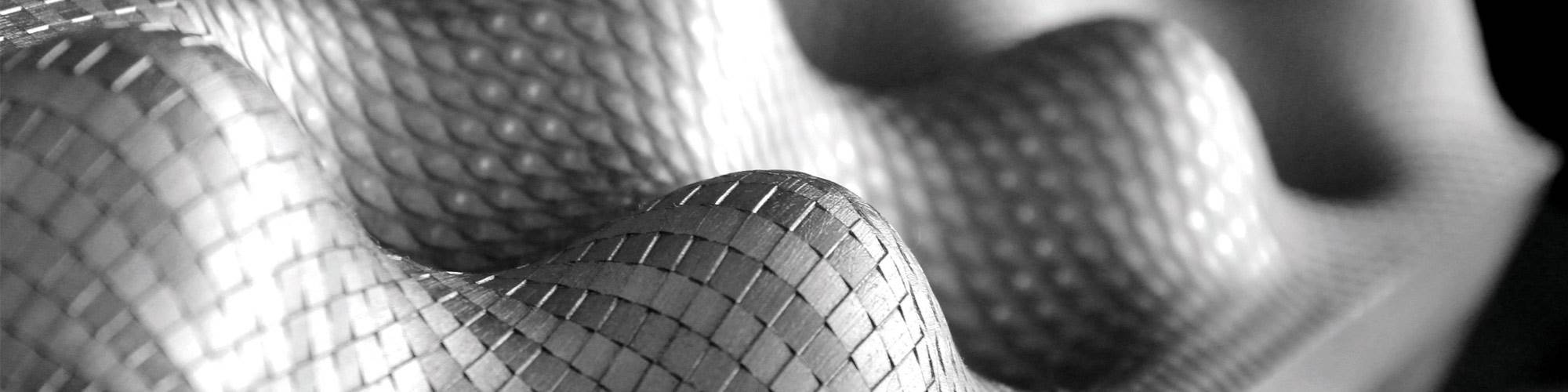

“The most current trend is fading structures, which become less prominent towards the edges and can only be digitally designed and laser textured (see photo), which is what our four designers are mainly working on right now,” Reichle says. “We created our in-house design department in 2017, which is what sets us apart from the competition. Without good in-house product designers, who have a particular liking for details, you should not even consider investing in a laser texturing machine. We work closely with automotive OEMs, have regular meetings and help them to reduce a car’s production costs by replacing expensive interior materials. We also work to differentiate so-called “carry-over parts” (which are used in medium-sized and expensive cars to reduce costs) by creating different surface structures that vary in gloss, look and feel. However, whether we design a surface for a lipstick, a high-pressure cleaner or rear spoiler, we invest up to 100 hours in creating the perfect surface. We concentrate on the surface and nothing else.”

We concentrate on the surface and nothing else.

If, for instance, a customer wants to recreate a certain leather grain structure, the design team scans the original sample and optimizes the resulting greyscale bitmaps. The designers work on a micron-level to create complex contours with technical or decorative digital structures. The resulting greyscale bitmap is high-res with a size of many gigabytes, Reichle explains. The three- or five-axis laser system converts each greyscale to height information. If a grain structure is 50 microns deep, the laser machines 40 to 50 different greyscales to achieve the desired structure.

“In comparison, manual etching is limited to three or four detail stages the user can control, while the rest of the structure is created randomly by the acid. The designers can also design the texture exactly. For example, if they locate the radius on or next to an edge, they can precisely separate the polished areas from the textured ones,” Reichle says.

After the design stage, the mapping process starts. A special mapping software, which is usually provided by the laser machine provider, is used to map the texture design with the mold CAD data. The software digitally applies the greyscale bitmap to the complete mold cavity, just like a foil used in etching. The software then optimizes the mold data, repairs mesh structures and eliminates warpage to make sure that a square structure remains square even on a spherical surface.

Reduced Lead Times

The design specialists need about two weeks to present the customer with a sample. "The big advantage is that we can develop design proposals long before tooling is in the manufacturing process, and the customer sees in advance how the surface texture of his product will look,” Reichle explains.

Once the customer approves the design and clarifies all other formalities, and the tool arrives at Reichle, they immediately deliver it to the laser system and begin the process. Lead times are reduced from two to three weeks to a couple of days compared to using conventional etching processes. The laser machines work 24 hours a day.

Reichle uses GF Machining Solutions’ pulsed fiber laser systems. As soon as the laser beam hits the surface, it vaporizes the material with an accuracy of up to 1 μm. The fiber laser is a wear-free laser source that ensures stable ablation over a longer period.

Consistent, Transparent Data

An equally great advantage of a laser-textured surface according to Reichle is reproducibility because the data is consistent, transparent and always available. The error factors are very small, and the process is 100-percent repeatable.

Reworking and repairs are also easy to carry out. Reichle explains, "We weld material to a damaged or worn part of the mold, then we reprogram the machine from the existing dataset, define the area, and off we go. The machine finishes most of the work. Manual work is only needed in the last step. Designers must rework the transitions so that the repair becomes completely invisible.”

Meanwhile, the small but rapidly-growing family business dedicates much of its manpower to the laser texturing business. And there is no end to this rapid growth in sight. Reichle and his young team (most employees are under the age of 30) have fully digitalized the business and aim to develop an intelligent database with an integrated product-configuring function, which will contain all necessary information to create the perfect structure.

“The customer will have to provide us with information like what texture he requires, what degree of gloss level, material, what tool steel he uses for the mold or what the molding temperature is supposed to be, and the database calculates the right manufacturing parameters. People make mistakes, and although that’s what we live from in our repair department, our vision is to eliminate these mistakes and create the perfect surface.”

Related Content

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreWhat Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreQuestions and Considerations Before Sending Your Mold Out for Service

Communication is essential for proper polishing, hot runner manifold cleaning, mold repair, laser engraving and laser welding services.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More