How to Deal with Graphite Dust, Part 1

A review of the characteristics and considerations when handling graphite dust.

Dust, a common household word that can be defined as a finely powdered substance of various matters often suspended in the air. This is no different with the dust generated when machining EDM electrodes. Anyone that has machined graphite knows that the particles generated from the machining process are very fine and have a tendency to remain airborne. However, unlike common household dust, graphite dust has characteristics that must be taken into consideration. This is the first of a two-part article that will discuss these characteristics and hopefully answer often asked questions when dealing with graphite dust.

Hazard or Nuisance

Perhaps the most common concern when dealing with graphite dust would be if it is considered as a hazard to the human body. To answer this, we must first understand that there are two types of graphite: natural and synthetic. The graphite used to fabricate EDM electrodes, and thus produce machining dust is synthetic graphite and considered to be a biologically inert material and producing dust classified as a nuisance instead of a hazard. Since the most common isotope in graphite is carbon, the human body does not recognize this as a foreign substance and will not attempt to reject it. The human body is in itself primarily carbon and is very compatible to the inert carbon material in synthetic graphite1.

While every measure should be taken to capture the dust at the source, this is virtually impossible and some amount will surely escape into the surrounding atmosphere. Due to the miniscule size of the dust particles, these may not be visible to the human eye. Graphite dust may be irritating to the eyes and could possibly cause stinging, watering and redness. Contact with this dust may be abrasive and mildly annoying to the skin, but absorption is unlikely2.

There is always some form of health concern associated with any type of overexposure and a nuisance dust is no different. For this reason, exposure guidelines for graphite dust have been determined and identified in the Material Safety Data Sheet (MSDS). As identified by the American Conference of Governmental Industrial Hygienists (ACGIH), the exposure guideline for time-weighted average (TWA) for graphite dust over an 8-hour period is 10 mg/m³ total3.

At this concentration, the graphite dust would be thick enough to hinder visibility. Having a concentration of this magnitude in a manufacturing environment is unlikely, especially if some type of dust collection system is in use.

Excessive exposure to graphite dust over extended periods of time can cause a chronic and more serious condition known as Graphitosis, which is a form of pneumoconiosis. This condition arises when inhaled particles of graphite are retained in the lungs and bronchi. Hazards such as Graphitosis have typically been associated with natural graphite, but have been associated with synthetic graphite in extremely rare instances3. Natural graphite contains crystalline silica that precipitates Graphitosis. This is not found in synthetic graphite or any dust produced by machining synthetic graphite. Long-term inhalation studies in rodents have not shown graphite dust to have serious health effects; however, air quality samples should be taken on a regular basis to monitor the concentration of airborne graphite dust.

NOTE: Special considerations should be taken into account when dealing with graphite impregnated with other materials, such as copper or Tungsten. Follow the health and safety guidelines for the material that has been impregnated into the graphite.

Dust Collection

Aside from the need to capture machining dust to maintain a clean shop environment and protect employees, another critical need for dust collection is to prevent the graphite particles from entering into electrical housings, control panels and switch boxes. By nature, synthetic graphite is electrically conductive and could create a myriad of problems if allowed to accumulate in areas that have a tendency to “short out” when in contact with foreign conductive materials.

There are primarily two methods for controlling graphite dust during the electrode fabrication process. The first method is to use high air velocity with a dust collector. High-speed machining centers designed for machining graphite come already equipped with a dust collection system that evacuates the dust with a powerful vacuum. However, conventional machining centers such as mills, band saws or grinders must be equipped with a type of secondary collection system. Portable units are ideal for shops that only do a limited amount of graphite machining since the unit can be moved from one machine to another as needed. Contrary to common belief, an off-the-shelf shop vacuum system is not adequate for graphite dust as the filtering system is generally not suited to collect the fine particles of graphite. To be efficient, a portable vacuum system must be equipped with a High-Efficiency Particulate Air (HEPA) filter that satisfies certain governmental standards of efficiency. In order for a filter to be qualified as a HEPA filter by government standards, it must be capable of removing 99.97 percent of all particulate matter in excess of 0.3 microns.

Fixed System

The best system for shops heavily engaged in graphite machining is a fixed unit with sufficient vacuum to draw the dust from the machine, through the duct work and into a collection bin. The recommended speed for capturing dust at the machining center is a minimum air velocity of 500 feet per minute. Once the dust enters into the duct work, there should be a minimum air velocity of 2000 feet per minute in order to prevent the dust from settling out of the air stream prior to entering the collection bin.

The air velocity is determined by the amount of graphite dust in the air and relates to the rate of material removed at each machine. A recommended source of information for designing dust collection systems is “Industrial Ventilation: A Manual of Recommended Practice by the American Conference of Governmental Industrial Hygienists”.

Wet System

The second method for dust control is to use a “wet” system to saturate the area around the cutter part with a liquid to prevent dust from entering into the surrounding atmosphere. The dust comes in contact with the fluid being used and is flushed away to a collection unit. While this can be an effective use of dust control, one must keep in mind the ability of the fluid to “wick” or be absorbed into the electrode material being machined. If this occurs, then the fluid must be removed prior to the electrode being placed in the EDM or it could contaminate the dielectric oil.

In a wet style dust collection system, a water-based solution should be used as this fluid does not wick into the graphite as easily as an oil based solution. Regardless of the type of solution used, the electrode material should be allowed to dry sufficiently prior to EDM. In order to expedite this process, the material could be placed in a convection oven for approximately one hour at a temperature slightly exceeding the vaporization point of the solution. In no case, should the oven temperature exceed 400°F as this causes the material to oxidize and erode away. As an added note, compressed air should never be used to dry off an electrode as the air pressure only serves to force the fluid into the structure of the electrode.

In part two of this article, we will examine the explosive potential of graphite dust and how to dispose of remnants that may be accumulating around the shop.

References:

1 Controlling Graphite Dust During the Machining Process; Moldmaking Technology, January 2000

2 Graphite electrodes used in electrical discharge machining generate a lot of dust, what to do with it? http://global-plastic-injection-molding.com/graphite-electrical-discharge-machining.html

3 MSDS: Poco Graphite Synthetic EDM Grade

Related Content

Treatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

Read MoreFundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreAdvantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

Read MoreRead Next

How to Deal with Graphite Dust, Part 2

A review of the explosive potential of graphite dust and how to dispose of remnants that may be accumulating around the shop.

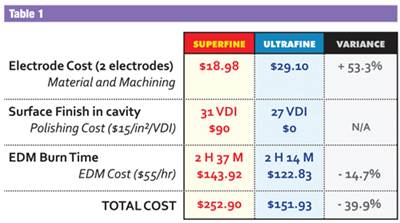

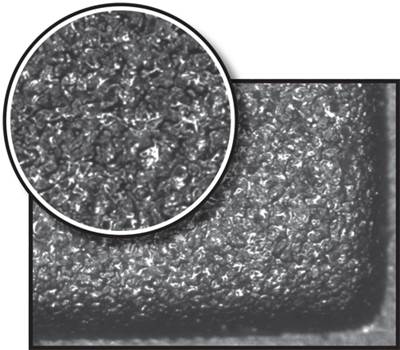

Read MoreElectrode Material Effect on CNC EDM, Part 1

When all the factors of the EDM process are taken into consideration, savings on the electrode material cost can result in a much larger overall cost.

Read MoreElectrode Material effect On CNC EDM, Part 2

A discussion of the reasons why the use of more, economical electrode material is not always the most cost-efficient means of CNC EDM

Read More