Electrode Material Effect on CNC EDM, Part 1

When all the factors of the EDM process are taken into consideration, savings on the electrode material cost can result in a much larger overall cost.

Unrivaled advancements in EDM technologies have become an intrinsic means of ensuring success in today’s global competitive environment. Shops today must find a method of reducing manufacturing costs while boosting productivity and providing a quality mold, on time while meeting ever-increasing demands in customer specifications. Oftentimes this entails the upgrading of capital equipment to current technological capabilities. This first of a two part series will examine the use of adaptive control and introduce the effects that an electrode material may have on the efficiencies of this function.

What Is Adaptive Control?

While much has changed in die sinking technology, one of the foremost advancements is the development and continual improvement of adaptive control, or fuzzy logic, to eliminate the guesswork and allow the machine to take control of the metal erosion process.

Historically, the EDM operator was required to be diligent in monitoring the EDM application and have the necessary skills to correct any complications in the EDM cut. These talents are hard to find in the current labor market and come at a high price. This facilitates the need for improved capabilities in EDM CNC control. With the caliber of adaptive control in today’s EDM sinker, the machine continuously monitors the EDM gap in search for signs of impending failure. Once identified, the sinker automatically adjusts the machining conditions to overcome the threat; therefore, allowing the operator to focus on other tasks. Unfortunately, this often results in complacency of the operator while believing the adaptive control of an EDM sinker will also provide the most efficient means possible to complete an application.

With this, a common occurrence is to use a more economical, lesser quality electrode material. After all, the sinker has the ability to overcome any complication in the cut and will be able to complete the task at hand, right? While this may be true in some cases, the fact is that the electrode material will affect the machine’s ability to fully optimize the EDM process and provide the most cost-effective means of completing the application. In other words, the adaptive control of the EDM sinker will optimize the application only to the level of what it has to work with.

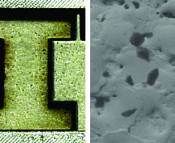

The purpose of the adaptive control in an EDM sinker is to read the conditions of the EDM spark and translate these conditions into digital signals that are fed into the machine’s controller. The controller translates these signals, determines the efficiency of the EDM cut and makes adjustments accordingly. One of the conditions monitored by the machine’s adaptive control technology is contamination in the gap. If excess contamination in the gap is present, this creates the potential for an EDM arc or diminished performance. The controller must then make adjustments that do not affect the overburn or surface integrity of the workpiece. This generally involves changes in the gap voltage, increasing the off-time, altering the jump cycle or a combination of any of these.

While this may rectify the issue, the problem is that none of these are conducive to truly optimizing the EDM performance. Using lesser quality electrode materials often creates the need for the machine’s controller to make continual adjustments; therefore, slowing down the EDM cut.

The old adage, “If it ain’t burning, it ain’t earning” comes to play here. For example, as the controller increases the off-time in an EDM cut to overcome excessive contamination in the gap, the corresponding duty cycle of the electrode material is reduced and the EDM cut is slowed.

Spend a Dollar to Save a Dime

Frank-Peter Amdt, BMW’s Production Chief once said, “Anyone who saves money in the wrong area in tough times is putting his competitiveness at risk over the long term.”

In order to calculate the true cost of the EDM application, shop owners must not only take into consideration the cost of the electrode material and machining, but should also account for the cost of the EDM time and any polishing that may be required in the end. Moving to a lesser quality material just to save a little in the price of an electrode may end up costing more in the long term and reduce the competitive advantage a shop may have.

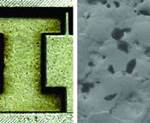

Taking Mr. Amdt’s statement in mind, a test was conducted to evaluate the effect of a more economical, lesser quality electrode material on the adaptive control function of the EDM sinker. Materials from the superfine and ultrafine classifications were used and a ribbed electrode was programmed to provide a depth of 1.5" with a surface finish of 27 VDI.

The cost difference between the two electrode materials seems considerable, so why use a more expensive material when the adaptive control of the EDM sinker is projected to complete the task at hand? As we can see in Table 1, the use of the more economical superfine material did not have the cost efficiency that was expected. This material did not achieve the required surface finish and took longer to reach the final depth. The added cost of polishing the cavity and extra EDM time actually caused this application to lose money. The use of a lesser quality material could be justified if the material cost is all that was considered. However, we can see that a mere savings on the electrode material cost can result in a much larger overall cost when all the factors of the EDM process are taken into consideration. In the case of this example, for every dime that is saved on material cost, a dollar is spent in the overall manufacturing cost.

Summary

As illustrated, the use of inferior electrode materials interferes with the ability of the sinker to correct the problem, and therefore, often results in increasing the EDM cost. The second part of this article examines the method and results of the testing that was conducted and will provide an in-depth explanation of why the use of more economical materials may not provide an overall advantage in the total manufacturing costs.

Read Next

Electrode Effect on a Quality EDM Finish

The production of fine surface finishes in the cavity does not come with the technological improvements of the EDM sinker unless an electrode material of higher quality is used.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More