Making an informed decision about adopting any new technology requires a solid understanding of the pros and cons, but when it comes to choosing the proper actuation method, the pros and cons get a bit more complicated as they vary across the supply chain — the mold builder, the molder and the end-user of the molded parts.

Molder Matters

Molders see many benefits with electrically-actuated hot runner systems, including the clean, quiet, energy-efficient electric actuators and the elimination of the risk of oil leaks due to the removal of hydraulic fluid from the process. Energy efficiency is another benefit. Hydraulic power requires large pumps with electric motors that continuously run, whereas electric actuators require only a small fraction of that power.

A key benefit is the higher level of repeatability, both drop-to-drop and shot-to-shot. With hydraulic actuators and pneumatic actuators to an even higher degree, there is a significant lag time between when the signal is sent and when the pin starts to move. This lag time is an aggregate of many smaller delays, each with its own variability. Therefore, the overall lag will also have variability. Testing shows that the average lag time of a pneumatic actuator is about 0.350 seconds versus an electric actuator at about 0.002 seconds. The shorter lag time associated with electric actuators leaves little room for variability increasing repeatability. When the timing of the valve gates is critical, this improved repeatability can increase consistency with far less scrap.

The greatest benefit is complete pin control.

Electric actuators are consistent and responsive from the very first shot, unlike hydraulic systems, which require time for the hydraulic fluid to reach a temperature equilibrium. Applications with critical pin timing may require adjustments to maintain part quality once the hydraulic fluid heats up and the valve pin speed changes. Electric systems do not require this adjustment as they perform the same from the first shot of the day to the last shot of the day.

The greatest benefit is complete pin control. With an electric actuator, movement is no longer restricted to a simple open and close at full speed. Now the molder can control the speed, acceleration and stroke of the pins, and even program complex movements to manipulate the filling and packing of the mold.

Although the number of pin movement variations is infinite, there are three common types used to manipulate melt filling and packing. Figures 1, 2 and 3 illustrate pin position versus time. The vertical orange line indicates the velocity/pressure switchover position.

Figure 1 shows the pin opening at a reduced speed for the first few millimeters. Once the pin reaches a specified distance, it continues opening at full speed and then closes at the end of the hold. This type of movement is commonly used on delayed pins during cascade molding because pressure builds up behind the delayed gates. If those delayed gates are opened at full speed, there is a sudden release of pressurized melt into the cavity, which causes an abrupt flow front acceleration, resulting in a line of differential gloss on the molded part. Controlling the opening speed of the pin, as shown in Figure 1 will control the release of pressurized plastic, eliminating the sudden acceleration of the melt front and the cosmetic defect that it creates.

Figure 1. Pin opens at a reduced speed for the first few millimeters. Figures courtesy of Synventive Molding Solutions.

Figure 2 shows the pin opening quickly to an intermediate open position where it stops and stays until the screw reaches the switchover position, which reduces the amount of material flowing out of this gate during the fill. At switchover, the pin opens fully to allow for unrestricted packing. It then closes at the end of the cycle. This type of profile balances family tools or reduces the amount of flow from specific nozzles when filling a complex geometry or moving a weld line.

Figure 2. Pin opens quickly to an intermediate open position where it stops and stays until the screw reaches the switchover position.

Figure 3 shows the pin opening quickly to full stroke, as in a conventional process. At switchover, the pin closes part way and remains there until the end of hold and then closes fully. This type of profile can be used to restrict packing pressure to the area of the part near this gate. Family tools with different wall thicknesses or complex parts with areas that easily flash and other areas that need significant packing pressure can benefit from this type of profile.

Figure 3. Pin opens quickly to full stroke as it would in a conventional process.

Multiple flow manipulation types can be programmed into a single pin move, which allows the shop to balance extreme family tools, fill complex geometries and reduce clamp force requirements.

Mold Builder Bias

Designing and building a mold with an electrically-actuated hot runner system can yield some significant cost savings, as gun-drilled hydraulic or pneumatic lines are no longer necessary. The slots required to run the wires from the edge of the mold to the motors are much smaller than traditional hoses, saving machining time. Mold assembly also takes less time because the electric motors plug into the junction box, eliminating any necessary plumbing to run air or hydraulics.

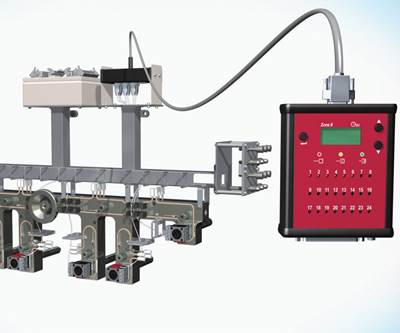

Electric systems can also save time during the initial mold sampling, which is often the mold builder’s responsibility. A conventional system requires valve pin adjustments when the mold is out of the press if they are not set perfectly, which often demands an additional sampling to verify pins are properly set. On many electric systems, you can adjust the setting of the pins directly from the controller between shots, eliminating the need to pull the mold to make changes.

End User Effects

The end-user of the molded parts also benefits from the use of an electrically-actuated hot runner system. For example, now that the molder can manipulate part filling and packing, part cosmetics are improved, dimensional tolerances are tightened and warpage is reduced.

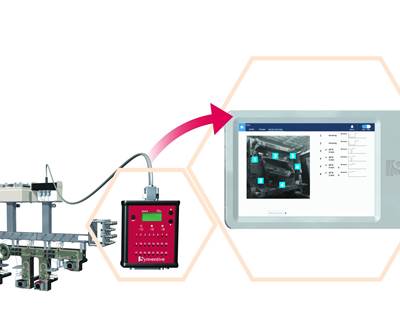

Per-part cost savings can also be achieved with an electrically-actuated hot runner if a shop uses a family tool to produce parts, for example. Or, the scrap rate is reduced, which may not be possible with conventional valve gating. Some electric systems will also record the pin movements from every cycle. So, if a bad part reaches the end-user, historical data can help identify what went wrong and potentially quarantine other parts of concern.

Lastly, electric motors are maintenance-free, unlike the seals of hydraulic or pneumatic pistons that operators must replace periodically.

Related Content

Reshoring Initiative Reports Another Stellar Year

According to the report, the IRA and Chips Act combined with deglobalization trends to boost reshoring in 2022 to another all-time high — up 53% from 2021’s record.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreUnited Grinding Announces Support for the Reshoring Initiative

According to the Reshoring Initiative, the rate of reshoring job announcements has grown from 10,000 per year in 2010 to 350,000 per year in 2022.

Read MoreFour Industry 4.0 Tech Adoption Insights from Indiana Plastics Manufacturers

As more plastics manufacturers step into the Fourth Industrial Revolution, insights have emerged about how best to approach the digital transformation journey.

Read MoreRead Next

Smart Tooling

Combining cavity sensors with hot runner valve gate control yields new applications and greater process gains.

Read MoreModular Technology on Demand

An upgradable approach to flow-control technology offers flexibility and could help ease the decision on whether the technology is worth the investment.

Read MoreHot Runner Technology Offers Complete Control of Molding Parameters

Synventive’s Synflow3 technology enables molders to slow the opening of the pin for a set distance and hold at that position until closing or alternating different moves within a cycle.

Read More