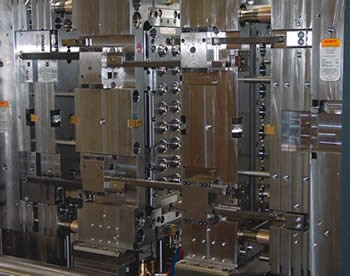

Spin Stack Mold Design Results in Longer Mold Life, Higher Cycle Times

For more conventional mold manufacturers that wish to find a new niche and offer more complex molds to their customers.

For more conventional mold manufacturers that wish to find a new niche and offer more complex molds to their customers, a proprietary Spin Stack technology for the design of stack molds has been developed that allows these molds to have better cycle times and longer life. This technology basically uses four-sided indexing core sets between the stationary and moving platens to allow for multi-component molding with decorating, coating, and/or in-mold assembly operations.

Developed by Gram Technology (Scottsdale, AZ and Copenhagen, Denmark)—a provider of molding solu-tions in the multi-component molding market—using this technology can have molds running more than 12 million molding cycles. According to Gram Technology Managing Director Jes Gram, stack molds multiply the number of usable mold faces and also permit molding the entire mold face with each material. “The new designs have a center platen that rotates on a vertical axis,” Gram explains. “Depending on the system, the center component can have either two or four faces and rotate 90° or 180° each time the mold opens.”

With this patented technology, the second and fourth (non-molding) sides of the center stack can be used for insert loading or cooling without increasing the cycle time both for one and multi component applications. This also gives a whole new prospective for high-speed in-mold labeling in stack mold configurations with tremendous cycle time and yield benefits. To support these applications the company also patented an ejector system that can eject parts to the side of the machine—simplifying part handling and giving better quality control when combined with a vision system.

Benefits

Gram notes that when compared to conventional rotary platens used for multi-component molding, the new rotary stack molds index much faster because of the “lower mass of the turning member.” Additionally, he explains that this technology requires the least mold-opening distance to permit the stacks to spin. “A two-part closure mold needs to open just 100 mm for its system to index,” Gram says. “This system is the most flexible on the market. Everything is contained in the mold—the turning mechanism, hydraulics and all of the components—so the technology can be used in any conventional press.”

Additionally, this technology can result in better part quality. “With the Spin Stack technology, the same hot runner system can be used to inject the second layer of the same material,” Gram comments. “Injection and cooling of a smaller volume of melt on each shot reduces the cooling time and chances of sink marks.”

Related Content

-

Editorial Guidelines: Editorial Advisory Board

The Editorial Advisory Board of MoldMaking Technology is made up of authorities with expertise within their respective business, industry, technology and profession. Their role is to advise on timely issues, trends, advances in the field, offer editorial thought and direction, review and comment on specific articles and generally act as a sounding board and a conscience for the publication.

-

MMT Chats: 4 Keys to a Successful Mold-Building Operation: Innovation, Transparency, Accessibility and Relationship

MoldMaking Technology Editorial Director Christina Fuges chats with Steve Michon, co-owner of Zero Tolerance in Clinton Township, Michigan, about the excitement of solving problems, the benefits of showing gratitude, the real struggle with delegation and the importance of staying on top of technology. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

-

MMT Chats: Solving Schedule and Capacity Challenges With ERP

For this MMT Chat, my guests hail from Omega Tool of Menomonee Falls, Wisconsin, who share their journey with using enterprise resource planning (ERP)—and their people—to solve their schedule and capacity load monitoring challenges.