With each transfer program, MMD conducts a full bench review of each tool to evaluate the tools and identify critical modifications. Photo Credit: Metro Mold & Design

Who is Metro Mold & Design (MMD) – Consumer & Industrial?

Ben Lampron, MMD VP of Consumer & Industrial: Metro Mold & Design (MMD), offers proven expertise across a wide range of capabilities, including moldmaking, injection molding, blow molding, thermoset molding, tooling repair and maintenance and engineering.

Based in Rogers, Minnesota, our business is made up of two divisions: Consumer & Industrial and Medical. In Consumer & Industrial, we specialize in high-volume, low-mix, highly automated molding solutions for plumbing, consumer goods, personal care products, medical packaging and more.

Our Consumer & Industrial facility houses a range of molding technologies supported by PLC automation, robotics, automated packaging systems and auxiliary equipment. We have an on-site quality lab and a dedicated tooling maintenance shop with a team of full-time mold builders who service and maintain molds.

We have more than 200 employees and two state-of-the-art facilities comprised of approximately 250,000 square feet.

Industry agnostic, we focus on programs where our approach can drive the lowest costs and highest quality. We spend a significant amount of time evaluating manufacturing parts at the lowest cost with optimal cavitation molds paired with the right tonnage injection molding machine. Our ideal program provides a high enough plastic part volume to maximize press utilization for the greatest economies of scale.

We do more than moldmaking and molding—we are a contract manufacturing partner focused on helping our customers design and execute programs that support key business goals.

MMD provides both mold building and molding services, which seems to be a trend the past few years and can be a powerful combination in today’s competitive landscape. Can you explain the history of MMD in moldmaking and molding?

Lampron: Our roots are in moldmaking. MMD started in our founder’s basement in 1973 and expanded into molding through strategic acquisitions. Today, our focus continues to be on providing a combination of these services to allow our customers to achieve their business objectives—whether it be reducing costs, maintaining supply, or ensuring consistent and reliable quality.

Can you explain the value-add this combination of services provides to your customers?

Lampron: In Consumer & Industrial, our tooling team services and maintains molds onsite to limit interruptions to supply and ensure optimal mold performance. This allows us to maximize press capacity, control the quality of our molded parts, maintain efficient, repeatable manufacturing programs and optimize program timelines.

Applying our knowledge of mold building to our molding processes, we also review programs holistically and partner with industry-leading tool builders to help create the optimal cavitation molds that we design.

Evaluating the program from start to finish—including part design, material characteristics, value-added services, labor requirements—results in programs that reduce long-term costs and promote continuous improvement.

What do you view as your chief competitive advantage(s)?

Lampron: Our specialization in high-volume, low-mix, highly automated plastics manufacturing—including standard press-side robots, automated packaging systems and PLC automation—coupled with the discipline from our 80/20 focus enables us to identify where we can produce the most significant sustainable value for our customers.

Our 80/20 focus places most of our efforts on our top customers, eliminating disruption from programs that are not mutually beneficial. This selectivity focuses our resources on programs to produce the most significant outcomes for our clients and our team.

We’ve learned to say “no” to programs that would create disruptions on the shop floor. Instead, we dedicate ourselves to programs where we can run full-press utilization with minimal changeovers that interrupt supply or require additional investments in labor, capabilities and processes.

Our goal isn’t to be everything to everybody or anybody. Our goal is to be the very best contract manufacturing partner on those jobs where we can drive the greatest impact with our high-volume molding efficiencies.

What is an example of one of the more significant, recent changes in your use of technology?

Lampron: We work with our clients to deliver customized work cells equipped with advanced manufacturing technologies and automation. This includes the optimal tonnage injection molding machines, PLC automation, packaging systems and conveyors, picking robots with EOAT, appropriate standard auxiliary equipment, boxing and more.

Being at the forefront of technology allows us to offer world-class, on-time delivery with minimal quality issues. Our investments focus on the repeatability of the process to eliminate scrap and unwanted downtime (for instance, producing a consistent 0.2% scrap rate for one consumer packaged goods manufacturer) and speed of delivery (achieving 99.9% OTD for that same customer).

Creating the right manufacturing environment, maintaining process integrity and meeting stringent demands led one of MMD’s recent tool transfer programs to successfully produce 4.92 million parts and an average scrap rate of 0.8%.

What is an example of one of the most significant, recent changes in your general approach to business?

Lampron: We continue to find ways to improve our organizational structure and approach to allow us to overserve our top customers. Our 80/20 focus enables our engineers to focus entirely on evaluating and improving customer programs, allows our operators to focus on value-producing work and empowers our team to work together to help our customers achieve their business goals.

Communicating openly with customers, we decline offers if we cannot be the low-cost provider. Instead, we recommend how they could strategically align their supply chain for the greatest cost savings and value. By focusing on programs where we can provide the most significant value—and walking away from high-mix, labor-intensive, short-run projects—we can provide unparalleled engineering and customer support. In this way, we build long-term relationships with customers who share our business philosophy.

How do you expect your business to evolve in the next 3-5 years?

Lampron: Given the economic, cultural and political environment offshore, we anticipate that more and more customers will want to control their supply chains with reliable U.S. manufacturers. A strong advocate for revitalizing America through manufacturing, we see increased work from offshore. Our investment in automation and our focus on programs where we can produce the most significant outcomes make MMD a strong, long-term partner.

Is your company having a difficult time finding and attracting new employees? Please tell us how you are, or are not, addressing the skills gap in the industry.

Lampron: Despite the challenges of the pandemic, we are generally fully staffed. We invest in our current staff and new hires through on-site training and career development. Furthermore, we work to define specific career paths for our team and regularly offer stretch assignments that develop their talents. We encourage and fund off-site training that makes sense and regularly offer on-site events that create cross-training opportunities.

Describe the most interesting/notable mold project your company was awarded.

Lampron: We recently teamed up with an HVAC and plumbing parts manufacturer on a tool transfer program that has evolved into a critical, strategic partnership based on the program’s success.

The initial program was for the annual production of over five million parts of plastic fitting components. Having received rundown tools, an outdated automation system and difficult materials, we had to find a way to hold very tight tolerances and achieve on-time delivery without compromising quality.

The steps we took to complete this tool transfer successfully include a holistic tooling analysis to uncover the identification of potential issues; an investment in upfront engineering, where we evaluated the materials and volume; and the creation of a customized work cell that housed three 200- to 350-ton injection molding machines, automated packaging systems and specialty cooling conveyors.

Combining a wide range of in-house competencies with the discipline to drive the greatest value, we quickly and efficiently executed the tool transfer program. The first year saw successful production of over five million high-quality parts while maintaining an average scrap rate of 0.8%.

In the year since the program’s inception, it has grown to be one of MMD’s largest today.

Related Content

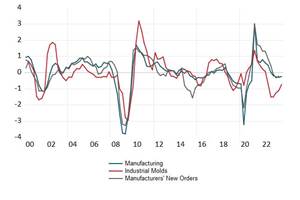

Navigating Economic Resilience and Consumer Trends

Consumer behavior provides mold builders insight into the evolving market dynamics of goods and services that helps strategic planning.

Read MoreHammonton Mold, ADOP France Forge Strategic Partnership in Injection Blow Moldmaking

Hammonton Mold Inc., a leading full-service mold shop based in New Jersey specializing in injection blow molds (IBM), proudly announces its official partnership with ADOP France, a prominent IBM mold manufacturer based in Normandy, France.

Read MoreMMT Chats: Digitalizing Mold Lifecycle and Process Performance

MMT catches up with Editorial Advisory Board member Bob VanCoillie senior manager of Kenvue’s mold management center of excellence outside of Philadelphia to discuss mold management via tooling digitalization and OEM expectations and opportunities.

Read MoreDomestic Collaboration Yields Efficiency and Budget Gains For Innovative Tooling Project

Pyramid Molding Group and Lettuce Grow partner to develop optimal tooling for a compact Hydroponic Farmstand.

Read MoreRead Next

Diversification and Departmentalization Drive Growth for Wisconsin Mold Builder

New ownership at Innovation Mold & Design (IMD) grows the company by investment in technology that serves a departmentalization and diversification, business model.

Read MoreA Technical and Business Approach to Moldmaking Increases Growth Opportunities

Next-generation ownership at Kingson Mold and Machine changes culture to deliver optimized, definable and repeatable productivity solutions.

Read MoreTraining and Education Is Major Focus with the Tooling Divisions of The Plastek Group

This manufacturer of plastics packaging also manufactures injection and injection blow molds across three facilities employing more than 125 well-trained toolmakers, engineers and project managers.

Read More