Kingson Mold and Machine Inc. was founded in 1977 by Jack and Greg Rex in Brea, California. Today Greg's daughter Kaci Miller leads a team of 25 employees, designing and building LSR, compression, transfer, rubber and plastic injection molds and die-cast dies. Images courtesy of Kingson Mold and Machine.

What do you view as Kingson Mold and Machine's chief competitive advantage(s)?

Kaci Miller, President, Kingson Mold and Machine: Throughout each job awarded, our team offers an unmatched depth of experience across many areas, including design, prototyping, mold making and molding processes. We not only create molds but also develop an optimum process window to ensure the highest sustainable production yields at the lowest possible cost. At Kingson, we offer problem-solving ideas and personalized tooling solutions that add value and profit without sacrificing expectations.

Kingson’s inspection and polishing department was redone to accommodate all inspection needs for in-process and final inspection.

Where did you work before Kingson, and when did you officially start working at the shop?

Miller: Before joining Kingson, I worked in property management. I started as an assistant manager, quickly moved up to a property manager and then rose to corporate and oversaw several different properties. However, throughout all that time, my father always would ask me to come work at Kingson in sales.

Finally, in 2011, I came on board. It was at this time that my father was diagnosed with stage-four cancer with no clear timeline. It was a challenge coming into a company in this way and being the daughter of the owner. I never wanted anyone to think that I felt I was entitled to take over the shop. I genuinely believe that I earned the position of president by 2014.

I didn't come on as taking over the company. I worked a few years in sales, marketing and strategic planning to learn the ins and outs of the industry. I also leaned heavily on Kingson project manager Joseph Solorio for vital training in the business and technology.

“We are fully capable of doing anything here. Before, we just had mills, but today we have our high-precision area with trained operators doing extremely hard, intricate work that we were not known for prior to this culture shift.”

You mention the value of a solid right-hand man? Who is that and why?

Miller: Joseph Solorio is my right-hand man. He started two weeks before I came into the company overseeing sales and learning the industry. His cousin came in for an interview, and Joseph had just left his father's shop, and he tagged along for that interview. We ended up hiring him over his cousin. He came from the plastics industry and had experience with liquid silicone rubber (LSR).

His first month here, we awarded him Employee of the Month due to his thoroughness. We just meshed very well, and I liked his work ethic. He loves training and new technology while respecting traditional moldmaking practices. Through the years, he was one who always wanted to get new equipment, taught me machining and programming basics and trained me on the ins and outs of this industry. From the beginning, he was my right-hand man.

Joseph's expertise is technical machining and moldmaking, and my expertise is the sales and business side of Kingson. Joseph heads up manufacturing, and I took control of the office and sales, but my presence is seen on the floor every day. We run the floor together. I think it's very important that my presence is known out on the floor despite Joseph assigning the jobs. The two perspectives make us stronger. We challenge each other and hold each other accountable.

Every job runs through Kingson’s precision grinding department.

How did the culture shift when you took over?

Miller: One of the more significant challenges was getting the workforce to move beyond its lack of outside-the-box-thinking when it came to working with a specific type of customer and a certain type of work. My management experience also brought structure to the shop—upgrading its handwritten bills, traditional Rolodex approach to business contacts and technology investment strategy.

We've been through so many growing pains with the loss of longtime employees who were working against us. We were challenged with some past customers also. Several times I had to explain that we are a completely different Kingson than what they knew. The vision has also changed, and I've had to fight along the way to keep that vision going.

Today, Kingson is motivated to be better every day. I feel that we are a family. I look down at the shop, and you can see all the guys we have here now love coming to work, and they love working together. I don't remember seeing that when I first came into this role.

And we are fully capable of doing anything here. Before, we just had mills, but today we have our high-precision area with trained operators doing extremely hard, intricate work that we were not known for prior to this culture shift.

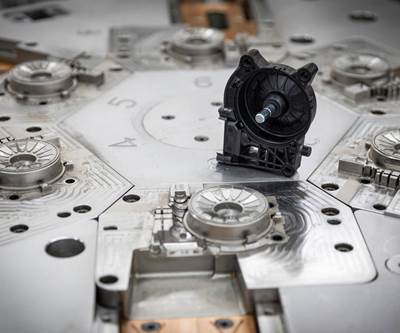

A threaded die cast insert.

What was the first change you made?

Miller: We had two EDMs that were always producing pits, so with a recommendation from Kingson's project manager, Joseph Solorio, I sold them both without my father's approval. This was when my father saw that I had the company's best interest at heart and the financial aspects of the business top of mind.

Selling these machines and investing in new EDM technology also helped to bring the company together. The people who were against new technology and resistant to change left the company, and we launched our high-speed precision department for which I headed up sales. This effort demonstrated what Kingson could become.

Describe the most recent change in your use of technology.

Miller: We have added a considerable value with the outgoing inspection of each job that leaves our facility. We check every mold while in process and at completion. We purchased a new Zeiss CMM and hired a very talented inspection manager that generates an easy-to-read report for our customers to know the job was done right.

Kingson Mold and Machine continually invests in new machining technology for its high-speed precision department where they complete all the finishing work—including a Sodick high-speed mill, sinker EDM, wire EDM and a Zeiss CMM.

How do you expect your business to evolve in the next 3-5 years?

Miller: Kingson is at capacity for space right now. We are continuing to work with the space we have, but we realize it restricts us from purchasing additional equipment. If we want to continue to grow, we must move into a larger facility, which will allow us to take on new customers and add more talent. Our three-year plan includes investing back in the company and looking at a new building (25,000-30,000 square feet) in the Chino Hills area. We are also considering molding for sampling, and small production runs as well. We are up for challenges and continue to push ourselves.

How are you addressing the skills gap in the industry?

Miller: It’s all about who you fill the gap with. The skills gap has always been a struggle in this industry because it is not something you can learn overnight. It takes patience, skills, and we do not want mediocrity. We are always looking for individuals who push themselves daily, strive to be the best and are willing to take on new challenges.

Describe the most interesting/notable mold project Kingson Mold and Machine, was awarded.

Miller: We have been challenged this past year with what we thought would be an R&D project involving prototype tooling and production molds for an artificial intelligence-assisted handheld ultrasound tool used on the heart, lungs and body. Due to COVID-19, the FDA approved this project earlier than expected, so the pressure to complete production tools was challenging. However, our team came through, and in the end, we have a satisfied customer with a top-notch product.

What do you believe is the key to individual success at Kingson Mold and Machine?

I'll take the words of Joseph, who always says, "I want to leave at the end of the day, knowing that I earned my paycheck." I think that's such a big statement and speaks volumes about the team here. I love being a team player. I'm very proud of where we've come from. My word means something, so I make sure that if I am going to say something, we stick by it.

Related Content

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreThe Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreWhat You Should Consider When Purchasing Modified P20 Steel

When buying P20 steels that have been modified, moldmakers must be aware of the variations and key issues that affect delivery, cost and lead times.

Read MoreRead Next

Using the Right Technology at the Right Time and in the Right Way

Michigan mold and die maker puts its engineering expertise to work for each customer.

Read MoreMichigan Moldmaker Produces Tools Onshore and Off

Rather than fighting offshore competitors, Liberty Molds has spent the last 15 years producing injection tools in both China and Michigan—and it’s paid off.

Read MoreLS Mold Inc. Discusses the Importance of Flexibility and Being Helpful

Rolling with the tides: how a Michigan mold builder has weathered economic storms for over 50 years

Read More