Zero Tolerance LLC of Clinton Township, Michigan, produces injection tools for customers in the medical device, automotive and defense industries and custom injection molds parts for customers in the oil and gas, prototyping and consumer goods segments. Photo Credit: Zero Tolerance LLC

Moldmaker and injection molder Zero Tolerance LLC was founded in 2011 in Kansas by co-owners Steve and Jamie Michon, who moved the company back to their native Michigan the following year. Zero Tolerance operates out of a 9,500-square-foot/883-square-meter building, employs 14 associates and produces 50 small-to-medium-size injection molds per year, typically with one to four cavities and lots of side action for straight injection and two-shot/overmolding. Initially, the company made injection molds and an occasional die to cast zinc, aluminum or magnesium. However, in 2019, it won a job requiring toolmaking plus injection molding services, and parts for that customer have been in continuous production ever since.

Now equipped with two injection presses (100 and 138 tons with 6-ounce/177-cubic-centimeter maximum shot size), Zero Tolerance accepts custom injection molding jobs ranging from 300 to 1 million parts per year and molds polymers ranging from olefins to high-temperature polyamides. Eight CNC machining centers support moldmaking work — six units are three-axis and two are five-axis machines, with one three-axis CNC dedicated to machining electrodes for the company’s two sinker EDMs. An additional wire EDM and an EDM drilling machine round out key equipment.

Typical Zero Tolerance molds are one to four cavities with significant complexity and side action sized for presses of 500 tons and under, but the shop’s sweet spot is between 200 and 300 tons. Most molds are for straight injection or two-shot/overmolding. Photo Credit: Zero Tolerance LLC

Additionally, the company offers tool and part design services, engineering changes and mold repairs. It also provides local shops with sinker, wire and EDM drilling services. During the pandemic, Zero Tolerance began using polymer additive manufacturing (AM) for prototyping/proof of concept work as well as participating in a distributed manufacturing program called Project Diamond, where all participants print the same part at the same time to support particular programs, such as producing medical equipment during the pandemic and tourniquets for the war in Ukraine.

The company also designs and prints its manual end-of-arm tooling, which Steve says has increased molding throughput by 50%. In addition, Zero Tolerance has designed metal AM slides with conformal cooling that were printed by an outside service, then finish machined in-house and installed in company molds.

The Michons also own Sunspot Tooling Systems. Now co-located in the same building as Zero Tolerance, Sunspot sells tooling, fixturing and mounting components for electrodes and small inserts for sinker and wire EDM. In the same building is strategic partner Dane Spotting + Benching LLC, which provides all of Zero Tolerance’s polishing and benching work and servicing other local toolmakers.

Reducing Setups, Expanding Capacity

With limited floor space and a small but talented team, the Michons have to be strategic about adding capacity and growing their business without breaking their budget or necessitating the acquisition of a new building. Circa 2021, Steve started looking for a new five-axis CNC mill.

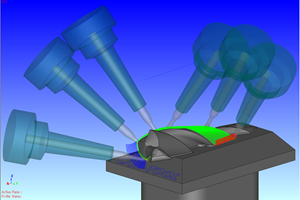

The team already had one five-axis machine, which had proven highly useful at reducing setup times and increasing output. However, a small machining envelope meant that mill couldn’t cut the 12 × 12 × 4-inch/305 × 305 × 102-millimeter blocks that Zero Tolerance typically uses for its molds. Hence, that machine strictly cuts small inserts and slide details. Still, as Steve’s wish list for his next CNC purchase took shape, he wanted true five-axis capabilities in a vertical mill that was versatile enough to square blocks and drill waterlines, and rigid enough to rough mill, yet accurate enough to finish mill blocks.

Zero Tolerance co-owner Steve Michon was excited when the company took delivery of a new YCM RX65 five-axis mill purchased during the IMTS 2022 trade show. Photo Credit: Zero Tolerance LLC

In short, he wanted one machine that could do it all, reducing setups and increasing accuracy. Since the Michons planned to replace an older three-axis machine, the new machine had to maintain the tight dimensions that Zero Tolerance relies on to satisfy customers in medical, defense and automotive. Finally, it had to be compact enough to fit in limited floor space.

Steve evaluated products from five different industry-leading machine tool companies. Still, none offered everything on his wish list — that is until he started talking with Keith Kauzlarich, sales manager – Michigan/SW Ontario at YCM (USA) Inc. and the YCM Alliance. The latter offer high-speed, high-precision YCM-brand CNC machines from Yeong Chin Machinery Industries Co. Ltd. (YCM) as well as complementary brands of machine tools designed to provide customers with application-based solutions. Kauzlarich had sold the Michons their first five-axis machine.

Fast, Accurate, Flexible

Founded in Taiwan in 1954, with technical and sales centers and subsidiaries in China, Malaysia, Vietnam, Europe and the U.S., YCM’s machining centers are known globally for their precision, rigidity and reliability. The company is one of the two largest CNC machine tool OEMs in the Pacific region, offering more than 70 different makes/models, including three- and five-axis vertical and horizontal machining centers, double-column vertical machining centers and turning centers.

For its YCM RX65 five-axis mill, Zero Tolerance co-owner Steve Michon selected a FANUC controller, added a 60-tool magazine, upgraded to a 15,000-rpm spindle and added a chilled coolant system. Photo Credit: Yeong Chin Machinery Industries Co. Ltd. (YCM)

YCM produces 250 CNC machines per month, is said to be the largest user of FANUC controllers in the region plus owns one of the few foundries in the region licensed to use the patented Meehanite process to produce high-strength, highly consistent iron castings for demanding applications. As such, YCM is vertically integrated from the foundry to producing its spindles, smart automation controls and Internet of Things (IoT) platform. The YCM Alliance provides machining solutions for mold/die, general parts and ultrahigh-speed machining applications across multiple industries through a dedicated dealer network.

A leader in quality, YCM says it was the first Taiwanese machine tool OEM to qualify for ISO 9001 and ISO 14001 certification. It stress relieves all castings and hand scrapes in 100% of joint dimensions for high precision, builds all equipment under climate-controlled conditions and tests every part as components are produced. The company has been selling in North America since the 1970s and has more than 1,000 machines installed in Michigan alone, explains Kauzlarich, who worked closely with the Michons to understand their requirements and help them find the right machine to meet their current and future needs.

“Five-axis is our focus because that’s where the market’s going and because setup is reduced and unmanned operation is increased so much that up to four vertical machines can be pulled out when you put in one five-axis machine — plus, if you add an automation cell, you can pull eight machines out and still do more with less,” says Kauzlarich. “You can often reduce the number of operators you need monitoring each machine. At a time when companies are struggling to find skilled workers and stay competitive in a global market, that’s a big deal. It’s not about the number of machines you have, it’s about finding the right machines, and that starts by asking questions like ‘What’s your spindle utilization rate?’”

Kauzlarich says that most companies don’t know this and those that do are mostly down in the 50-60% range rather than in the 80+% range. If their utilization is low, they probably need to reevaluate their processes to determine how five-axis and automation might streamline their manufacturing operations. “These days, moldmakers can’t afford to make a mistake,” he continues. “They have to find the right machine for their current process and for where they want to go in the future.”

The Michons selected a five-axis YCM RX65 (UV 650 in other geographies) vertical mill with a trunnion table. They upgraded to a 60-tool magazine to ensure they had sufficient tools loaded to rough, finish and drill; selected a high-performance YCM 15,000-rpm spindle; added a chilled chip-flush coolant system to better control thermal growth; and they selected a FANUC controller since their other equipment uses that system.

The compact machine is designed for milling small-to-medium-size workpieces (max. 520 × 330 millimeters/20.5 × 13.0 inches and 300 kilograms/661 pounds) in hard metals as well as aluminum to maintain tight tolerances (to a few ten-thousandths of an inch) whether roughing or finish milling, and to perform under very demanding conditions. While the Michons’ original plan was to pull out one of their three-axis machines to make space for the new five-axis mill, the YCM’s compact footprint meant they could fit both machines in the space. Even better, they bought the machine at IMTS 2022, which meant they didn’t have to wait half a year to have a new machine built and shipped. It was installed last November.

“The thing that gives me joy in this business is not the purchase order but rather it’s helping transform a customer to make them faster, more efficient and more profitable thanks to equipment like the YCM RX 65.”

One Machine Does it All

The YCM RX65 has boosted Zero Tolerance’s productivity significantly. “On a standard block, we’ve now reduced our setups from six or seven to two, which is a huge time saving and increases our accuracy since we don’t have to flip a block four times just to put in a standard water system, and we don’t have to move it back and forth between multiple machines,” Steve explains. “Just in terms of the time it takes to square our blocks after heat treatment, we’ve reduced that step from three hours to 20 minutes and eliminated the need to grind the blocks afterward. Additionally, with five-axis capabilities, we can now cut geometry we’d previously have burned, which frees up more time we can sell on our EDM machines. Hence, the RX65 has increased our capacity in two ways.”

A recent job that Zero Tolerance ran on its YCM RX65 is a large gun magazine mold package involving 14 sets of cores/cavities in S7 steel hardened to 54-56 Rockwell. All squaring, drilling and roughing were done on the YCM. Photo Credit: Zero Tolerance LLC

A good example of what the machine can do is a large gun magazine mold package that Zero Tolerance won recently. It involved a three-tool package that makes three different parts and required machining 14 sets of cores/cavities in S7 steel hardened to 54-56 Rockwell. The tools featured undercuts, slides, sprue pullers and subgates. One set of cores/cavities has been finished and sent to the customer for qualification and the other 13 sets are at the roughing stage, waiting to be finished once customer approval is reached. Cavities will be diamond polished.

“We did all the squaring, drilling and roughing on all 28 blocks in just two and a half weeks,” Steve adds. “Just in terms of squaring our hardened blocks, we reduced production time from 80 hours to nine and still maintained an accuracy of 0.0002-inch [0.0051 millimeter], and that doesn’t count all the savings we’ll achieve in the other steps. We were also able to machine geometry we’d normally have EDM’d. In terms of setup reduction, the YCM enables us to make a mold 25% faster than we could before.”

“The thing that gives me joy in this business is not the purchase order but rather it’s helping transform a customer to make them faster, more efficient and more profitable thanks to equipment like the YCM RX65,” Kauzlarich adds. “Knowing we’ve helped make a company more globally competitive is really what it’s all about.”

Related Content

The Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

Read MorePrecision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

Read MoreHow to Generate the Ideal Tool Path for High-Level Accuracy and Finish

When a mold builder can’t compromise part accuracy and surface finish, CAM software with specialized programming strategies is essential.

Read MoreHow to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

Read MoreRead Next

New Michigan Technical Center for YCM Alliance

YCM Alliance held a grand opening of its new Technical Center in Sterling Heights, Michigan, last week, which is the first in a series of centers designed to showcase and demo machining solutions for die and mold machining, ultra-high-speed machining and general parts machining.

Read MoreSmall, Agile Mold Builder Keeps Speed and Accuracy at the Forefront

Michigan-based Zero Tolerance tests the limits of moldmaking and molding with teamwork and technology that permits changes on the fly.

Read MoreMMT Chats: 5 in 5 with Zero Tolerance

This special MMT Chat Series delivers five best practices in five minutes on ways to improve efficiencies. My guest today is Steve Michon, President of Zero Tolerance in Clinton Township, MI.This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=970;quality=90)