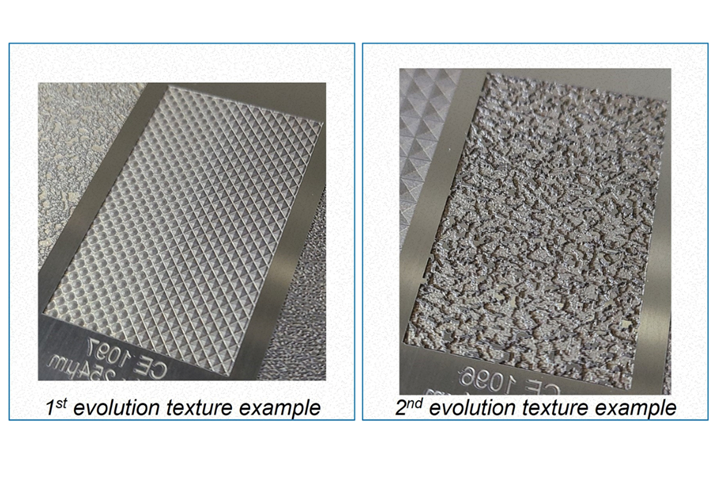

Cosmetic texture (left) and functional texture (right). Photo Credit, all images: Custom Etch Inc.

Laser texturing has opened the door to new possibilities in design, engineering and moldmaking with the development and implementation of five-axis laser machining.

The first evolution of laser technology focused on cosmetic texture applications that yielded unprecedented geometric and homogeneous patterns for products across the automotive, aerospace, consumer products, defense and medical industries. These engineered patterns demand full five-axis laser CNC machining as they are impossible to achieve with traditional chemical etching.

The second evolution involved the development and incorporation of functional textures. This application gives products a physical property while maintaining the cosmetic appearance required. For example, adding a gripping effect to ease handling for touch-or-grab products, or promoting a new surgical procedure to help bone growth on implants. Laser texturing has no limitation on design because it is a 100% digital process.

Digital watermarking.

That brings us to the new evolution — digital watermarking. This application places a unique digital code within a texture, completely hidden to the naked eye but fully readable by machine vision systems, including smartphones. This embedded digital watermark is applied directly into textures and creates an invisible code that is the size of a postage stamp. This process can only be done using laser technology.

Three Reasons to Use Digital Watermarking Textures

Here are three benefits of digital watermarking textures:

1. Brand Protection

- Counterfeiting impacts trade, jobs and brand reputation, making anti-counterfeit solutions attractive. For example, a laser digital watermark texture ensures product authenticity and aids in identifying knockoffs.

- A strategically placed digital texture offers digital tracking that can improve brand safety and anti-counterfeiting measures critical to regulatory compliance in the medical and pharmaceutical markets.

- Most products have no digital presence, making their lifecycle unknown. Laser digital watermarks confirm data effortlessly with digital authentication and analysis.

2. Recyclability

- Digital textures act as a digital passport for a circular economy and show consumers a company’s alignment with sustainability initiatives.

- Digital textures offer label-less design, making it easier to recycle.

- Digital textures are a solution for the regulatory scrutiny and consumer

sentiment that dictates manufacturers’ responsibilities to manage plastic waste better. For example, the packaging industry’s “Holy Grail 2.0” initiative, which involves more than 170 companies and organizations in Europe, focused on using digital watermarks to improve sorting accuracy.

With laser digital textures mold builders can offer customers new, innovative solutions and take advantage of new business opportunities.

- Digital textures deliver data about packaging attributes, such as reusable post-consumer recycled (PCR) material.

3. Traceability

- Digital textures play a vital role in Industry 4.0 by delivering product digitization that illuminates more about the manufacturing process and business. This digitally scanned data eliminates manual documentation and human error of vital product information. For example, tracking product transportation.

- Digital textures digitally structure and streamline regulatory compliance (FDA, OSHA, ISO, etc.).

- Digital watermarks identify the manufacturer, resin type, color, weight, use, recyclable versus non-recyclable, monolayer versus multi-layer packaging, carbon-black, opaque, difficult-to-recycle packages and new material introductions (PCR versus virgin).

- Unlike a static QR code, digital textures are dynamic and point to a new source of information at any given time — making them 100% customizable.

- Information via internal and external data retrieval means that product intelligence can be sent for deeper business insights on a product’s complete lifecycle, better brand integrity, accuracy, efficiency, security and supply chain traceability.

Laser texturing is widely accepted in today’s manufacturing process as it offers product improvement and higher quality. Laser digital textures give mold builders a new, innovative solution to meet customer needs and open the door to new business opportunities across all end markets.

Related Content

Four Micro Tooling Considerations

Issues involving gating, ejection, mold splits and direction of pull are of special concern when it comes to micro tooling.

Read More5 Hot Runner Tips for Moldmakers and Molders

Best practices for initial hot runner tryouts and effective preventive maintenance.

Read MoreLine Width vs. Depth Ratio in Laser Engraving

A laser does not produce 90-degree sidewalls. It requires a certain amount of draft in order to produce the required pattern.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreRead Next

How to Overcome Complex Mold Texturing Problems

Key benefits when considering laser technology for mold texturing and repair.

Read MoreThe Impact of Laser Technology Advancements on Moldmaking

A look at how improved laser technology benefits mold texturing, engraving and micromachining.

Read MoreTexturing Molds for Thermoplastics: Factors for Success

Factors to consider when selecting a texture or grain for a thermoplastic mold or die.

Read More