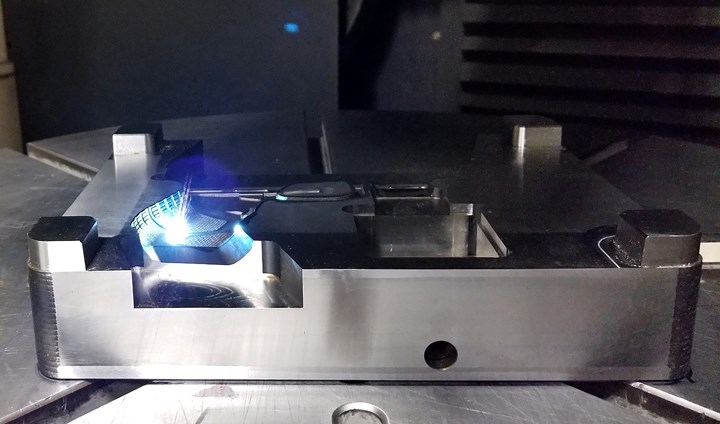

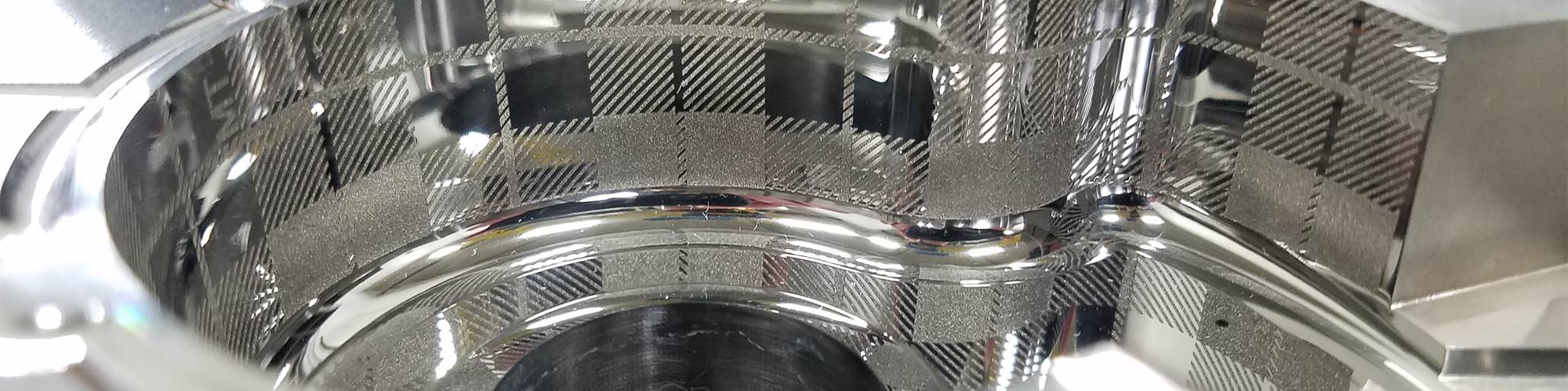

Laser texturing of a firearms mold in action. Photo Credit, all images: St. Paul Engraving

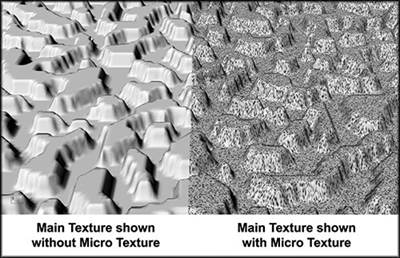

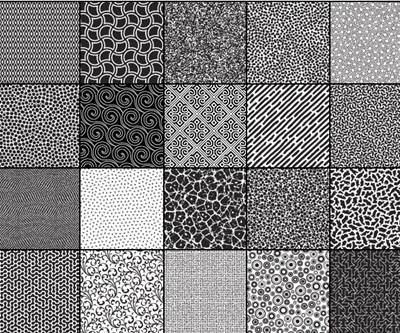

As moldmakers, it is essential to remain on the cutting edge of technology trends. One such advancement is five-axis laser technology for mold texturing, engraving and micromachining. Although this technology has been around for the last decade, there have been significant advancements in the last few years. Most notably is a Z focus shifter to reduce machining times, flexi-pulse sources to improve surface finishes and process automation to eliminate traditional labor-intensive techniques.

Laser Updates

The Z focus shifter, combined with a high-speed 3D scanning system, can reduce machining time by up to 40%, which is ideal when texturing high angles and complex geometries. This is possible because the Z focus of the beam changes to match the contour of the mold without the machine axis moving. Instead, mirrors adjust inside of the head to allow for a larger machining area within a defined deflection parameter. This reduces the required number of machine positions needed to complete a project while simultaneously increasing the patch size.

Patching without Z focus shifter (left) and patching with Z focus shifter (right).

The increased patch size or toolpath also helps to improve the surface finish. Without a Z focus shifter, you must blend multiple small patches when working with high-angle or complex geometries. However, with the Z focus shifter, you can complete complex, high-angle surfaces with fewer patches, producing higher quality, and more uniform textures while decreasing the machining time.

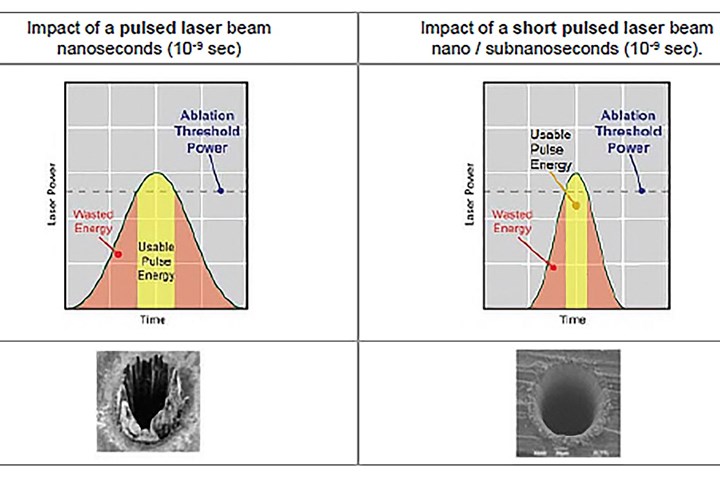

The Z focus shifter paired with dual flexi-pulse sources adds a new level of quality to laser texturing, engraving and micromachining. The flexi-pulse sources adjust the pulse duration from 4-200 nanoseconds. Reducing the length of the pulse improves quality by reducing the energy lost below the ablation threshold. This feature allows better control of the surface finish, minimizes burr or recast and reduces microfracturing. With dual sources, you can switch between 100 watts to 30 watts.

Moldmaking Impacts

In addition to reduced machining times and improved surface finishes, laser technology allows multiple processes, textures and engraving to be completed on one machine in one setup. For example, a firearms project requiring a custom print pattern on the grip with a matte finish on the frame and an engraved logo can all be completed on one machine. The ability to do this allows for unprecedented quality and turnaround time while delivering highly detailed, repeatable results that produce crisp lines with no undercut. At the same time, traditional techniques would require multiple steps, processes and/or machines to complete the same project.

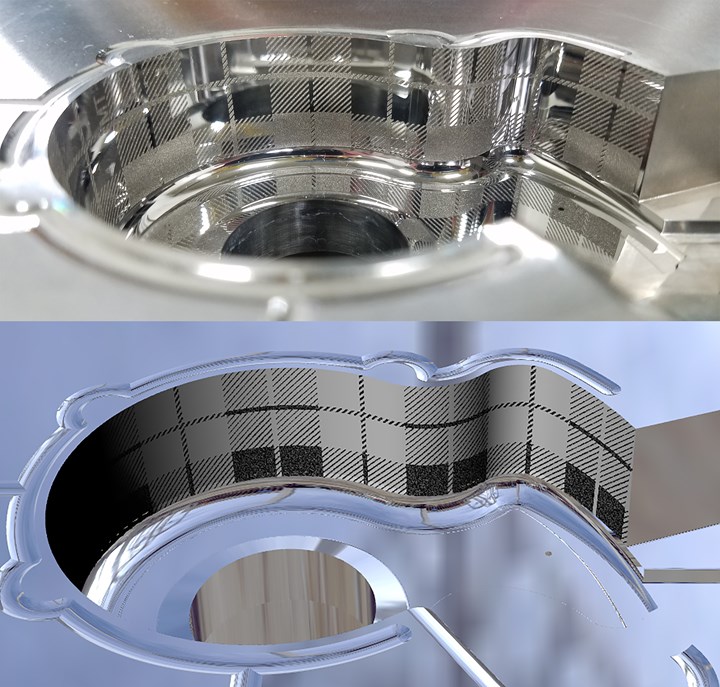

The steel of this mold component was laser engraved and machined to create the standing hexagon features and logo. Next, a custom print pattern was laser textured over the rest of the cavity.

Alternately, using chemical etching techniques involve labor-intensive masking and pattern placement via hand transferring and restricts etching of more than one pattern at a time.

The results are difficult to repeat and the process may produce uneven tape lines and undercuts with limitations to pattern designs and depths. In addition, acid etches downward to remove material and outward, which is problematic because it undercuts the pattern detail off as you etch down, creating sticking points around standing features that prevent proper ejection from the mold.

Laser technology unlocks the potential to achieve depths and detail not previously possible through chemical etching because laser ablation does not undercut detail like chemical etching does. The laser process is also highly repeatable, making it ideal for large, multi-cavity projects that require consistency. As an added benefit, since the laser process does not require acid etching or bead blasting, molds can be left partially assembled during the texturing and engraving process, which is ideal for molds with multiple inserts and ejector pins. This process reduces handling and production time while lowering the risk of damage to mold components through assembly/disassembly, acid etching and bead blasting.

Laser technology unlocks the potential to achieve depths and detail not previously possible through chemical etching because laser ablation does not undercut detail like chemical etching does.

The dimple of this mold cavity component for the automotive industry was laser micromachined to create a homogeneous distribution of light from one end throughout the part. This part highlights micromachining small dome details.

Conventional engraving and micromachining can also be a time-consuming process using multiple technologies. For example, pantographs have been used for decades to engrave directly into mold cavities or used to cut electrodes, then burned into the cavity using an EDM machine, and high-speed CNC machines can engrave into the mold cavity or cut electrodes. However, both options are limited concerning cutter sharpness, breakage and five-axis capabilities on small, detailed features in restrictive areas where cutter heads or EDM machines cannot reach.

Laser technology solves some of these issues. For example, with a beam width of 0.0013 to 0.002 inch, engraving small details is not a problem and the five-axis capabilities of lasers ensure access to any surface. In addition, with a focal of up to 11 inches and the ability to cut at angles, you can reach virtually any sidewall or pocket. In most cases, this eliminates the need to cut electrodes, burn engraving on hard-to-reach surfaces or achieve fine detail, as well as many issues associated with cutters such as sharpness, breakage, radii and cutter marks that need polishing.

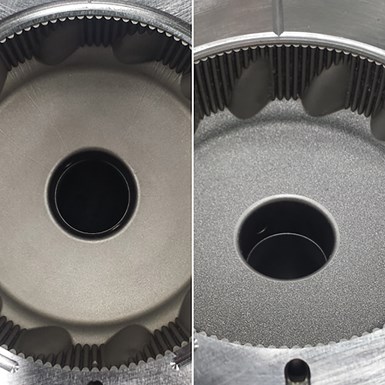

A cavity with an EDM finish (left) and then with a laser matte finish (right). Laser texturing directly over the EDM finish saves time and avoids the need to polish out the EDM, which is a necessary step with a conventional chemical etch process.

If laser engraving directly into the cavity is unachievable (e.g., to create standing text), laser engraving electrodes is the most economical option, as it can easily engrave sharp corners and apply small, intricate details on complex surfaces and geometries. In most cases, you can laser over EDM, which reduces polishing costs and speeds turnaround time. This is impossible with chemical etching techniques, since EDM is not affected by acid and must be removed before texturing. In addition, laser texturing, engraving and micromachining are less susceptible to weld and steel hardness which can cause multiple problems when chemical etching or repairing molds because the acid reacts differently to various hardnesses and materials.

Laser technology unlocks nearly limitless design capabilities including 3D and pattern morphing. These hexagons were laser engraved with an organic “leaf” textured in between. The leaf was 3D scanned to create the pattern.

Overall, laser technology, combined with process automation, puts the moldmaking industry one step closer to replacing traditional, labor-intensive techniques.

Related Content

Think Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.

Read More5 Hot Runner Tips for Moldmakers and Molders

Best practices for initial hot runner tryouts and effective preventive maintenance.

Read MoreHow to Achieve the Best Mold Finish

A look at factors that impact the polishability of tool steels and recommendations for obtaining a high-gloss finish.

Read MoreRead Next

Understanding Texture Repair

Developing a texture repair plan will help get a damaged mold up and running.

Read MoreA Look at Mold Texturing

Laser texturing, if understood and appreciated, can open up the door to endless possibilities in texturing, according to this texture house.

Read MoreHigher-Level Laser Mold Texturing

Eroded, sandblasted and chemically-etched mold textures are now 100-percent lasered at this Germany-based service provider.

Read More

.jpg;maxWidth=150;quality=70)

.jpg;maxWidth=400;quality=70)