Mold Steel Composition Streamlines Moldmaking Process

A mold material’s performance characteristics, like uniform hardness and dimensional stability, enabled Dramco Tool Co. Inc. to build a compression mold faster and more economically.

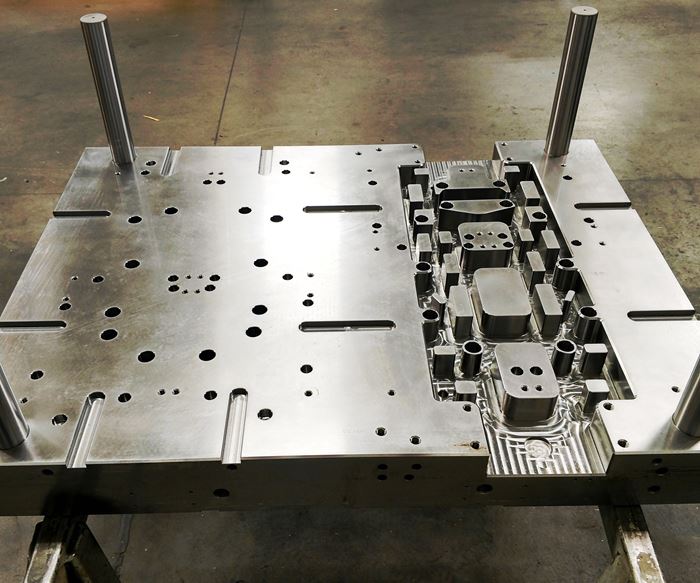

When Dramco Tool Co. Inc. (Grand Island, Nebraska) was tasked with building a compression mold for an aerospace customer that would run carbon-fiber reinforced epoxy SMC, the company knew that dimensional stability in the mold material would be critical. Dramco Tool Co. chose to build the tool with NAK-55, a pre-hardened mold steel that International Mold Steel Inc. (Florence, Kentucky) offers.

“We knew from experience that there are inherent problems with using a softer steel like P20 for this type of compression molding application,” Dramco President Larry Patten says. This tool was for an airframe part and measured about 40 inches long by eight inches wide and six inches deep, he says. The customer required Dramco to hold surface tolerances to 0.003 inch in several places down the length of the mold. “We needed to use a hard-enough material to hold up to the amount of production that the customer required over the life of the tool (which the customer specified as a 10-year program of full production), but we did not want to spend a lot of time on the front end of the tool build by going all the way to the hardened tool steels like H13 if we did not have to. NAK-55 fit the bill.”

Dimensional Stability Saves Time and Money

Patten explains that Dramco manufactured this mold for about $110,000 using NAK-55. If Dramco had built the mold using hardened tool steels, the price would have easily cost about 20 percent more. It also would have required at least three more weeks to complete. “If we built the tool out of H13, for example, many more steps would have been required using wire and sinker EDM because H13 is a harder material to machine,” he says. “Keeping in mind that this part is 47 inches long, we would have have been required to rough it out, leaving at least 0.10 inch of extra material because we know when it goes through the heat-treat cycle it will move, or warp, and we would have been required to machine that off in its hardened state.

“Alternatively, if we built the the tool using P20, rough machining would release a lot of stress that was already in the workpiece, but it would also introduce some stress,” he says. “When the machinist loosens the clamps after roughing, he or she might find that the part has a 0.03-inch bow to it, making it necessary to heat-treat it to remove any residual stress before re-machining it to make it straight again. With NAK-55, the machinist machines it, and it is complete. It's a stable tool steel that does not move when large amounts of the cavity are removed because it comes from the mill with no stress in it. All of the extra steps are not needed.”

Paul Britton, president of International Mold Steel, says, “When machining steel (hard spots or soft spots), the machinist releases the stresses and the steel moves. The degree to which it moves depends on what type of steel the machinist is using. In this type of application, whether it is P20 or H13, Dramco must do some sort of thermal cycle through the machining process. Dramco does not have that part of the equation with NAK-55. That is why a lot of companies use it when they must maintain tight tolerances, especially on long parts.”

Britton explains that it begins back at the mill. NAK-55 is manufactured using a double-melt or vacuum-arc re-melt (VAR) process. In other words, where P20 is a quench-and-tempered steel and H13 goes through a quench-and-temper cycle, NAK-55 is age-hardened, sitting at 950°F for a specific number of hours so there is no stress as is typical in quenched and tempered steels, only uniform hardness.

Uniform Hardness Improves Wear Properties

In addition to eliminating stresses and providing better stability, choosing NAK-55 over hardened tool steels also gave Dramco a more-uniform hardness to protect against wear from running abrasive materials in this mold. “The problem with running carbon-fiber reinforced epoxy SMC when we are compression molding is that we have to run at an elevated cure temperature, and the material contains up to 40 percent carbon-fiber reinforced glass, which is very abrasive,” Patten says. “Since NAK-55 has a 40-42 Rockwell hardness rating, we can machine it, and yet it is hard enough to hold up to the abrasion of running the tool.”

“[NAK-55] is a stable tool steel that doesn't move when large amounts of the cavity are removed because it comes from the mill with no stress in it. All of the extra steps are not needed.”

NAK-55 works very well with coatings for those who desire further surface protection, Britton says. The even distribution of NAK-55’s hardness allows for an effective substrate when coatings are applied given that the temperature does not exceed the age-hardening point of 950°F.

Patten says that NAK-55 conducts heat better than other tool steels, too.

“Thermal conductivity properties are probably more significant in injection molding, but they do benefit Dramco with this job in that NAK-55 produces a more evenly cured part more quickly,” Britton says. “All thermal conductivity is based on chemistry. The less alloy element that there is in the steel, the better thermal conductivity the machinist can achieve.”

For example, chrome has a high thermal-conductivity quotient, so the more chrome the mold material contains, the more the mold will retain heat during the processing cycle. NAK-55 has zero chrome in it. The material Dramco is molding must stay in the mold and cure at temperature, then cool outside of the mold. NAK-55’s better thermal conductivity allows more heat to be drawn out of the mold than is the case with other types of tool steels.

Material Provides Better Weldability and Surface Treatment

Patten says that NAK-55 is very weldable, and that weldability is especially beneficial when it comes to repairing a compression mold that will run for many years. “Any tool that runs for 10 years is going to need repair at some point,” he says. “Somebody's going to drop a bolt in there or crash it. Or in this case, with running a very abrasive SMC, there may be wear in critical areas that will need restoration. The benefit is that NAK-55 is one of the easiest mold materials to weld. In fact, the machinist can weld a cavity in NAK-55 and make it absolutely impossible to tell where that weld was, even under an optical polish.”

According to Britton, when a machinist welds NAK-55, the material softens. To restore its original base material properties, the machinist only has to re-age it at 950°F. “The weld and the base material are identical. The machinist will see no evidence of the weld on the part,” he says. By comparison, if the cavity is made from P20 and is welded, the heat-affected zone hardens. “Depending on the surface finish that the machinist is trying to achieve, a difference of even a couple of Rockwell points between the base material and the weld will show evidence of the weld on the molded part, so the machinist has to color match it or bring it down.”

Speaking of surface finishes, Patten notes that NAK-55 polishes better than P20. “We're taking these SMC tools up to a B2 finish using a 400 stone, which polishes very well up to that finish,” he says.

Britton concurs, saying, “It can go up to an A2 or A3, but NAK-55 does have sulfur in it, so the machinist has to be careful about that when polishing because sulfur-bearing steel will only have polishability to a certain level. That goes for all sulfur-bearing steels. Sulfur is basically dirt, but it aids in machinability, and what it gives in machinability it takes away in polishability.”

Extending Cutting-Tool Life

Another side benefit that Patten says he has noticed when machining NAK-55 is the cost savings that he has gained in cutting-tool usage. “It is difficult to produce hard numbers on that, but I would say that our tooling costs are on par with machining P20 and significantly less than machining H13,” he says. “P20 is about 30 HRC, and we do experience hard spots that can cause premature cutter wear, whereas we do not get any variance in hardness with NAK-55 because it is a very uniform steel, so tool life is extended. This is especially helpful in gundrilling operations.”

Britton says, “Anytime dimensional stability is critical to a project, NAK-55 is a nice option, whether for the type of application Dramco had for this aerospace customer or in others like injection molds, blow molds, injection blow molds and so on.”

“We have been building this type of mold since 2000, and NAK-55 has always been in our back pocket,” Patten says. “Stability matters, even in a 12-inch part. We can't pigeonhole NAK-55 for use only with long pieces. I can get stresses that make a 12-inch part move when I do not want it to, and I need to protect for it. We use NAK-55 for small inserts. It is just another tool in our arsenal to use specifically when we need a good, pre-hardened material that is well above 40 Rockwell and is stable.”

Related Content

VIDEO: AM Powder Addresses Current Inefficiencies, Sustainability and Skills Gap

Steel supplier discusses high thermal conductivity metal powders that also address the skills gaps via user-friendly materials and promote sustainability via durability and higher cycle counts.

Read MoreHow to Achieve the Best Mold Finish

A look at factors that impact the polishability of tool steels and recommendations for obtaining a high-gloss finish.

Read MoreVIDEO: Innovative Materials Boost Mold Efficiency

Advancements in metal 3D printing and stainless steel optimize mold building for diverse, high-demand industries.

Read MoreHow to Lower Cycle Times With the Right Tool Steel

Combining excellent mechanical properties, high wear resistance and high thermal conductivity in a specialty tool steel yields cycle time reduction.

Read MoreRead Next

Determination and Skill Save Critical Micro-Mold Cavity

Team 1 Plastics Inc. found a new supplier “soul mate” in Alliance Specialties and Laser Sales (Wauconda, Illinois), which displayed a commitment to, and the skills for, a successful micro-mold cavity repair solution.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More