StackTeck Systems Ltd.: Continuous Improvement Trims Leadtimes

This moldmaker’s maturing outlook on operations processing and scheduling, combined with continuous improvement initiatives, results in overall leadtime improvement of 15 percent and garners them the MoldMaking Technology 2008 Leadtime Leader Honorable Mention: Large Shop.

Like its name suggests, StackTeck Systems (Brampton, ON) has realized great success with its specialty on designing and building intricate stack molds—many with more than 100 cavities. But some may be surprised to learn that about half of StackTeck’s business is single face molds for the caps and closures, thinwall packaging, medical and personal care industries. The company is one of the largest manufacturers of plastic injection molds in North America as well as the largest producer in its market segment with a market share of approximately 70 percent in high productivity, four-level stack molds, notes StackTeck General Sales Manager Jordan Robertson. Additionally, the company offers injection molds (prototype, pilot, production and refurbishments), system integration services, and engineering services including plastic part design, flow modeling and FEA.

Since the company was named a Leadtime Leader Honorable Mention three years ago, the number of employees has been constant at approximately 200 employees, while output of this business has grown significantly. Sales have grown impressively by 76 percent from $23.9 million in 2001 to $42.1 million in 2007.

Coming Together

StackTeck was formed in 1998 to bring together advanced plastic injection moldmaking companies, with a focus on advanced manufacturing techniques, innovative product designs, and dedicated customer service facilities. Based on the leadership established by the original companies listed below, StackTeck remains the leader in these market segments.

- Tradesco Mold Limited (founded in 1976): Specialists in high volume molds including multi-level stack molds for high speed thin-wall applications.

- Unique Moulds (founded in 1969): Specialists in high cavitation molds for caps and closures, including medical and pharmaceutical applications.

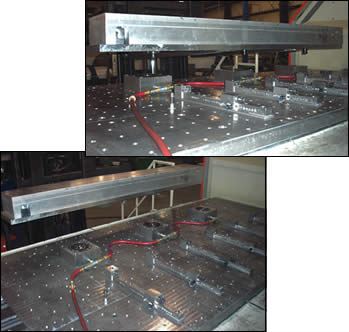

Within the industry segments in which StackTeck competes, it is typically the largest player and offers innovative technologies that provide molders of plastic parts the best possible productivity and piece part cost. As the fragmented moldmaking sector continues to consolidate, a key challenge is to maintain competitive delivery leadtimes while managing growing business volumes. In core businesses, StackTeck has reduced leadtimes significantly to nine to 11 weeks by automating the mold design process. The range of applications for which automated design is used, has been expanded significantly over the last year for standard container, lid, and cap molds up to 16 cavities.

Lean Strategies

StackTeck uses a combination of the following processes, technologies and equipment to maintain its tight leadtimes:

• Continuous improvement initiatives

Lights-out machining

Project review meetings of jobs with all functional areas present; focused on process time reduction, with subsequent Kaizen

• Concurrent engineering and manufacturing on critical chain activities

Ability to release partially engineered components to the floor, to start machining, while the final design is being done in parallel

• Automated engineering

• Leveraging innovation in CAD/CAM

Single integrated CAD/CAM system with associative updates

Visibility of data by all engineering and manufacturing personnel

Use of CAD 3-D viewers on manufacturing floor

StackTeck notes that these techniques have resulted in a 15 percent improvement in leadtime (since the last award in 2005) and an average on-time performance of more than 90 percent—with 60 percent of its molds delivered before the quoted due date. The 15 percent overall leadtime improvement is attributed to the aforementioned continuous improvement initiatives, in conjunction with the company’s maturing outlook on operations processing and scheduling. Key milestones are used for every project, with estimated durations set out at the kick-off. This scheduling system is available real-time, online, for customers who wish to see the project status. Other key factors in the last three years include: improved material control, improved scheduling visibility, strategic investments to resolve key business constraints (like high speed milling), and a new prototyping manager dedicated to the prototyping process.

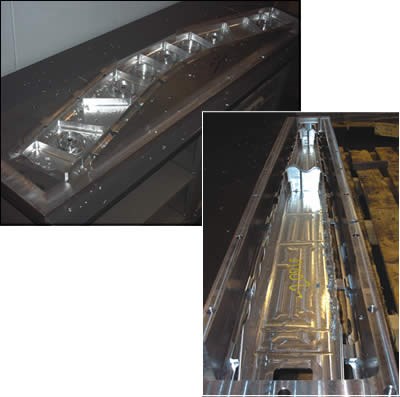

A Patented Success

One of the things that sets StackTeck apart is how the employees have contributed to the company’s success. “The capacity and sophistication of our engineering and manufacturing groups is unparalleled in our market niches,” Robertson emphasizes. “We have been able to introduce new technologies to the industry, frequently with patent protection. Employee ideas have turned into a large number of patented technologies—including those that enabled the first four-level stack mold, different mold unscrewing technologies, and compact mold designs to maximize cavitation. Currently, we are actively working with several companies on a revolutionary new cooling technology that we call Super CoolTM.”

International Challenges

To deal with today’s global competition, StackTeck has the following plan in place:

- Continuing to improve leadtime, speed to market and quality measures

- Leadership in developing new technologies which deliver higher productivity solutions

- Putting a high degree of focus on large, global multi-mold programs

- Assessing global supply chain capabilities overseas

- Eliminating waste in the business process

StackTeck’s plans for the future included continued growth, with only moderate resource increases, such as manpower and machining centers. A key area to support this growth will be the StackTeck Technical Services Center, where the number of molding bays has been expanded recently from 10 to 12, and the number of test machines will grow from eight to 10 during the first half of 2008.

Related Content

MMT's Most-Viewed March Content: Digitalization in Tooling, The Leadtime Leader Awards & More

March was a big month for MoldMaking Technology. Not only did we celebrate our 25th Anniversary, PTXPO, and announced the return of the Leadtime Leader award, we also continued to cover some of your favorite topics. Take a look at what you might have missed in March.

Read MoreLeadtime Leader Award Winners: Hall of Fame

MoldMaking Technology’s Leadtime Leader Competition has been an ongoing award since 2003. It is a prestigious award given only to North American mold builders that go above and beyond in moldmaking. Honorees have expressed the value the Award has afforded them in exposure, recognition, morale and new business. Isn’t it time we add your shop’s name to the list?

Read MoreMoldMaking Technology's Most-Viewed Content of 2024

The most popular MoldMaking Technology content according to analytics reports over the past year.

Read More2024 Moldmaking Insights: A Year in Review Part 1

A look back at the top moldmaking trends of 2024, as revealed through MMT's analytics. This review highlights the most popular technical articles, case studies, tips and best practices that captured the industry's attention over the past year.

Read MoreRead Next

StackTeck: Lean Strategies Combine for Niche Molds in Record Time

This one-stop shop powerhouse goes lean—cutting leadtimes nearly in half and earning MoldMaking Technology's 2005 Leadtime Leader: Large Shop Honorable Mention.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More