Triangle Tool is located on the north side of Milwaukee. Photo Credit, all images: Triangle Tool LLC

Provide a general biography of Triangle Tool.

David Olson, president, Triangle Tool: Triangle Tool has provided solutions for the plastic injection molding industry since 1963. We are proud to be celebrating our 60th year in business and even more proud of the partnerships we have developed over that time.

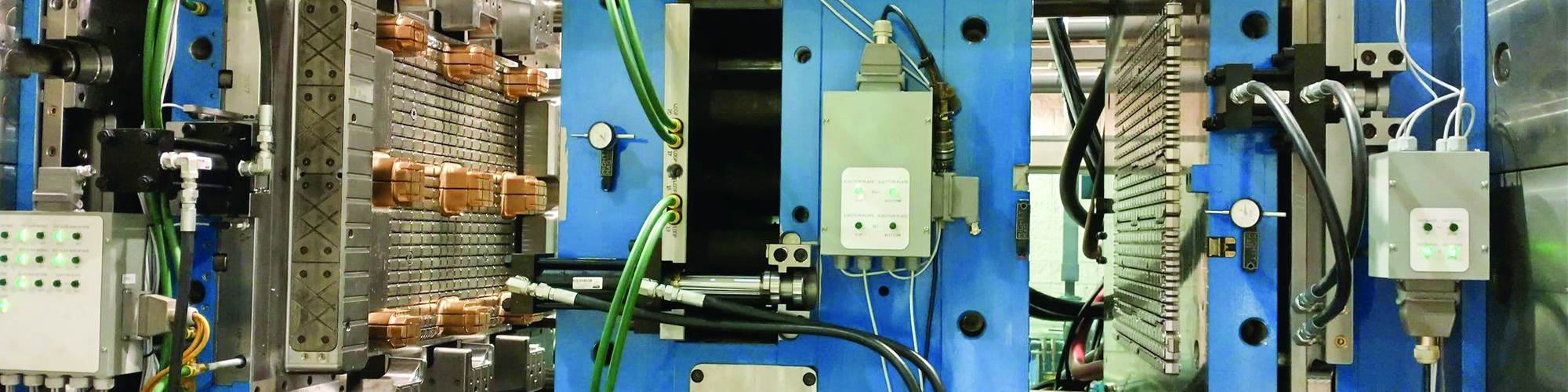

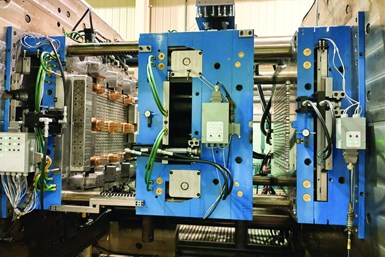

We focus on engineering plastic injection molds for various industries, including pallets, industrial containers, packaging, appliance, food service, home products, and lawn and garden, to name a few. Our press sizes — single- and multi-barrel machines — range from 800 to 4,400 tons, allowing us to sample every mold and provide customers with a turnkey mold building experience. Our sweet spot is high complexity and large molds; however, we do a variety of tools, including small part/high cavitation, modular stack frames, etc.

In 2021, Triangle Tool was purchased by The Purcell Companies (TPC), a long-term private company investment platform that employs more than 650 people across six companies and generates $140 million in annual revenue. TPC is focused on elevating Triangle Tool’s capabilities with investment in its people and facilities.

Triangle Tool is one of four manufacturing facilities that TPC now owns and is the largest of the group at about $40 million in sales this year. This acquisition has enabled us to invest more in the building, equipment and people. We continually upgrade our 215,000-square-foot facility on Milwaukee’s Northside with the latest technology and optimal working conditions for our 140 employees.

Over the two years since the acquisition, employees are seeing a much better place because the commitments have become a reality — tools being added, equipment being purchased, people being placed in key positions, facility improvements, etc.

What are Triangle Tool’s chief competitive advantages?

Olson: Our quality, delivery and service set us apart. Plus, we are focused on diversification to facilitate future growth and manage the ups and downs of business cycles. We are one company with three specialties: injection moldmaking, fluid end machining and specialty machining.

These capabilities all start with our engineering expertise. For example, we work with our customers early in a project — as early as preliminary part design. The partnership continues with our highly skilled machinists and moldmakers constructing high-quality injection molds. Then our experienced processing technicians sample and verify the mold before it’s delivered to the customer’s facility. Our service does not end there. We continue to provide outstanding customer service for the life of the mold.

We measure ourselves against industry best practices. We’ve aligned ourselves to be best-in-class in every segment. When people think of Triangle, they think of molds that require good engineering. Nobody fixes Triangle Tools. We fix everyone else’s. It starts with engineering knowledge. We try to find that blend where quality and expertise meet. We just finished fixing five of our competitor’s molds, which are running successfully.

Over the two years since the acquisition, employees are seeing a much better place because the commitments have become a reality — tools being added, equipment being purchased, people being placed in key positions, facility improvements.

How has the company mission changed since the acquisition?

Olson: The vision of the previous owner, Roy Luther, was to keep growing and he did so through multiple expansions. With an additional 11 acres, we have room to continue to grow. So, growth is the vision. We are the same company, but with our eyes on improvement in everything we do, we’re a better company overall.

What is the most impactful change to the business?

Olson: The structure was siloed in the past. Now we are team-focused. Today, our company has experienced, passionate people in strategically placed positions leading their respective teams. We function as a team and make decisions as a team. We are not a one-man show. No more top-down management. We are one Triangle. It’s amazing what you can get done when you don’t care who gets the credit. In the future, we want to continue improving our processes and diversify our customer base.

What is the most significant, recent change in your use of technology?

Olson: The most recent acquisition is our Grob 550 five-axis machining center with an automatic pallet changer. It has a horizontal spindle that guarantees the best milling technology and extremely stable and precise cutting of all materials. With a robot, we can have 10 different workpieces set up at 8 a.m. and then when we walk in at 8 a.m. the next day, all 10 pieces are done. Triangle and its customers/partners will benefit from this most recent investment’s process reliability, efficiency and durability. We also implement an automated scheduling system to improve efficiency throughout every project phase.

Triangle Tool’s latest acquisition to automate and accelerate its mold-building process is a Grob 550 five-axis machining center with a PSS-R900 automatic pallet changer.

Does your company have a difficult time finding and attracting new employees? Tell us how you are, or are not, addressing the skills gap in the industry.

Olson: We continue to leverage our reputation, working conditions and friendly environment to attract knowledgeable and highly motivated individuals to join our team. In addition, we continue to work with local high schools and technical colleges to develop younger talent and educate them on the exciting opportunities in our industry. However, Triangle still faces the challenge of employee shortages and continues to search for skilled workers. Today, seven active apprentices are on the floor learning the skills needed to build our high-quality complex injection molds.

Describe the most interesting mold project your company was awarded.

Olson: Not one mold or project stands out to Triangle Tool. If the project is important to our partners, it is equally important to us. The most interesting and notable projects to Triangle Tool are when we receive feedback that the mold is not only producing the intended parts, but has improved efficiencies for our partners.

Another challenge is speed. We build molds faster than our competition but must get even faster.

What is the shop’s toughest challenge?

Olson: We have many processes that we need to automate so we can do more things with fewer people. Our biggest challenge is automation because the equipment is very expensive.

The direction of our automation strategy is to use more machine time, so we are focused on improving scheduling to help us better understand where we are wasting time. We are in stage one of a new monitoring scheduling system that monitors the machines regarding runtime — speeds, feeds and programs. Then as the operator runs the programs, it tells the user where that block should go next.

Another challenge is speed. We build molds faster than our competition but must get even faster. What will set us apart is building the same quality tools faster than the competition. The key is automation and increasing the speed of design and programming. We’re trying to figure out what Siemens thinks is the optimal way for us to do a job, then we compare that to what we do currently and develop a hybrid design to get it out the door the fastest.

Triangle Tool is ISO 9001-certified and ITAR-registered. focusing on quality, delivery and overall customer satisfaction.

Customer service is more than speed. How do you work with customers different from your competition?

Olson: Our number one challenge with customers is getting the ball rolling on projects. Collaboration is more than just listening. It’s a hearing exercise. Communication and collaboration between sales and engineering are key to pushing jobs through the process.

We had a customer who recently came to us with a complex project and a desire to drive cycle time down. We delivered almost 50% cycle time savings. It comes with a price and a commitment from us and the customer to not skimp on anything. We do not settle!

What’s next for Triangle Tool?

Olson: Stay tuned. We are beginning to determine where we can find new business in new markets. We will not rest on our laurels.

Related Content

Combining Innovation and Artistry to Build Complex, Precision, Multi-Cavity Molds

This Florida mold builder is about high-performance, high-precision moldmaking by blending craftsmanship with technology.

Read MoreIndiana Mold Builder Decatur Mold Offers a History of Grit and a Future of Innovation

Decatur Mold Tool and Engineering Inc. serves as a tooling tour guide, helping busy tooling managers reduce uncertainty, lighten workload.

Read MoreOpenness to New Manufacturing Techniques Gives Mayer Tool & Engineering a Competitive Edge

This Michigan mold builder adapts, problem solves, brainstorms and collaborates to exceed customer expectations.

Read MoreNextGen Mold Technologies is Sticking to the Plan

I caught up with Dennis Goggin, president of NextGen Mold Technologies, to learn how much has changed for this startup mold builder since we last connected.

Read MoreRead Next

Cross Training, In-House Capabilities and Collaborative Design Move Helm Tool Forward

Cross-training, bringing it all in-house, molding and collaborative design are essential to Helm Tool's success.

Read MoreSpecialist Automotive Mold Builder Mentors in Work and Life Skills

Southeastern mold builder PFAFF Molds sets the standard in toolmaking for automotive window and vehicle body sealing systems through knowledge-sharing and automation.

Read MorePennsylvania Mold Builder Doubles Footprint, Maintains Quality and Company Values

Quality Mold Inc. doubles its manufacturing footprint but maintains its private company values and structure, delivering quality and fast turnaround from mold design and build through sampling.

Read More