CNC Grinders Decrease Manpower, Improve Delivery Times

Switching from manual to CNC grinders results in leadtime, programming, accuracy and tolerance benefits for this moldmaker.

Prestige Mold, Inc. (Rancho Cucamonga, CA)—a designer and manufacturer specializing in multi-cavity, multi-component, hot runner, interchangeable molds primarily for the medical and industrial markets—prides itself on being an industry leader among plastic injection mold manufacturers by providing the best service, best quality, and superior mold design and manufacture. The company is committed to implementing and utilizing state-of-the-art mold manufacturing technology—including automation and robotics—to give its customers cavity-to-cavity repeatability for greater part consistency.

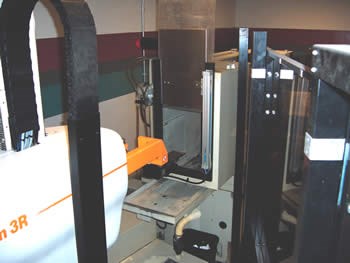

Over the past several years this moldmaker has faced shorter delivery dates coupled with tighter tolerances for the medical molds it builds. According to Shawn Pecore, CNC/Automation Specialist for Prestige Mold, the company has to hold .00005 to .0001 on most details. In order to meet these demands, the company purchased some higher-end, CNC equipment with 3R Work Master Robots to create cells that can run 24 hours a day. Okamoto Corp.’s (Buffalo Grove, IL) 8-20 DXNC CNC grinder (see Chart 1 below) allows Prestige Mold to perform lights-out grinding—which cannot be accomplished with a manual machine—allowing the company to meet its customers’ demands for due dates. “Having lights-out cutting is a must in today’s market,” Pecore notes. “If shops don’t start doing this, they will be dead in a couple of years.”

The Daily Grind

Prestige Mold uses Okamoto’s grinder to grind blocks of steel flat, square the blocks, and then grind all of the shutoff details in the cavity and core blocks, in addition to grinding electrodes with multiple details on each electrode. Accuracy benefits were immediately realized, Pecore states. “With the CNC grinder you can basically grind it, redress the wheel, come back and grind it again and you can do that in several steps to ensure that when it’s done grinding what it is grinding, it’s pretty much there,” he states. This, in turn, has reduced leadtimes.

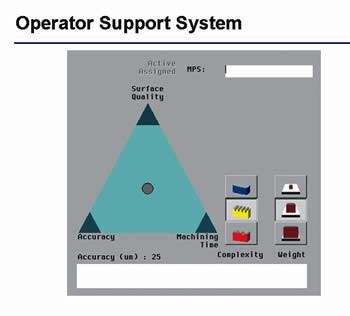

According to Victor Truelsen, a technical sales engineer for Okamoto, the DXNC machine uses a “double vee way” system, which allows for superior heat distribution, and is “machine ridged”—increasing the machine’s long-term accuracy. “The standard hydraulic temperature control system allows extended machine running time without any noticeable influence from heat expansion,” Truelsen explains. “And, the user-friendly conversational program system allows for simple touch-and-teach programming inputs with color graphical templates. This allows operators with no CNC experience to get complex wheel forming and grinding cycles by following the interactive programming system.”

On the shop floor, the machine has increased Prestige Mold’s lights-out capabilities. “This equipment is a pretty big investment,” Pecore notes, “so we need to get as many unmanned hours out of it to compensate for this. We used to have to run two shifts, which we no longer have to do. We now run one shift.”

Fortunately, the learning curve was pretty quick. “The guy I have running the equipment had no CNC experience and he learned it fairly easily,” Pecore says. “If anything, we are still learning how to use the machine to its fullest potential.”

Prestige Mold is so satisfied with the Okamoto grinder it just purchased another machine—the ACC 12-24 DXNC—a larger version of the current machine it is using. Okamoto’s Truelsen says this will expand Prestige Mold’s work envelope of their current grinding capabilities. “With the addition of the powered rotary dresser on their new machine the long-term accuracy of the dressing cycles will be greatly increased, improving on their current lights-out accuracy and wheel dressing capabilities while decreasing their cycle times,” Truelsen comments. Pecore likes the fact that the company can achieve double productivity by putting the additional machine on a 3R robot with still only one operator—increasing productivity without adding manpower.

| Chart 1 | ||

| Model |

8.20DXNC | 12.24DXNC |

| Grinding Capacity | 8” x 20” | 12” x 24” |

| Minimum Increment for Cross Axis | 0.00001” | 0.00001” |

| Minimum Increment for Vertical Axis | 0.00001” | 0.00001” |

| # of Simultaneously Controlled Axis | 2 axes | 2 axes |

| Maximum Table Movement (Manual) | 26” | 30” |

| Magnetic Chuck Size (W x L x H) | 8” x 20” x 3.2” | 12” x 24” x 3.2” |

| Table Load Capacity | 440 lbs | 925 lbs |

| Grinding Wheel Size (D x W x B) | 8” x 0.75” x 1.25” | 12” x 1.5” x 5” |

| Grinding Wheel Speed (60 Hz) | 3,600 rpm | 1,800 rpm |

| Equipment specifications. Chart courtesy of Okamoto Corp. | ||

Related Content

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreThree Good Reasons to Switch from Three- to Five-Axis Machining in Moldmaking

Five-axis machining technology is a great tool in the moldmaker toolbox.

Read MoreHow to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

Read MorePrecision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

Read MoreRead Next

Smart Machining: A New Development in High-Speed Machining

Improved process reliability, optimized machining performance and reliable unmanned operation are the results of smart machining implementation.

Read MoreDoubling and Quadrupling Machining Speed, Capacity and Output

Vertical machining centers help to achieve the rapid tool production time a medical thermoformer’s customers demand.

Read MorePart One of a Three-Part Series Five Steps for Improving Your Shop’s Maximum Productivity

Learn how to evaluate your shop’s productivity and begin increasing it by considering the variables of implementing hard milling and high-speed machining.

Read More