Mold and Die Suite Empowers Mold Manufacturing Operational Excellence

Specialized HxGN software suite includes Hexagon technologies like VISI, WORKCNC, NCSIMUL and others to support production of complex plastic injection molds, progressive dies, forming dies and other tools.

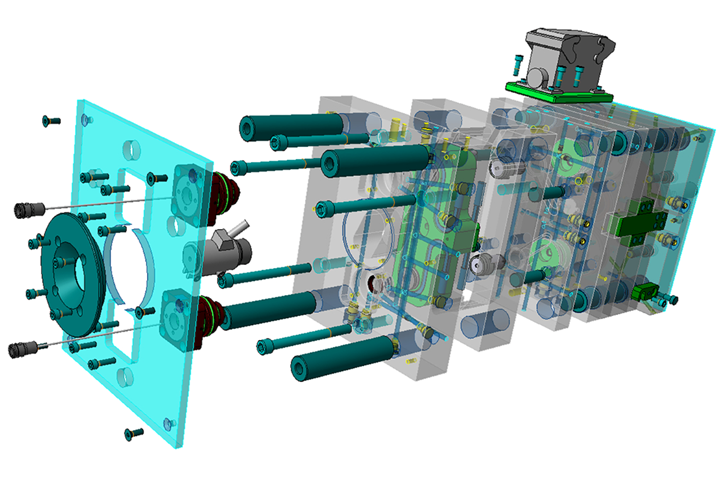

Hexagon’s Manufacturing Intelligence division has released HxGN Mould & Die, a suite of dedicated CAD/CAM, engineering and automation tools empowering mold and die and tool manufacturers to increase efficiency, reduce costs, and design and produce high-quality tools — plastic injection molds, progressive dies, forming dies and similar tools — for their customers across industries ranging from automotive to aerospace and beyond.

Suite capabilities include CAD/CAE for plastic injection mold design, CAD/CAE for progressive die design, CAD for manufacturing preparation, CAM for CNC machine tool programming, process simulation and G-code verification and optimization, shopfloor production intelligence, and automation and collaboration powered by Nexus, Hexagon’s digital reality platform. The company says the suite’s simulation tools help manufacturers understand the feasibility and cost of moldmaking processes with actionable information.

For plastic injection mold manufacturers, the suite provides tools for design and engineering, flow simulation, reverse engineering, automated electrode design and CNC machining. It builds upon Hexagon’s VISI and WORKNC software, providing comprehensive multi-axis CAM programming capabilities, direct modeling of solids and surfaces, and supports the construction, editing and repair of complex 3D geometry.

The suite also provides plastic flow analysis tools to help shopfloor teams produce cost-effective and reliable molds that will perform as required. Its simulation capabilities are simple to use, which ensures that non-engineers or less experienced employees achieve optimal results. The creation of intricate or difficult-to-machine injection mold features is further simplified with the automated design and simulation of EDM electrodes and their associated holders.

For progressive die manufacturers, HxGN Mould and Die offers a connected workflow with tools for design and engineering, simulation and production. It enables the step-by-step unfolding of surface and solid models, which gives designers more control over the development of each forming stage. Flexible strip layout capabilities and the ability to simulate the performance of the strip at any stage in the design process make it easy to quickly analyze the results of design changes. The software also helps manufacturers predict springback and offers compensation strategies when challenges with material performance are identified.

The suite also supports shops via advanced machine tools, using VISI and WORKNC software to help programmers optimize machining cycles and specialized cutting strategies specific to mold production.

Related Content

-

Three Good Reasons to Switch from Three- to Five-Axis Machining in Moldmaking

Five-axis machining technology is a great tool in the moldmaker toolbox.

-

Tolerancing in Mold Design, Part 2: Using GD&T to Address Conventional Tolerancing Issues

Mold designers can achieve a single interpretation of workpiece functionality when following the American Society of Mechanical Engineers Geometric Dimensioning and Tolerancing standard.

-

How to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.