For 50 years, Eifel Inc. has placed a strong emphasis on maintaining competitiveness and success by focusing on people, process and technology. Photo credit, all images: Eifel Inc.

Who is Eifel?

Richard “Rick” Hecker, president, Eifel Inc.: Celebrating 50 years in business, Eifel, founded in 1973 by my father, Josef Hecker, originated as a tooling aids provider for automotive suppliers. Being an immigrant from Germany, my dad leveraged his artisan craftsmanship and ability to build relations into 15 years of tooling support in the automotive and aircraft industries. This set the groundwork for the company. Initially a small shop named after his home region in southwest Germany, today Eifel boasts a staff of 16, including one apprentice and a throughput of 200 custom molds annually. All of this is in our Fraser, Michigan, location.

Facing challenges in the mid-1980s, I joined Eifel with a plan to incorporate advanced technology. We invested in CAD/CAM software and CNC machining centers and became known as a quick concept-to-completion moldmaker. By 2000, we rebranded the company to Eifel Inc., and shortly after I completed a buyout and took over as the CEO/owner.

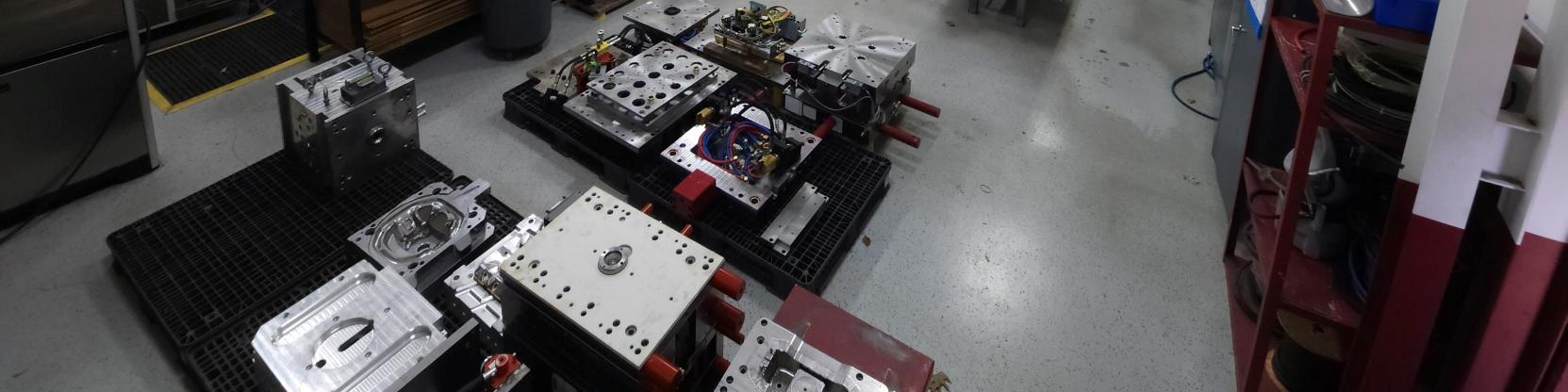

Eifel has evolved into a leading product development and production tool manufacturing service provider. We cater to prominent Tier 1 automotive customers. Our experience includes production molds, prototype tooling, two-shot, transfer two-shot overmolding, magnesium die casting and urethane molds.

Our niche is Class A parts, such as foam steering wheels, vehicle aftermarket parts, airbag housing units, car center consoles, headlamps and seat back panels. However, we also build plastic injection molds for home goods, construction, electronics and various recreational vehicles (RVs), including side-by-sides (SxS) and utility task vehicles (UTVs). Beyond tooling, we offer multistage, in-depth design reviews, feasibility consultation and professional contracting. We truly bring a full-service approach to every project.

What do you view as your chief competitive advantage?

Hecker: We place a strong emphasis on three crucial elements for maintaining competitiveness and success: People, Process and Technology, collectively referred to as the “PPT Approach to Program Management.” We prioritize a healthy work/family balance, fostering a dedicated work ethic among our longstanding employees and cultivating a positive can-do culture.

Regular reviews and improvements to our current processes are integral to sustaining effectiveness and exploring potential enhancements to our system. Our commitment to researching and adopting new technologies in machining, equipment and software reflects our ongoing efforts to improve efficiency.

Eifel Inc. has evolved into a leading product development and production tool manufacturing service provider, catering to Tier 1 automotive customers by providing production molds, prototype tooling, two-shot, transfer two-shot overmolding, magnesium die casting and urethane molds.

The key to our success lies in having the right people in the right positions throughout the entire process. We recognize our staff’s strengths and efficiencies and evaluate how to best use them throughout the product realization process. We draw from a wealth of experience and machining wisdom from seasoned machinists, which inspires a thirst for knowledge among their younger counterparts on the shop floor. It is exciting to observe the team problem-solve, discuss new methods and improve with each challenge.

Eifel has evolved into a leading product development and production tool manufacturing service provider.

Michael Nye, our general manager, brought with him an extensive knowledge base when he appeared on Eifel’s doorstep in 1999. A master communicator, he has the experience and diplomacy required to be an advocate for the customer while also being a leader directing tools through the design and manufacturing process.

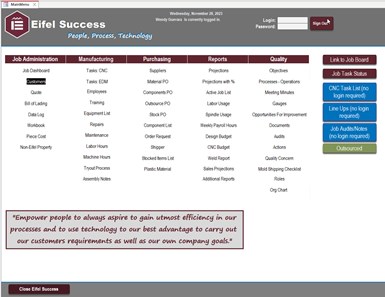

Eifel Success is Eifel Inc.’s custom ERP system that displays up-to-the-minute job costing and offers a place for the team to communicate about current jobs.

One of our advantages is our enterprise resource planning (ERP) system, Eifel Success. Our controller, Wendy Guevara, who also came to work at Eifel in 1999, began building a Microsoft Access database in 2003 to handle quoting and cost breakdowns, with insight from Michael Nye. By 2013, the system had evolved into a full-service ERP system, used to run all aspects of the business, including sales, purchasing, shipping/receiving and quality.

Eifel Success provides insight into the manufacturing process, displaying up-to-the-minute job costing and offering a place for the team to communicate about current jobs. This custom ERP system enables us to implement improvements and crucial system changes within the same day, depending on the complexity. You cannot do this with subscription-based software — with those, you must fit your business into a one-size-fits-all system. The custom system gives us so much more flexibility and freedom to review and improve our process continuously, and in addition to all that, we have 20 years of data history.

In our CNC department, we have just the right mix of experienced CNC machinists who have been in the trade for 30 or more years and machinists who we plucked right out of high school and educated here at Eifel. Both are instrumental in nurturing a culture of intellectual curiosity that serves employees of all experience levels. There is much to be learned from the years of experience that our mature machinists bring to the table, combined with the insight into new technologies that our younger generation possesses. About half of our CNC staff has been at Eifel for over 20 years and were here to witness the dawn of five-axis CNC machining at Eifel.

Our approach is likened to a three-legged stool, where the length of each leg is critical. If one leg is too long or too short, the stool falls. Similarly, in our project management approach, any shortfalls can disrupt the process and put our customers’ deadline in jeopardy. In the face of increasing demands for speed and shorter deliveries in mold building, adhering to our PPT approach to program management ensures a robust and resilient strategy.

What have been your most recent technology investments?

Recent acquisitions include a Hermle C650 HS Flex System with a six-pallet automation cell for 24/7 machine utilization.

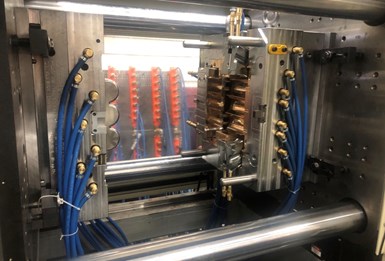

Hecker: Recent acquisitions include a Hermle C650 HS Flex System featuring six-pallet capacity automation cells, enabling 24/7 machine utilization through the pallet system and a Nissei 360-ton, high-performance electric injection molding machine.

For the past 50 years, Eifel has been working steadily toward a singular goal: “To be the quickest in delivering tooling from concept to completion.” This journey has led us to standardize our CNC setup procedures, using the latest technology in workholding. This ensures accuracy and repeatability, reduces setup times and improves the overall manufacturing lead time.

Our standardized approach involves knowing the precise location of the block on the table, and our approach to CNC machine setup is repeatable in each machining cell. We can move from machine to machine and be confident that the block, and more importantly, the detail on that block, is in the proper working envelope of the machining center. During the CNC planning phase, we tactically set up multiple workpieces, evaluate tooling strategies and load the toolchanger, execute the programs and let the machine run unattended. There are many moving parts to this step in the process and countless matters to consider. However, the theory behind it is our everyday reality — leveraging the PPT approach as a proficient guide.

A Nissei 360-ton, high-performance electric injection molding machine plays a vital role in reducing Eifel’s dependence on external services for mold trials and opens new opportunities in the molding space.

Our acquisition of the Nissei molding machine is a significant advantage. When our customers ask for a small-batch part run to evaluate the part prior to tool shipment, we often respond by performing that tryout on-site at Eifel. This allows our customers and our moldmakers to gain firsthand insights into mold dynamics, part processing and the impact of engineering changes.

Eifel’s expertise includes, but is not limited to, the following resins: TPO (thermoplastic polyolefins), PP (polypropylene), ABS (acrylonitrile butadiene styrene), 30-50% glass-filled nylon and TPE (thermoplastic elastomers).

Eifel is helping to lay the groundwork for highly skilled moldmakers before students reach high school by promoting moldmaking career opportunities.

How have you changed your approach to workforce development?

Hecker: We have put more effort into finding and developing new talent for our current and future workforce. Today, Maria (my wife) and I are invested in workforce development. We encourage our team members to expand their horizons within Eifel. In addition, Ann Sulkowski, our human resources manager and apprenticeship coordinator, works closely with the Michigan Department of Labor and Apprenticeship Training to ensure that we stay ahead in the industry and guarantee our apprentices receive comprehensive training to become proficient moldmakers and mold designers.

We recognize that the groundwork for highly skilled moldmakers must begin in high school or even earlier. The demand for young, eager-to-learn, skilled tradesman apprentices is high, so we must share our successes and promote these careers to young people who may not realize they are available.

I am involved with local high schools, vocational/technical schools and community colleges, showing students at all levels that there are rewarding career opportunities available in manufacturing, especially in mold manufacturing.

For example, we work closely with the CTE directors at Fraser High School to help students with co-op positions at Eifel, we provide machines and tooling in the classrooms at Lincoln High School and lead hands-on training sessions, and we partner with Macomb Community College to offer an apprenticeship program.

Talk about the third generation entering the business.

Rick Hecker and his son, Eric, are working together to grow Eifel Inc. Eric is currently a program manager gaining business management knowledge and researching ways to expand Eifel’s expertise into new markets.

Hecker: When considering succession planning, my father initiated the business 50 years ago, making it my responsibility to ensure the company’s success over the next five decades. From the beginning, we have identified ourselves as artisan craftsmen. Roughly 30 years after establishing Eifel Pattern and Model Co., we underwent a rebranding to Eifel Inc., introducing a subtle shift in focus.

While preserving our old-world attention to detail, we embraced progress with a new emphasis on CNC machining and CAD/CAM technologies. Concurrently, I assumed the roles of president and CEO, succeeding my father and completed the buyout of the business.

Fast forward to 2023, our 50th anniversary, and my son, Eric, has joined the company. He is acquiring expertise in moldmaking, sales, program management and molding. If he so desires and we mutually agree, he will eventually assume leadership of the company.

Our strategic plan is to ensure the Hecker name remains an enduring part of Eifel Inc. After all, our heritage is deeply embedded within these walls.

We place a strong emphasis on three crucial elements for maintaining competitiveness and success: People, Process and Technology, collectively referred to as the “PPT Approach to Program Management.”

How do you see Eifel evolving in the next few years?

Hecker: Eifel will continue to grow its customer base in new markets and expand revenue streams in five-axis machining and low-volume plastic injection molding. As a company, we cut our teeth primarily in the automotive space. Given our proximity to Detroit and the Big 3, it made sense. We are researching and reaching out to new markets in new regions outside of Detroit’s automotive sector. We have taken steps toward diversification into consumer goods. We believe that there are opportunities for us to support that space with high-quality American-made tooling.

Our second area of diversification involves venturing into the single-use medical device industry. We recognize our strengths and areas for needed growth to meet these markets, and we are actively implementing changes and training to ensure success as we move ahead.

My son, Eric, serves as one of our program managers. He has the unique perspective of growing up and working in the shop, so he understands manufacturing capabilities and limitations. He is currently gaining knowledge of business management while researching how to expand Eifel’s expertise into new markets. At the same time, Michael Nye is concentrating on existing customers to ensure seamless progress on their programs, foster communication and maintain relationships.

I play a crucial role in bridging the gap between new market development and sustaining our current partnerships, recognizing that this is a long-term process — we understand the importance of setting goals and milestones. As the saying goes, “Rome wasn’t built in a day.”

We are cultivating relationships with companies beyond the traditional moldmaking industry. Why? To prevent idle CNC machines. These collaborations provide opportunities to keep our spindles turning. Manufacturing opportunities outside of moldmaking can challenge our traditional machining approaches, offering opportunities for learning and improvement.

For example, the addition of our Hermle C-650 machining center increases our capacity, allowing us to set multiple workpieces on various pallets and run the machine 24/7. It is akin to adding two shifts of available five-axis CNC machining capacity, which translates to increased uptime and additional revenue streams in machining.

The Nissei molding machine also plays a vital role in reducing our dependence on external services for mold trials and demonstrates our willingness to undertake pre-shipment production runs. Having our own press opens new opportunities in the molding space. While we do not perceive ourselves as competitors to our contract molding customers, we do see opportunities to augment their offerings by providing genuine pre-shipment mold trials with extended production, ensuring the tooling is 100% ready to hit their machines and “run right out of the box.”

One of Eifel’s most challenging project involved three-, four- and five-stack plastic injection molds for a wine rack.

Describe the most interesting/notable mold project your company was awarded.

Hecker: It would have to be our three-, four- and five-stack plastic injection molds for a wine rack. This marked a new venture for Eifel as historically, we have been an automotive component tooling supplier, and these programs focused on consumer goods. This transition represented a departure from the conventional “hold the dimensions/hit the numbers” approach of automobile tooling to a more aesthetic type of tooling. While holding dimensions remained crucial, the appearance of the finished parts became equally critical, requiring different approaches to the mold’s design and construction.

The Eifel Inc. team had to use different approaches to the wine rack’s mold design and construction to hold crucial dimensions and yield the proper finished part appearance.

We are accustomed to incorporating split lines in tooling for sub-inserts, enabling the use of high thermal capacity alloys like AMPCO Bronze or MoldMax to help control the cycle by managing part and mold temperatures. However, for these molds, witness lines were unacceptable due to the aesthetic requirements of the product. Foreseeing hot spots from the processing temperature of the molding resin, we built the entire cavity from BeCu material. This presented a learning curve, as the material was not only expensive but also challenging to EDM and had different growth and contraction rates compared to surrounding steel, posing fitting challenges.

Secondly, we needed to polish the entire tool — cavity, core and slides (with three slides per part) — to an A2 finish, a departure from our usual B2 or B1 finish. This near-optic finish was necessary because no one wants to see scratches in an otherwise clear PET part.

Third, although we have experience building hot runner tooling, these molds required valve gating to minimize vestiges around the gate. Processing knowledge and thermal expansion played a crucial role here. The customer selected a PET copolymer for this product, requiring the injection of a resin in the range of 580°F into a mold at 55-65°F to achieve clarity in the molded parts. Talk about thermal shock — well, this is it! But it was necessary because if you allow PET to cool slowly, it turns a milky white. Rapidly freezing PET on a cold mold surface was essential.

The choice of BeCu and considerations for thermal expansion in the hot runner and gates added complexity. Balancing the fitting and assembly of the mold in the cold state while ensuring alignment from the hot runner at 580°F to a mold insert at 60°F presented a mathematical challenge.

While we did encounter some hiccups that required a trip for field repairs and an in-depth preventative maintenance/hot runner modification, the overall experience was a valuable learning opportunity. We now have this knowledge and are prepared to tackle other challenging projects.

Related Content

Predictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

Read MoreHow to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MoreTackling a Mold Designer Shortage

Survey findings reveal a shortage of skilled mold designers and engineers in the moldmaking community, calling for intervention through educational programs and exploration of training alternatives while seeking input from those who have addressed the issue successfully.

Read MoreEditorial Guidelines: Editorial Advisory Board

The Editorial Advisory Board of MoldMaking Technology is made up of authorities with expertise within their respective business, industry, technology and profession. Their role is to advise on timely issues, trends, advances in the field, offer editorial thought and direction, review and comment on specific articles and generally act as a sounding board and a conscience for the publication.

Read MoreRead Next

MMT Chats: Molds, Molding, Marketing and Membership

MoldMaking Technology Editorial Director Christina Fuges chats with Eric Hecker, Sales and Project Engineer for Eifel about his focus on sales and marketing, the move into molding, technology and training trends and his mission to help increase membership in Mold Technologies Division of SPE. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreEifel Mold & Engineering Celebrates 50 years in Moldmaking

Under the leadership of founder Josef Hecker and his son, Rick Hecker, Eifel has developed a reputation for producing high-quality injection molds, in addition to playing an active role in giving back to the industry.

Read MoreThree Keys to Success at Eifel Mold & Engineering

For every decision, this toolmaker makes a point to consider the potential impact on three interrelated considerations: people, process and technology.

Read More

.jpg;maxWidth=300;quality=90)