Visual Search Application Instantly Locates Data Needs

VizSeek visual search technology enables users to avoid spending hours hunting through databases to locate drawings, or duplicate already-existing work when quoting or manufacturing injection molds.

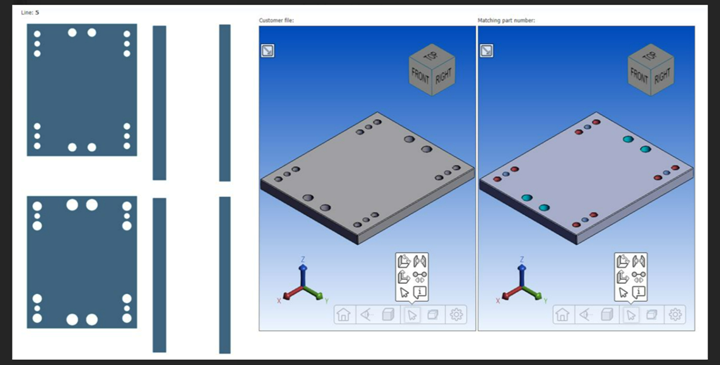

Professionals in all phases of the injection molding process face a dilemma: The creation of a drawing. VizSeek visual search is an alternative software that enables manufacturers to use a file containing the desired shape — whether a photo, 2D drawing, 3D model, pdf or even a hand sketch — and drag and drop that into a search box, instantly locating every file in one’s database containing that shape. Users can then refine the results using text and shape search until the needed drawing is found, reportedly reducing the search time from hours to seconds. Examples of these features are shown via two injection molding applications in the video below.

According to the company, this solution and AI-powered text search has the potential to save manufacturers thousands, sometimes tens of thousands, of work hours annually, increasing profits and productivity.

One primary application is quoting. As the quoting engineer opens the email to examine the request, the VizSeek visual search technology extracts the shapes in the attached files and pulls up anything in the database containing those shapes. The quoting engineer can immediately identify if the company has already made the needed part, or something very close, allowing the engineer to start from existing work. If the part is an exact match, VizSeek ensures avoidance of duplicated work. Moreover, if the part is close, the engineer can start from existing work — whether it was a successful quote or not — easily modifying the existing drawing and using critical data from the previous quote to quickly return an accurate quote.

Related Content

-

What Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

-

Products and Services for Multiple Moldmaking Needs

New year, new technology roundup! Featured here is a collection of product offerings, from profile milling cutters to industry-specific CAD/CAM software to innovative hot work tool steels.

-

VIDEO: Perspective on A.I. and Mold Design

Bill Genc of TopSolid shares his perspective on the benefits of and barriers to using artificial intelligence in mold design.

.jpg;maxWidth=300;quality=90)