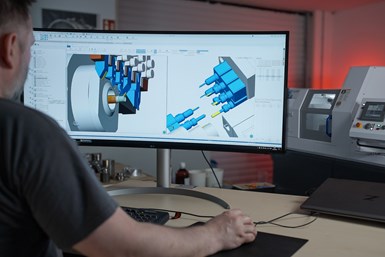

CAM Software Solutions Streamline CNC Machining

SolidCAM’s iMachining provides users with optimal automatic feeds and speeds with the patented Technology Wizard.

SolidCAM highlights CAM solutions for faster, more efficient machining — seamlessly integrated and associative in Solidworks, Solid Edge and Autodesk Inventor.

SolidCAM’s iMachining is said to save 70% or more in CNC machining time, increase tool life 5X or more and provide users with optimal automatic feeds and speeds with the patented Technology Wizard.

Additionally, SolidCAM’s Multi-Channel mill-turn and Swiss-type CAM includes post-processors for all complex mill-turn and Swiss-type CNCs. Users can optimize their machining with SolidCAM’s Multi-Channel synchronization and see complete machine simulation for safer machining.

Users can leverage metal 3D printing with SolidCAM Additive, which provides cost-effective, combined 3D metal printing and CNC machining. With hybrid manufacturing, users are also able to 3D print a part in metal, then CNC finish it, saving costs compared to traditional manufacturing. SolidCAM helps guide the entire process from design to 3D printing to CNC machining.

Related Content

-

What Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

-

Tolerancing in Mold Design, Part 2: Using GD&T to Address Conventional Tolerancing Issues

Mold designers can achieve a single interpretation of workpiece functionality when following the American Society of Mechanical Engineers Geometric Dimensioning and Tolerancing standard.

-

OEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

.jpg;maxWidth=300;quality=90)