Robotic Programming Suite Introduces Enhanced Functionalities, Improvements

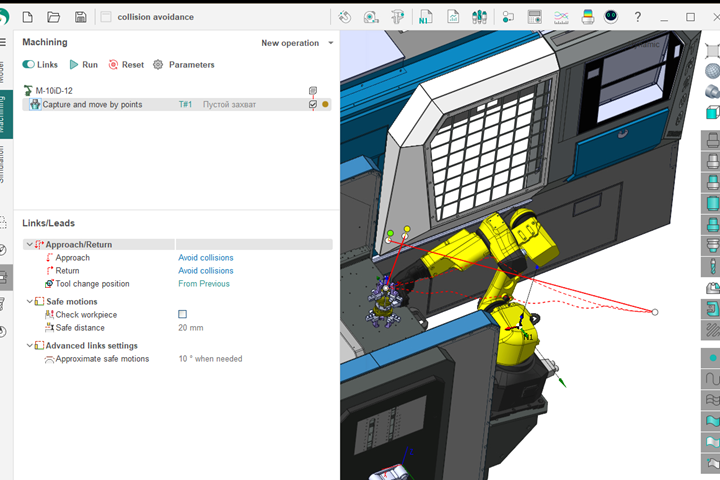

SprutCAM X, an all-in-one CAD/CAM/OLP software suite for complex and creative robot tasks, has updated its Collision Avoidance feature, amongst others for a more streamlined experience.

CAD/CAM/OLP developer SprutCAM Tech is releasing the 17.0.10 update for SprutCAM X, the company’s all-in-one CAD/CAM/OLP software suite for complex and creative robot tasks. This update introduces enhanced functionalities, bug fixes and improvements designed to streamline the user experience.

SprutCAM X is an offline robot programming workflow that demonstrates machine-aware programming, obviating the requirement for repetitive reprogramming and re-verification cycles; SprutCAM cites a 50% reduction in programming time compared to traditional CAM workflows.

A key enhancement in SprutCAM X and SprutCAM X Robot 17.0.10 is the Collision Avoidance option, which now features an updated calculation algorithm. SprutCAM X excels in finding safe tool approach and return paths even in complex machining environments. Additionally, the updated software prioritizes user convenience with several updates:

- Added tool axis orientation along the normal to the base surface in the Pocketing operation.

- Organized list of post-processors in the control program creation window.

- Support for non-milling tools for milling machines in MachineMaker.

- Warning when clicking “clear all” in the Snapshots Manager window.

- Arc interpolation to the Area Cladding operation.

Some notable bug fixes that have been implemented include:

- Resolved errors when adding a new robot and when working with templates in MachineMaker.

- Fixed critical and visualization errors related to drawing modes and 3D models.

- Addressed a bug with the Collision Avoidance option.

- Fixed bugs related to inch and metric measurement systems.

- Resolved issues with importing and viewing 3D models from SolidWorks, IronCAD and Inventor.

In this release, SprutCAM X has incorporated a total of 123 changes. Users with an active maintenance software contract have already received notifications for the new release and can proceed with the upgrade.

Related Content

-

Advancing Moldmaking and Plastics: Trends in 3D Printing, Automation and Sustainability

NPE 2024 showcased the latest trends and technologies in innovation, efficiency and sustainability for moldmakers and molders, featuring advancements in 3D printing, automation, design and virtual reality/augmented reality/artificial intelligence.

-

Five-Axis Graphite Mill With Automation Debottlenecks Electrode Machining

Five-axis electrode cutting enabled Preferred Tool to EDM complex internal screw geometry on an insert that otherwise would have had to be outsourced.

-

Achieving Flexible Capacity with Automation

This high-mix, low-volume manufacturer embarked on a year and a half program to introduce robotics to its manufacturing process.