RP/RT Technologies Offer Speed, Consistency for Consumer Products Molds

The constantly changing world of consumer products warrants molds that can be produced quickly while still maintaining high quality.

The consumer industry encompasses a wide range of products that can range from health/beauty, sports/recreation to appliances/home goods. Such a diverse amount of items can dictate a whole host of different mold build requirements. One thing that these products all have in common is that consumers are always looking for something new and exciting. Thus, producing molds for the consumer products industry in a compressed timeframe is a great opportunity to tap into this market.

The consumer products market has proved lucrative for Clinton Township, MI-based Complete Prototype Services (CPS)—a fast-growing company that produces workable prototype parts and tooling primarily for the consumer products and automotive industries. Incorporated in 1995, the company specializes in prototype and limited production molds—providing complete design, build and evaluation of prototype tooling; rapid tooling; fixtures; models; and mock-ups utilizing wood, spray metal epoxy, aluminum and steel. Today, the company has five facilities and employs approximately 150 people.

According to CPS President Chris Michayluk, the majority of work it completes in the consumer products industry is molds for clear crisper bins in refrigerators, white ice trays, refrigerators, boat seats, duck decoys, water bottle caps and test equipment. Wayne Hertlein, CPS plant manager for the company’s Fraser molding facility, notes that CPS is receiving more orders in this industry because manufacturers don’t want to go overseas when these products have such quick turnaround times. “Some trends we are seeing in the consumer products industry are demands for higher quality and shorter leadtimes,” Hertlein notes. “And—because products in this industry change quite a bit—we are doing limited production runs. We are not tooling up for the high production anymore because it is pretty much two years in, two out. Today’s consumers can get bored easily and want to see something new.”

Consumer Challenges

Not surprisingly, building molds for the consumer products industry poses similar challenges that molds in other markets face. Michayluk notes that the molds are more complex with less money and time to complete the project. “It is because of the cutting-edge technology combined with our experience that we are able to compete,” Michayluk states.

There is no magic formula regarding tolerances, accuracy or finishes. “It really depends on the type of mold we are building and the customer’s requirements,” Hertlein says. “When the part is visible, obviously a better finish is required.”

A Custom Program

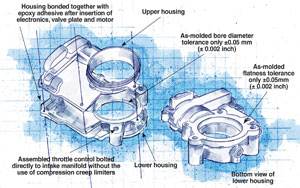

Recently CPS developed a program for SPX Corporation, a large supplier of test equipment and automotive tooling, whose end customer is Snap On. The mold is for a Freon reclamation system used in air conditioning units. “The company was being supplied parts that were structural foam molded (see Molding Terminologies below),” Michayluk notes. “They then decided they wanted take a different direction to go with their next-generation of product.”

CPS worked closely with the supplier to develop a program that was right for them. “At first, we thought a gas assist program would work best for this particular mold,” Hertlein explains. “So we helped develop a tooling program that worked with their requirements. Although they had their heart set on a structural web program, we believed that gas assist would provide a more robust product. After going through the gas-assist process, we re-engineered the parts again to be conventionally injection molded by doing some redesigns of the part and changing some wall thicknesses and rib thicknesses.”

As a result of the new injection molding program, the test equipment supplier was left with an improved process that consistently made better parts, according to Michayluk. This improved the end product’s quality, reduced scrap and minimized surface defects. Additionally, the overall weigh of the part was reduced—providing material cost savings.

CPS was able to develop this program in just six weeks. “We would have liked six months to develop this program, but we needed to meet our customer’s needs,” Hertlein comments. “There was a lot of collaboration, communication and cooperation between us.”

Michayluk adds that it is just this type of thinking outside of the traditional moldmaking box that has made CPS such a success. “You have to be creative and reinvent your business every day,” he emphasizes. “Don’t be afraid to try and push the limits. Look for ways to cut corners—and costs—while adding value for your customers. This philosophy has proved beneficial for CPS. The consumer products market has a promising future—it is constantly evolving.”

Related Content

3D Printing Technologies for Moldmaking Applications

3D printing technologies, from conformal cooling to complex mold building, are making an impact on the moldmaking industry, one innovation at a time.

Read MoreThe Benefits of Vertically Integrating Metal 3D Printing and Machining

Having 3D printing and machining within one organization enables Addman’s engineers to collaborate and consolidate so it can quickly make successful metal 3D-printed parts.

Read MorePrecision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

Read MoreMMT Chats: The Connection Between Additive Manufacturing Education and ROI

This MMT Chat continues the conversation with Action Mold and Machining, as two members of the Additive Manufacturing team dig a little deeper into AM education, AM’s return on investment and the facility and equipment requirements to implement AM properly.

Read MoreRead Next

Canon Virginia, Inc.: From Captivity to the Open Market

This world-renown imaging company proves its worth in the moldmaking market by adding value to the process with turnkey operations.

Read MoreNew PET Bottle Standard May Boost Business for Moldmakers

A rule to lightweight preform necks and closures could require more than 1,000 new molds.

Read MoreMold Builders Carve Lean Niche

Commodity-oriented consumer manufacturing left North America, but mold industry survivors are finding strong growth in technical market sectors.

Read More