A Copper-Nickel-Silicon-Chromium Alloy for Mold Tooling

A review of the physical and mechanical properties of one copper alloy system will help moldmakers better understand how this alloy will perform thermally and mechanically in applications.

There are many industrial uses for high strength, high conductivity alloys. Copper, in its pure form, provides high conductivity, but has insufficient strength for many industrial applications, such as injection molding cores and cavities. Alloying copper with elements such as aluminum and tin improves the strength, but seriously deteriorates conductivity. One copper alloy system developed in the 20th century that provides good strength and conductivity is the copper nickel silicon system.

In 1928, this copper metal-silicide alloy system was patented by Michael Corson.1 It was subsequently known as Corson bronze. In this alloy, the silicide could be nickel-, chromium- or cobalt-based. In copper, a small addition of silicon and nickel or cobalt in a stoichiometric ratio of 1:2 results in the formation of an X2Si silicide that has a significant strengthening effect on the copper—while keeping thermal and electrical conductivity nearer that of pure copper. Likewise, chromium will form a Cr2Si3 silicide. However, with a Brinell hardness of only 135 (75 HRB), the simple silicide system found limited use.

The alloy system found widespread application in the plastic mold industry with the introduction of a copper alloy2 that contained both nickel and chromium silicides. With a two-stage aging process, this alloy provided hardness in excess of 92 HRB and conductivity in excess of 200 W/m/K. This alloy was given UNS designation C18000, with an approximate composition by weight of 2.5 percent nickel, 0.75 percent silicon, 0.4 percent chromium and the balance copper.

Modifying C18000 by increasing the nickel concentration to about 7 percent and silicon to about 2 percent by weight resulted in a higher strength Corson bronze (denoted in this paper as CNS-V for copper nickel silicide, version 5).3 With a hardness of 29 HRC and a thermal conductivity of about 140 W/m/K in wrought sections larger than 25mm, the alloy found application as a replacement for mold alloys such as P-20 tool steel and C17200 copper beryllium. As this alloy system is fairly young, a review of its physical and mechanical properties will help moldmakers better understand its applications, benefits and limitations. These are compared with that of other common mold materials to aid the designer in using this alloy in mold tooling.

| Table 1 | |

| Property | Test Method |

| Electrical conductivity | ASTM E 1004 |

| Thermal diffusivity | ASTM E 1461 |

| Heat capacity | ASTM E 1269 |

| Hardness | ASTM E 10, E 18, E 384 |

| Tensile properties | ASTM E 8, E 111 |

| Compression strength | ASTM E 9 |

| Impact strength | ASTM E 23 |

| Fatigue strength | rotary fatigue* |

| Measured physical properties and the ASTM test method employed. *No ASTM test method published. Tables courtesy of Brush Wellman. | |

Thermal Conductivity Background

The primary attribute of CNS-V that makes it attractive to the mold industry is its high thermal conductivity (high strength is easily provided by tool steels). With conductivity in excess of five times that of common tool steels, the alloy can be used in injection mold core and cavity applications to remove hot spots, reduce warpage and reduce cycle time.4,5 The overall effect is better productivity.

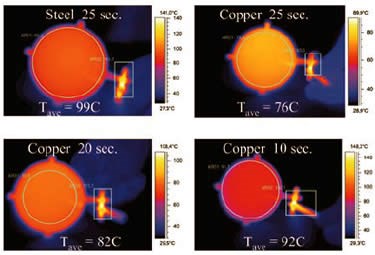

To demonstrate the cooling efficiency of high conductivity mold materials, a case study was conducted in which polycarbonate ophthalmic lenses were molded in 24 W/m/K (14 Btu/hr/ft/°F) 420 stainless steel inserts and also in 130 W/m/K (75 Btu/hr/ft/°F) C17200 copper alloy inserts. The polycarbonate lenses were 2 mm thick and formed from an ophthalmic grade polycarbonate injected at 310°C. Cooling water was circulated at 55°C. Thermographic images of the lenses ejected from the mold are shown in Figure 1. The images show that even with a cooling cycle 60 percent shorter (10 vs. 25 seconds), the high conductivity mold provided more cooling than the stainless steel mold.

Test Procedures for Evaluating Mold Alloys

The properties measured on one or more samples of CNS-V and their respective ASTM test methods are given in Table 1. Only the rotary fatigue testing lacks a recognized test procedure. This testing is performed by rotating a rod with a reduced mid-section while applying a fixed moment on the axis (see Figure 2). This results in a fully reversed load (R= -1) on the center of the test rod. This testing is known as RR Moore testing after the manufacturer of this type of apparatus.

| Table 2 | |||||

| Property | Units | CNS-V | C17200 LH | C96970 CuNiSn |

AISI P-20 |

| Hardness | HRC | 28 | 30 | 29 | 32 |

| Tensile Yield Strength | MPa | 790 | 770 | 720 | 895 |

| Compressive Yield | MPa | 827 | 850 | 790 | 850 |

| Ultimate Tensile Stength | MPa | 880 | 960 | 770 | 1020 |

| Elongation | % in 3D | 7 | 15 | 6 | 20 |

| Elastic Modulus | GPa | 137 | 137 | 125 | 205 |

| 107 Fatigue Strength | MPa | 275 | 345 | 250 | -- |

| Charpy Energy | J | < 7 | 8-20 | 19 | 30 |

| Thermal Conductivity @ 100° C | W/m/K | 160 | 155 | 67 | 29 |

| Heat Capacity | J/kg/K | 410 | 435 | 390 | 460 |

| Electrical Conductivity @ 20° C | MS/m | 18-20 | 16-20 | 8.0 | -- |

| Density @ 20° C | kg/m3 | 8690 | 8320 | 8940 | 7800 |

| Useful properties of several mold alloys. | |||||

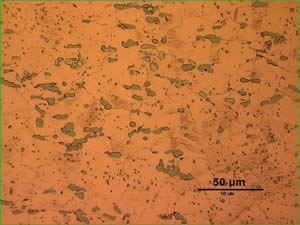

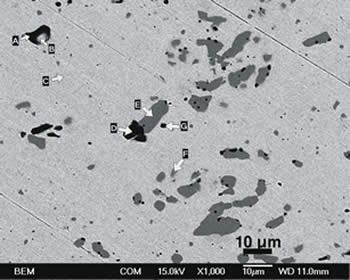

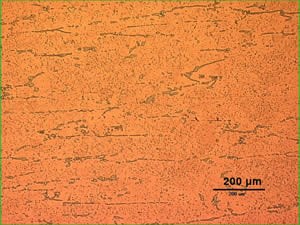

Microstructure

An SEM micrograph (backscattered electron image) of a polished CNS-V sample is shown in Figure 3. The large 10 micron regions are Ni2Si particles, while the smaller dark regions are Cr2Si3 particles. An optical micrograph of that material at 260X is shown in Figure 4. Another optical micrograph at 50X, shown in Figure 5, shows much larger (100 micron) Ni2Si particles that are elongated in the rolling direction of the plate. In large sections, the best microstructural quality that one can expect from this alloy is something consistently like Figure 4. In many cases, the material will contain large precipitates which can adversely affect fatigue strength, toughness and surface finish.

Results of Conductivity Testing

The electrical conductivity is dependent on the heat treatment of the material. The alloy attains its minimum conductivity (and strength) after solution annealing, the initial heat treatment after hotworking. A conductivity near 18.0 MS/m (31% IACS) and maximum strength is achieved after aging at intermediate temperature. Figure 6 shows a relationship between electrical conductivity and tensile strength for a single heat of material that has undergone several different overaging heat treatments beyond the peak strength.

The thermal conductivity of three samples was measured. Two of the samples were from different orientations of the same plate: one normal and one perpendicular to the surface. This plate has a room temperature electrical conductivity of 18.0 MS/m (31% IACS) and a nominal hardness of 28 HRC. The other sample has a room temperature electrical conductivity of 19.7 MS/m (34% IACS) and a hardness of 26 HRC.

The thermal conductivity from the 18.0 MS/m plate differed by about 2 percent between the two directions. At room temperature, the thermal conductivity was calculated to be 140 W/m/K (81 Btu/hr/ft/°F). This yields a Lorenz number6 of 2.65 x 10-8 W-ohm/K2. The 19.7 MS/m sample had a room temperature thermal conductivity of 162 W/m/K (94 Btu/hr/ft/°F). This yields a Lorenz number of 2.78 x 10-8 W-ohm/K2. This Lorenz number is consistent with that of other copper alloys and allows measurement of the electrical conductivity to provide a good approximation of the thermal conductivity.

Like most copper alloys at near room temperature, the thermal conductivity increases with increasing temperature. At 150°C, the 18.0 MS/m sample reached a conductivity of 174 W/m/K (100 Btu/hr/ft/°F). The 19.7 MS/m sample reached 198 W/m/K (114 Btu/hr/ft/°F). A graph of the temperature dependence of the thermal conductivity is given in Figure 7 for the 18.0 MS/m sample.

Results of Mechanical Testing

The highest mechanical properties measured on a commercial sample of CNS-V were 883 MPa (128 ksi) ultimate tensile strength, 800 MPa (116 ksi) yield strength at 0.2% offset and 29.0 HRC. The measured elongation of this sample is 7.5% and its electrical conductivity is 18 MS/m (31% IACS).

Figure 8 shows the correlation between hardness and the ultimate and yield tensile properties derived from various heat treatments of 50 mm plate. These data are consistent with the alloy achieving a hardness of 29 HRC at a tensile strength of 883 MPa and yield strength of 800 MPa.

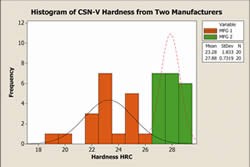

A histogram of Rockwell C hardness from two other suppliers is shown in Figure 9. None of the readings exceeds 29 HRC. The hardest commercially available material that was tested averaged 27.9 HRC. Brinell hardness testing of this plate averaged 281.4 HBW. Conversion to HRC per ASTM E 140, Table 1 is 29.4. Rockwell hardness measurements are generally lower on average and show greater variation. This is probably due to the fact that the larger Brinell indenter contacts more of the harder silicides than the Rockwell C indenter.

Figure 10 shows a “SN” (stress, cycle number) fatigue graph of CNS-V and C17200 copper beryllium. The graph shows CNS-V to have slightly lower fatigue strength than copper beryllium. For CNS-V, two samples per stress level were measured and the highest cycle count is displayed. The data for copper beryllium are typical values derived from a much larger set of values that were averaged.

Comparison with Other Mold Alloys

A comparison of several physical properties of common mold alloys is shown in Table 2. C17200 LH is over-aged C17200 copper beryllium. C969707 is UNS C96970 Cu-Ni-Sn spinodally hardened alloy. AISI P-20 is a Cr-Ni-Mo tool steel. All of these alloys are supplied in the 26-32 HRC hardness range. The hardness and thermal conductivity are summarized in Figure 11.

The data for P-20 were taken from published datasheets. The data for CNS-V were derived from a small number of measurements on some commercially available material (approximately 50mm thick plate) and some developmental material. Except where ranges are used, these data represent the properties of the “best-in-class” sample. The tensile and CVN data for C96970 are mean values for a large number of production samples. The tensile data for copper beryllium are the mean values for a large number of production samples. Compression and thermal conductivity data for all the copper alloys are from a small number of samples (from one to three).

Applications

With its high strength and conductivity, CNS-V has many applications in the mold industry. In blow molding it can be used as pinch-offs, neck rings and handle inserts. In injection molds, common applications include cores, inserts and slides. Other uses include sprue bushings and ejector pins. Because of its high upper working temperature (425° C), it also can be used successfully in hot runner nozzles; although being a high copper alloy, it is susceptible to oxidative corrosion at elevated temperatures.

Conclusion

CNS-V is an alloy system capable of achieving a maximum hardness of about 29 HRC at a thermal conductivity in excess of 138 W/m/K. A comparison with copper beryllium shows it may be a suitable replacement in applications where strength and hardness is not of paramount importance. However, copper beryllium has slightly higher strength at a similar conductivity. Also, unlike copper beryllium which is capable of 40 HRC hardness, CNS-V doesn’t appear to be capable of consistently providing hardness in excess of 28 HRC. CNS-V does have the advantage of having an upper operating temperature of 425°C while C17200 copper beryllium is limited to temperatures below 315°F.

This article has not dealt with the ability of the suppliers to provide the alloy in large sections. Currently no commercial supplier provides sections thicker than 4 inches. Experience indicates that large sections (greater than 6 inches in minimum cross-section) will not be consistently produced due to difficulties in uniformly heating and cooling such sections during heat treating.

References

- Michael Corson, US Patent 1,658,186, February 7, 1928.

- AMPCOLOY 940® Alloy, presently given UNS designation C18000. Walter Edens and Quentin Ingerson, US Patent 4,260,435, April 7, 1981.

- The versions of copper nickel silicon commercialized other than the original invention (C64700) and C18000 is a cast version containing up to 2% nickel and 1% chromium and a composition with about 10% nickel that proved too brittle for use.

- Paul Englemann, Eric Dawkins, Jay Shoemaker and Michael Monfroe, “Applying Copper Alloys Using New Mold Cooling Software,” SPE ANTEC Proceedings, (1996).

- Paul Englemann, and Eric Dawkins, “Copper vs. Steel Cores: Process Performance, Temperature Profiles and Warpage,” SPE ANTEC Proceedings, (1997).

- The Lorenz number, L, quantifies the proportionality between the electrical conductivity and the thermal conductivity given by κ = LT σ, where κ is the thermal conductivity, T is the absolute temperature and σ is the electrical conductivity.

- Brush Wellman proprietary alloy MoldMAX XL®.

Related Content

How to Fix Predicted Warpage Before It Happens with Windage and CAD Model Morphing

Applying windage and model-morphing techniques saved toolmaker/molder Sturgis Molded Products the time, cost, headaches of multiple part/mold design iteration loops, cumbersome cooling fixtures, and long molding cycles.

Read MoreMold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

Read MoreHow to Select a Mold Temperature Controller

White paper shares how cooling channel analysis, which collects maximum pressure drop, total flow rate and heat dissipation, eases the performance evaluation of mold temperature controllers.

Read MoreWhat is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreRead Next

Choosing the Right Aluminum Alloy for Production Injection Molds

Aluminum may be a better solution than steel after a thorough review of part design, tool design, quantity and type of unfilled, aluminum-friendly resin.

Read MoreIt's a Material World

Strength, hardness and machinability are the common buzzwords that come into play when examining the new materials on the market.

Read MoreMaking the Most of High-Performance Mold Materials

Understanding high conductivity alloys and optimizing their use can help you build better molds.

Read More