An attract, train and retain (ATR) framework offers steps to attract the best talent, enhance their skills through practical training and ensure their long-term commitment to the company. This interconnected approach not only aligns with the evolving dynamics of the workplace, but also fosters a cycle of continuous improvement and excellence within the company.

One step is eLearning and virtual reality training methods that improve a company’s capacity to recruit, educate and maintain a proficient engineering workforce. In today’s rapidly evolving, tech-centric environment, quickly acquiring new skills is essential for maintaining a competitive edge in mold design and moldmaking.

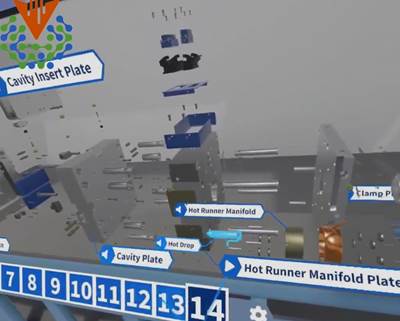

VR-based training plunges learners into a dynamic virtual space where they can engage with 3D models and observe the direct impact of their decisions on mold design.

In an industry where precision, speed and innovation are paramount, virtual reality (VR) offers a powerful tool for attracting and cultivating a highly proficient engineering workforce. Traditional mold design training often involves theoretical knowledge and passive learning. In contrast, VR-based training plunges learners into a dynamic virtual space where they can engage with 3D models and observe the direct impact of their decisions on mold design. This active learning strategy deepens understanding and sharpens problem-solving skills, both essential for the intricate and precise nature of moldmaking.

Here are four benefits of VR in mold design:

Real world simulation. One of the key advantages of VR training is its ability to simulate authentic molding scenarios. Learners can dive hands-on into mold design and production, bypassing the risks and costs associated with physical experimentation. This is particularly beneficial for mastering the precision and quality required in moldmaking.

Scalability and accessibility. VR training is highly scalable and accessible, making it an ideal solution for companies looking to enhance their training initiatives. It offers a cost-effective way to provide premier training resources to teams, leveling the competitive playing field, especially for small- to medium-sized companies.

Technology and practicality. VR training is attractive to young talent, as it merges cutting-edge technology with practical experience. This resonates with the digital-native demographic, helping companies attract and retain skilled engineers. VR is transforming mold design training by offering an immersive, interactive and practical learning experience.

Sustainability. VR is an eLearning technique that contributes to sustainability in the following ways:

- Reduces the carbon footprint due to less travel for training purposes and digital materials reduce the need for paper, contributing to less deforestation and waste.

- Offers savings on physical resources, travel expenses and accommodation for trainers and trainees and enables the efficient use of resources and materials, which can be updated and reused without additional costs.

- Makes education and training more accessible and inclusive. With internet access, people from remote or underserved areas can receive the same quality of training as those in urban centers. This aspect is crucial for global skill development and equitable learning opportunities.

- Enhances employee productivity by offering flexible learning schedules so employees can learn at their own pace, leading to better retention of information, higher job satisfaction and reduced turnover.

- Increases use of analytics to help track progress and tailor learning experiences.

Leveraging eLearning tools and virtual reality, which are accessible universally and round-the-clock, can significantly narrow the skills gap and enhance an organization’s adaptability to emerging technologies.

Related Content

Mold Maintenance Continues to Matter: Enhanced Training Program in a New Facility

I attended a MoldTrax mold maintenance workshop in 2019 and shared my experiences, and despite changes in ownership, the workshop's remarkable value endures, as discussed in a recent Q&A with the current leadership.

Read MoreEden Tool and Eden Manufacturing: A Story of Resilience, Growth and Innovation

This critical parts manufacturer, founded on solid tooling fundamentals, didn’t get derailed with the unexpected passing of the owner because leadership was already building a solid business, not just a good tool shop. Here’s how they managed change incrementally… and they’re not finished yet.

Read MoreMMT Chats: The Science of Moldmaking, Part 2

In Part 2 of this two-part MMT Chat, Christina and Don continue their conversation by exploring lean manufacturing and tips on how to attract, train and retain the future workforce.

Read MoreMaking Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

Read MoreRead Next

How to Learn Mold Design Virtually

Plastics Engineering program instructors share their strategies for successful virtual learning for hands-on injection mold design.

Read MoreAdvancing Mold Design Demo: The Role of VR in Closing the Skills Gap

This Q&A and demo explain how virtual reality training tackles the skills gap by providing immersive, cost-effective learning experiences.

Read MoreVirtual Reality Training for Injection Molding Industry

Kruse Analysis aims to create VR training opportunities for the injection molding industry and to prepare users for work on an actual shop floor.

Read More