Design and Manufacturing Software

Design and engineering is essential to building a better and more cost-effective mold with shorter leadtimes. A variety of software is available to help overcome the daily challenges faced with data, quoting, designing and programming—including computer-aided design (CAD), computer-aided manufacturing (CAM) and data management software. CAM is used to generate machining programs corresponding to part designs; CAD is used for detailed engineering of 3-D models and/or 2-D drawings.

ESSENTIAL READING

VIEW ALLHow to Manage Wall Thickness Changes in Your Mold Design

To ensure even filling and cooling, consider wall section transitions, corners and fillets, ribs and bosses, lip and rim designs and CAE flow simulation software.

Read MoreUnderstanding the Elusive Nature of Mold Ventilation

A personal journey of lessons learned about the challenges of poorly designed, understood and executed mold venting.

Read MoreHow to Fix Predicted Warpage Before It Happens with Windage and CAD Model Morphing

Applying windage and model-morphing techniques saved toolmaker/molder Sturgis Molded Products the time, cost, headaches of multiple part/mold design iteration loops, cumbersome cooling fixtures, and long molding cycles.

Read MoreHow to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

Read MoreHow a Small Programming Change Cuts Cycle Time in Half

Overriding the CAM system when milling a series of lifter pockets helps to improve metal removal rate and increase feed rates.

Read MoreTips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.

Read MoreLatest Design & Mfg. Software News And Updates

AI Increases Efficiency for CAM Programming

Cam-Tool, CAD/CAM software from CGS North America pairs its existing, powerful templates with a new, user-driven AI technology, to increase efficiency and adaptability for CAM programming.

Read More2024 Most-Viewed Products

A comprehensive dive into 2024’s most-viewed products, as revealed through MMT's analytics. This review highlights the most popular products, ranging from technologies, services, softwares and more from this past year.

Read MoreMMT's Most-Viewed Case Studies in 2024

Did you miss any of MoldMaking Technology’s most-viewed case studies from 2024? Now’s your chance to dive into these trending topics.

Read MoreOptimizing Adaptive Sensor Feedback For Low-Pressure Molding

MD&M West 2025: Moldex 3D highlights its adaptive sensor for evaluating and optimizing feedback via innovative processes with simulation.

Read MoreTop 10 Engineering Content From 2024

Peruse the most-viewed engineering content that you may have missed this past year from MoldMaking Technology! Discover the next software to best benefit your moldmaking capabilties – from data management to design and manufacturing software, we have you covered.

Read MoreCNC Control Offers Moldmaking Precision and Process Reliability

MD&M West 2025: Heidenhain Corp. highlights its TNC7 CNC control, engineered to tackle the specific challenges of moldmaking with a focus on precision, efficiency and flexibility.

Read MoreFeatured Posts

2024 Moldmaking Insights: A Year in Review Part 2

A look back at the top moldmaking trends of 2024, as revealed through MMT's analytics. This review highlights the most popular technical articles, case studies, tips and best practices that captured the industry's attention over the past year.

Read More2024 Moldmaking Insights: A Year in Review Part 1

A look back at the top moldmaking trends of 2024, as revealed through MMT's analytics. This review highlights the most popular technical articles, case studies, tips and best practices that captured the industry's attention over the past year.

Read MoreMoldMaking Technology's Most-Viewed Content of 2024

The most popular MoldMaking Technology content according to analytics reports over the past year.

Read MoreHow to Manage Wall Thickness Changes in Your Mold Design

To ensure even filling and cooling, consider wall section transitions, corners and fillets, ribs and bosses, lip and rim designs and CAE flow simulation software.

Read MoreThree Good Reasons to Switch from Three- to Five-Axis Machining in Moldmaking

Five-axis machining technology is a great tool in the moldmaker toolbox.

Read MoreMaximizing Machine Tool Potential With CAM Software

Identifying specific areas where CAM software can utilize machine capabilities to benefit the user and maximize milling machine potential.

Read MoreFAQ: Design & Mfg. Software

What are the benefits of integrated CAD/CAM for moldmakers?

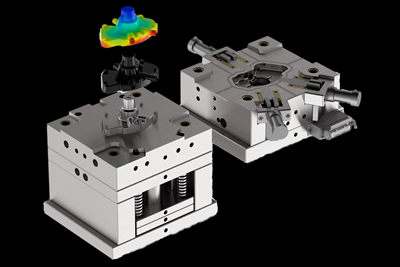

1. Eliminate extra and costly data translation steps between applications that are operating on the same 3-D model. Some systems offer a complete set of fully integrated applications for the complete process from part design through mold design, NC programming, electrode design and CMM inspection programming.

2. Automate more of the manufacturing authoring process: (a) automate NC and CMM programming by using design requirements (GD&T and product manufacturing information (PMI), and color coding) directly on the 3-D model; and, (b) store NC data inside the standard part’s 3-D model file. For example, the NC data inside a standard slide model can be easily updated to its determined design dimensions.

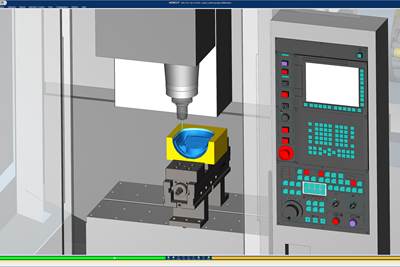

3. Use integrated validation tools throughout the process. Integrated CAD/CAM systems can include tools to validate (and even improve) part and tool designs: molded part manufacturability checks, injection molding simulation and tool motion simulation with collision detection. Before machining, validate NC data with integrated g-code driven machine tool simulation.

4. Keep your data organized so you can work in teams, work in parallel and react faster to design changes. For example, using a master model with associativity allows you to update your mold design, NC programs, electrodes and setup sheets when the CAD model changes. Associativity makes design changes go faster and simple changes can be updated automatically — they don’t require reprogramming because they automatically re-adjust. More than one designer can work on the same tool at the same time; and, you can start NC programming before the tool design is completed.

5. Share knowledge between departments so designs can be done right the first time with manufacturability taken into consideration. When everyone works on the same system, this is much easier to do and the benefits can be substantial. Unfortunately in some cases, designers do not realize the impact of their decisions on the manufacturing process. Design features that are difficult to manufacture can add extra costs to jobs. They can add extra manufacturing steps and extra NC programming time due to feature redesign. When NC programmers and designers work with the same system, it’s much easier for both disciplines to work together. Some CAD/CAM systems have the ability to copy features and store them in a library for later use or can create custom features. When this is the case, NC programmers can work with designers to specify features that include manufacturability considerations. Designers can reuse these features from a library (saves design time) with the confidence that manufacturing knows how to machine them.

When you are able to start with a clean sheet and complete the whole process with the same system, the value of using one integrated CAD/CAM system pays off. Besides the process-based benefits summarized above, additional benefits are to be gained in the forms of reduced training costs due to one easy-to-learn consistent user interface, administration of one system and working with one vendor.

How do you choose a CAD software for 3D mold design?

The main methods for creating designs are solid modeling and surface modeling. Surface modeling was the earliest form of CAD. It is based on shaping surfaces by pulling, bending, twisting and stretching them until the required shape is created. The surfaces can be joined together to enclose a volume and so represent complete objects. Solid modeling is based principally on standard geometric shapes, which can be combined in various ways, mainly developed from the Boolean operations of subtraction, addition and intersection. When they were first introduced almost 30 years ago, solid modelers had the advantage of being much easier to learn and use, but they lacked the flexibility of surface modelers in creating complex shapes. Since then, the developers of surface modelers have made their systems much easier to use, while the suppliers of solid modelers have added more flexible modeling tools. Thus, the distinction between the two types of system is now not so clear-cut.

Core and Cavity Design

Surface modelers still have two general advantages over solid modelers for the first stage of the mold design, the creation of the core and cavity. First, they tend to be more tolerant of poor quality data. Both types of programs offer methods for fixing problems—such as poorly trimmed surfaces or overlapping edges—that might result from inexperienced product designers or inaccurate data translation. However, surface modelers can usually import data that a solid modeler might fail to accept at all.

Many surface and solid modeling programs offer wizards that can automate the creation of the core and cavity design from the part geometry. In both cases, the wizards allow the process to be completed more quickly. However, surface modelers are more flexible when the split surface generated by the automated method needs small adjustments to give the optimal design. In general terms, solid modeling can be better for simpler product designs because it remains easier to use, while the greater flexibility of surface modeling will be better for producing tooling from more complex components.

Mold Assembly

Once the core and cavity have been finalized, work can begin on the remainder of the mold assembly. Since most mold components are made up from fairly simple, prismatic geometry, solid modeling is the most appropriate method for their design and their assembly into the overall mold. Catalogs of standard mold components are required to complete the mold design efficiently as the user does not want to spend time creating these components over and over again. These catalogs are now available in a number of mold design systems, although the range of catalogs varies between the different systems. The software also needs to allow the moldmaker to design—quickly and easily—any non-standard components that might be required since few molds can be completed simply from standard components. Once completed, the designs can be added to the user’s personal catalog for future use.

As well as offering different catalogs, mold design systems differ in the degree of automation they incorporate. Some software includes a special option that allows parametric components to react automatically as they are placed within an assembly, adding all of the necessary fit-features to the connecting components. The software even adds the tolerances needed between the components.

Producing Drawings

Despite the claims made about paperless mold design, all toolmakers still require some drawings for their manufacturing, inspection and assembly departments. However, software suppliers have made considerable steps to automate the process for creating drawings. For example, the new drawing production process within some CAD/CAM software can generate automatically the General Assembly and all of the component drawings required for manufacturing and inspection.

With this high degree of automation, the time needed to produce a complete set of drawings for even a complex mold should be no longer than a day. This compares with the two or three weeks that are typically needed with traditional drawing methods. All dimensions are displayed on the drawings as tables of parameters as well. This makes it much easier and quicker to program 2-D machining operations than the more traditional drawing layout with dimensions displayed all around the drawing.

What are the types of visual search and how can they benefit moldmakers?

There are three types of visual search engines for shapes: Image to Image, 3D to 3D and Cross-Platform. These are designated in shorthand by replacing the word “to” with >, such as Image>Image.

-

Image>Image

This type is used for product visual search, almost always retail. It works by using a photo of the desired product, such as shoes. It then uses this digital photo to find similar digital photos, either on the internet or on an online retailer's website.

For Image>Image web searches, the search engine produces results from its database of images scraped from millions of web pages. This is not proprietary data, but rather visual information readily available on the internet. A reverse version is technology that continually crawls the web, looking for photos that match those in its database. This is typically for finding unauthorized use of proprietary photos, artwork, etc.

For Image>Image searches in a private e-commerce database, consumers are encouraged to use visual search to locate a match, either with a mobile device or a desktop drag-and-drop. This search is limited to those items in that retailer’s e-commerce database.

-

3D>3D

Engineers use 3D>3D searches to find needed models and to avoid duplicated effort. This technology uses a complete or partial 3D rendering to locate existing drawings of a part and may first require text to narrow the category search.

Unlike Image>Image searches, which are useful for both finding and recommending consumer goods, the goal of 3D>3D searches is an exact match. The search returns may be ranked in order of probability of a match, but in an engineering environment, recommendations within a product category serve no purpose.

Using 3D>3D to find 3D models can overcome the following:

-

Language barriers for companies that have engineers and designers creating models in different languages;

-

Terminology barriers, since engineers, may use different nomenclature for the same part; and,

-

Difficulties in naming protocols following a merger or buyout when engineers are accessing an unfamiliar database.

-

Cross-Platform

Cross-platform search technology allows users to perform the Image>Image and 3D>3D searches above, as well as perform searches across file or platform types, such as Image>2D, 2D>2D, PDF>3D, Hand-Sketch>3D, etc.

This is significant for manufacturers. The critical issue for aftermarket sales is that millions of industrial parts are in the field that have never been photographed. With no digital photo in the database, Image>Image search does not work. Cross-platform search solves this aftermarket difficulty by using digital engineering drawings and PDFs as search targets.

Advantages of cross-platform searches include all Image>Image and 3D>3D search capabilities noted above, since this technology encompasses both of these technologies. Plus, it offers the ability to locate one file type using another, such as locating a 3D model with a photo or a 2D drawing with a PDF.

A customer in need of a manufactured component could even draw a hand sketch of the desired part or take a photo of a similar part and send it to the manufacturer. The quoting engineer then uses this as input to instantly pull up existing photos, PDFs, 2D and 3D drawings that match this geometry, dramatically reducing the time needed for quotation.

How can moldmakers choose the right programming software for directed energy deposition when repairing/modifying molds?

It is essential to answer these three questions before selecting programming CAM software for the DED process and to consider the following factors before you make your CAM purchase:

-

Is the software capable of working within a hybrid process?

-

Are you able to create machining and additive operations in the same programming environment?

-

Does the software allow for keeping track of the stock between different types of operations? The ability to generate stock is essential during an additive and subtractive process. It is used to contain the tool path and minimize motion in air, and also is used for collision check with the tool assembly. The stock condition is changing throughout the additive and subtractive processes of a hybrid operation.

Simulation: While it’s true that there is software specialized in simulation, it’s always better to have the part correct the first time as a result of working directly from CAM software, instead of going back and forth between CAM and simulation software. For example, when using additive manufacturing, the software should be able to display the build during the simulation to ensure that the process is building the workpiece correctly.

Some CAM software offering DED options are not offering this capability. This information should also be used by the CAM software to check possible collision with the additive device itself as well as with the machine component. This is especially important when performing five-axis motions during the build process.

Five-axis machining: Five-axis machining capability is essential for the DED process because the deposition process must occur normal to the area on which the machine deposits the material. As previously mentioned, the DED process will most likely not happen on flat surfaces, so five-axis capability is vital. Another reason why five-axis is critical is that the additive device might need to be tilted to avoid existing features or to reach some areas.

The role CAM software has in the five-axis process is also very significant. While smoothness of the five-axis motions is a big factor in machining performance and part surface quality, it is also critical for DED because if the motions are not smooth, the machine will not be able to maintain its speed, causing the additive process to over-build or over-heat.

Post processors: All post-processor technologies are not the same. If you intend to perform complex five-axis motions with an expensive machine tool, you should work with a trusted solution that is proven to be safe, as there are enough variables associated with every new process. Also, ensure the post-processor is prepared to transport the DED technology information to the machine.

Lastly, carefully consider your software source. Since computer-aided DED is new, users might encounter unexpected issues, so it is essential to consult with a knowledgeable software supplier. Before choosing that supplier, ask about the team’s experience with additive manufacturing, assess their willingness to find solutions and inquire about existing partnerships they have with machine tool manufacturers who are involved in the research and development of additive technology.

What are three CAD/CAM automation styles?

- Feature-based automation is programming individual features of a model. Traditionally, these features consisted of various hole and pocket styles. Once you manually defined those features (or as is the case with more advanced CAD/CAM systems, automatically recognize those features), you can apply user-defined macros or sequences of programming cycles to the features. The toolpath cycles should be intelligent enough to adjust parameters for the features automatically, for example, counterbore depth, depth of holes and whether a pocket is closed (requiring ramping stepdown of tools) or open (allowing tools to plunge outside of pocket).

-

Attribute-based automation allows the selection and programming of geometry based on specific attributes applied to said geometry. For example, make the male fillets on a model a particular color of blue (or any pre-determined color) and they are automatically machined; put a closed contour on a level named “Boundary” and it is automatically selected in a semi-finishing 3D Profile toolpath, or select the surfaces that comprise the jaws of your vise and tag them with a user-definable name. Toolpaths will automatically avoid those vise surfaces, ensuring safe, collision-free machining. Adding or changing geometric attributes allows the sorting and selection of geometry and the population of toolpath cycles.

-

Script-based automation is the best of feature- and attribute-based automation but on steroids. Using the full capabilities of a high-end, dedicated CAD system, script-based automation recognizes features, changes the attributes of surfaces, preps the model for manufacturing and so much more. A good script-based automation system uses a CAD/CAM system’s CAD capability much more than feature- or attribute-based automation. It should be capable of patching over holes, coloring planes and radii, creating curves and boundaries and creating layers to populate the created geometry.

Script-based automation can import vises and fixtures, find best-fit coordinate systems and create multi-axis machining vectors. Programmers can apply macros consisting of the full manufacturing process and populate all toolpaths by the geometry the script-based automation generated or manipulated.

How can your CAM software cut cycle time?

Moldmakers often enjoy significant productivity and tool life improvements after adopting high-efficiency and trochoidal toolpaths in metal removal strategies.

Similar productivity success stories in moldmaking are happening by applying new technology through the use of circle segment tools (conical barrel cutters). For shops with five-axis machining centers, this milling approach can yield time reductions of 90% or more and result in better surface finishes.

Source: How a Small Programming Change Cuts Cycle Time in Half

What is the role of model-based definition in mold design?

A primary benefit of model-based definition (MBD) is faster turnaround time. This is important, as a project begins with the customer submitting their part design to the molder as a 3D CAD model—including nominal sizes and locations of the geometry—that are accurate to five or six decimal places. This model serves as the basic, unambiguous definition of size and form with no required dimensions.

Using MBD, the customer can code tolerances, surface finishes and special features onto the faces of the model using color attributes. The model file can also include a table defining each color, as this often varies from shop to shop. These face colors on the product model are then carried directly into the mold design and CAM software to automate cycle parameters, eliminating the need for workers to re-enter critical information from the drawing manually.

Turnaround speed can be increased further by limiting this MBD strategy to classes of parts that support the fastest NC machining and process capabilities. For example, smaller parts without any extra-tight design tolerances and moldable in standard aluminum mold bases.

Source: The Role of Model-Based Definition in Precise Mold Design