Mold Cutting Tools

Cutting tools are used on machine tools to cut metal, and are one component of the overall mold machining process to consider when looking to improve speeds, feeds, wear and surface finish. The broad category of “cutting tools” includes all of the consumable tooling involved in milling, drilling, turning and other lathe and machining center operations. Drills, end mills, taps, reamers and inserts are all included here. Consumable tooling used on certain other types of machine tools is included here as well. Also found here are toolholders and closely related accessories such as angle heads.

ESSENTIAL READING

VIEW ALLHow to Optimize Mold Finishing

Circle segment technology requires fewer tool paths, improving surface quality and increasing cutting tool life.

Read MoreHow to Overcome Deep-Hole Drilling Obstacles in Mold Machining

Keep up with the newest tooling innovations to overcome holemaking and finishing challenges.

Read MoreTen Things You Need to Know about Circle Segment Milling

Considerations for evaluating if circle segment end mills or conical barrel cutters are right for your mold machining applications.

Read MoreHow a Small Programming Change Cuts Cycle Time in Half

Overriding the CAM system when milling a series of lifter pockets helps to improve metal removal rate and increase feed rates.

Read MoreHow to Overcome Cutting Tool Vibration

Advanced indexable milling cutting tool design provides secure, predictable machining, increased metal removal rates, reduced cycle times and fast changeovers.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreLatest Cutting Tools News And Updates

High-feed End Mill Enables Roughing Out Die and Molds

M.A. Ford’s HF high-feed end mill is a tool intended for roughing out die and molds when the material is less than or equal to 52 HRC.

Read MoreDrill Tailored to Challenging Materials Like Stainless Steel and Titanium Drilling

Guhring Inc. highlights the RT 100 InoxPro, a cutting-edge solid carbide drill tailored specifically for challenging materials like stainless steel and titanium alloys.

Read MoreDrilling and Turning Tool Expands Small-Diameter Tool Options

Tungaloy-NTK Inc. announces the expansion of its TungBoreMini series, introducing a new holder for a minimum machining diameter of ø8 mm (.315″).

Read MoreExpanded End Mill Line Offers Multi-Purpose Benefits to Moldmakers

Emuge-Franken USA announces it has expanded three-fold the range of TOP-Cut VAR, the company’s most popular multi-purpose high performance end mills.

Read MoreModular Quick-Change Head System Benefits Various Applications

Iscar USA highlights its new modular quick-change head system for Swiss-type machines intended for turning, grooving, parting and threading applications.

Read MorePCD Milling Cutters Reduce Cutting Forces and Vibration

Walter USA LLC offers the MP060, MP160 and MP260 milling cutters with brazed PCD cutting edges for machining aluminum, aluminum-silicon alloys, magnesium alloys, plastics and fiber composite materials.

Read MoreFeatured Posts

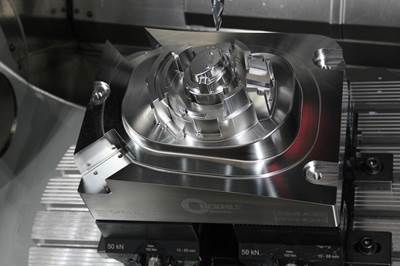

Precision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

WatchHow to Optimize Mold Finishing

Circle segment technology requires fewer tool paths, improving surface quality and increasing cutting tool life.

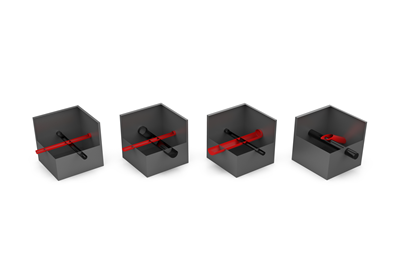

Read More4 Cutting Tool Challenges and Solutions

A combination of cutting tool carbide, coating and geometry helps tackle four mold machining challenges and improve cutting performance.

Read MoreTechnology Review and Sourcing Guide 2024: Cutting Tools

Mold cutting tools are used on machine tools to cut metal and are one component of the overall mold machining process to consider when looking to improve speeds, feeds, wear and surface finish. Access this exclusive, online-only content, including a suppliers list, cutting tool products and more.

Read MoreHow to Overcome Deep-Hole Drilling Obstacles in Mold Machining

Keep up with the newest tooling innovations to overcome holemaking and finishing challenges.

Read MoreTen Things You Need to Know about Circle Segment Milling

Considerations for evaluating if circle segment end mills or conical barrel cutters are right for your mold machining applications.

Read MoreFAQ: Cutting Tools

Why is through-tool coolant valuable, and why are shops are seeing greater need for it?

Getting coolant to the cutting edge is critical for any manufacturing application. It helps in cooling the cutting zone, provides very needed lubrication, and can assist in breaking a chip. Many times, external lines are used to splash coolant near the work zone. Long Chips can easily interfere with this delivery method, possibly knocking the lines out of the way. Additionally, when tools need to be changed or indexed coolant lines might be moved for better access to the tool. Then when the line is put back it is never the same as it previously was. Often times there is a give-and-take methodology used to cover areas being machined with this coolant, so all tools get some cooling, but none of them get ideal cooling. A coolant-through tool allows pinpoint accuracy with a specific direction of coolant pointed exactly at the cutting zone.

Through-tool coolant is available on cutters that couldn't offer it before. What has changed in the technology of tool manufacturing to make this possible?

There’s been a big change is the ability to drill small-diameter holes very deep and do this in a production atmosphere. Part of this comes from the drilling machines being able to reach the necessary speeds and holders that provide superior clamping and runout. The other part comes from tools designed specifically for this drilling application.

On a coolant-through tool, material could be added in areas that may need additional strength, allowing for the intersecting coolant ports to be drilled accordingly.

What aspect of tool engineering is responding to greater cutting speed?

Machines and tools seem to have a back-and-forth dance in terms of which is leading. Coatings continue to evolve, with more layers, and different material being used. This is something all tool manufactures are playing with on some level. The changes in coating technology is somewhat more limited, and not as many are playing in this arena. One process that comes to mind is “HiPIMS,” or high-power impulse magnetron sputtering. This process uses microsecond timing of extreme-power pulses. This allows the metal to ionize to nano size particles to be deposited on the tools. This process allows for greater adhesion and coating hardness, while maintaining great lubricity. Additionally, this process has greatly reduced compressive stresses. This reduction allows for smaller edge preps to be used, thus resulting in sharper tools.

Why is diamond used as an industrial cutting tool?

Developments in polycrystalline diamond (PCD) and cubic boron nitride (CBN) have allowed these materials to improve in ways that make them more versatile and cost-effective. Meanwhile, the machining speed and tool life of these tools continue to take machining processes to levels of performance where carbide cannot go.

Through long tool life and fast cutting parameters, the tools increase machine capacity by reducing the frequency of tool replacements and allowing machines to make parts at a greater rate. Meanwhile, the tooling increasingly figures into expert solutions tailored to more demanding applications in various industries.

Source: The New Rules of Cutting Tools - Rule #3: Diamond Shouldn't Be Rare

What are cutting tools made of?

Polycrystalline diamond (PCD), cubic boron nitride (CBN), ceramic, high-speed steel (HHS), cemented carbide or cermet.

Sources: What's Happening With Cutting Tools

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)