Mold Components

Stainless Steel Sealing Plugs Feature High Corrosion Resistance

Reliable injection mold cooling is achieved by Hasco Z9425/.../VA seal plugs, with temperature resistance up to 180°C and up to 10-bar internal pressure.

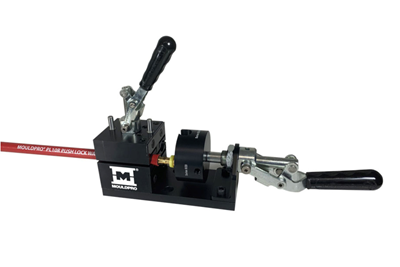

Read MoreHose Assembly Tool Makes Easy Work of Coupler Assembly

From the Mouldpro line, Globeius introduces a hose assembly tool solution for getting the right couplers for mold cooling line needs.

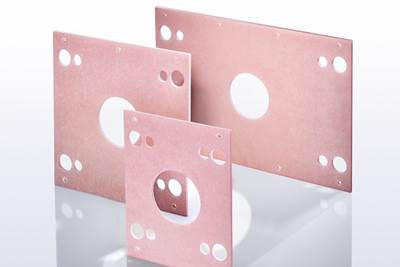

Read MoreDrilled Thermal Insulating Sheets Well Suited to Prevent Uncontrolled Heat Dissipation

Particularly suited for use in highly stressed molding tools, Hasco’s pre-drilled thermal insulating sheets feature high dimensional stability, heat resistance.

Read MoreProduct Innovations Pushing the Mold

Another tech roundup is here to provide an overview of technologies and services on the market for moldmakers. Featured in this roundup are cutting tools, mold components and more.

Read MoreScrew Plugs Advance Reliable Thread Sealing

New brass and stainless steel screw plugs from Hasco secure temperature control bore sealing in injection molds.

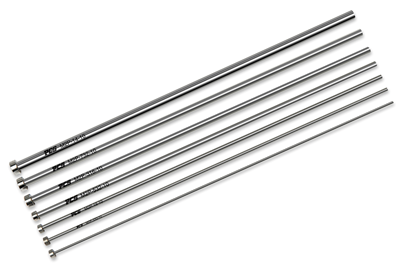

Read MoreHigh-Speed Steel Ejector Pins for Plastic Injection Molds

Latest addition to PCS’ line of ejector pins features high carbon content for higher wear resistance in high-speed steel pins.

Read MoreTechnology and Sourcing Guide 2023: Mold Components

Mold components make the mold work and the mechanisms used to deliver a quality end product. Key components include mold bases, pins, ejectors, lifters, bushings, guides and alignment devices.

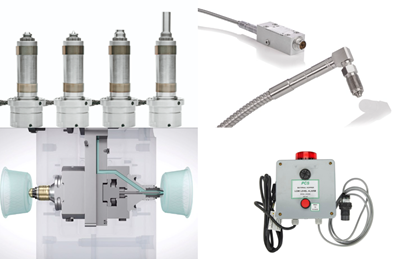

Read MoreSingle-Shot Nozzle Guarantees Efficient Injection Temperature Control

The Single Shot H6300 from Hasco offers an optimal price-to-performance ratio for small- and medium-sized injection molding applications.

Read MoreStreamlined, Customer-Friendly Website Design Helps Modern Moldmakers

Hasco’s newly redesigned website enables users to navigate more than 100,000 products, as well as other innovations and services, easier, faster and 24/7.

Read MoreAn "Impossible" Automation Project Still Proves Invaluable

Two years later and a once-thought-impossible automation solution is still proving its worth to this high-mix, low-volume manufacturer via variable capacity.

Watch