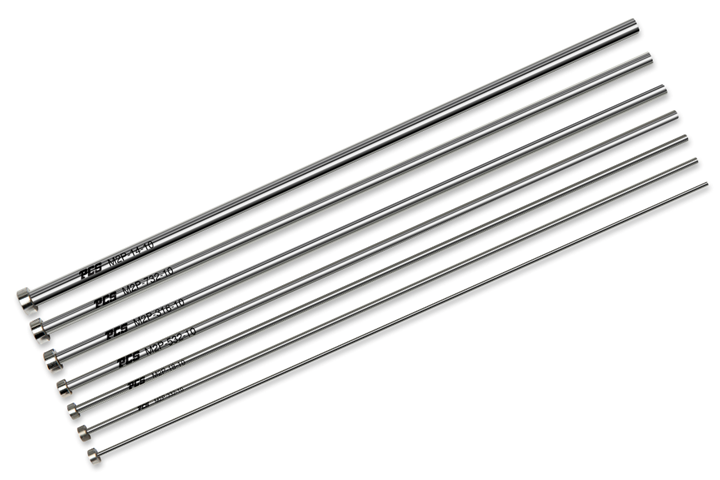

High-Speed Steel Ejector Pins for Plastic Injection Molds

Latest addition to PCS’ line of ejector pins features high carbon content for higher wear resistance in high-speed steel pins.

PCS Company introduces M-2 ejector pins, an enhancement to its already extensive line of high-quality, precision ejector pin products for plastic injection molds.

M-2 ejector pins are made of high-speed steel, which gives them higher wear resistance and better machineability than other currently available pins, according to PCS. Pin diameters range from 1/32" through 1/4" with lengths of 6" and 10". The diameters are precisely ground to provide dimensional stability and high surface finish quality .

“The M-2 ejector pins were added for customers who, increasingly, are requiring the specification of M-2 high-speed steel for their particular molding applications and tool designs,” Paul Hauser, product manager, says.

M-2 ejector pins are through hardened to 60-63 RC, with a diameter tolerance of 0.0003". Additional features include eliminating chipping from form work and their ability to be used either as an ejector pin or core pin

Related Content

-

Revisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

-

Treatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.