Get the Wear Out

An effective way to extend mold life and ease mold warranties is to better manage mold cleaning techniques.

Most would agree that the mold is the heart of the molding process. From those who make molds to those who use them, we all want them to last for as long as they were designed. A lot of work goes into striving toward that goal: good design, proper metallurgy selection, configuration, coatings and much more. Taking all that into account, it’s not surprising molders often want a warranty that ensures the mold will last as long as the desired, if not the quoted, asset life.

So what’s the problem with offering a mold warranty? The reality is that molds don’t always

last as long as they are supposed to, because each facet of a mold’s life can affect its longevity—everything from its design to its maintenance plan. And the proper care of each mold falls to the molder, creating quite the dilemma for a mold builder who is asked to offer a warranty.

Making the Case

Today, expensive and often complex molds may be run and maintained in molding shops and toolrooms by workers with varying degrees of skill. For some, mold maintenance is an afterthought rather than a priority.

A fairly recent industry poll conducted by the American Mold Builders Association (AMBA) found the No. 2 concern for molders is finding ways to improve their “operational excellence” (lean manufacturing, waste reduction, zero defects, higher throughput, continuous improvement, scrap reduction, efficiency improvement). Mold maintenance

can make a significant contribution towards such operational excellence and the life of

a mold, and one of the keys to mold maintenance is mold cleaning. The most commonly used methods for cleaning plastic injection molds have been around for years and involve manual cleaning, however, they can be abrasive and contribute to mold wear.

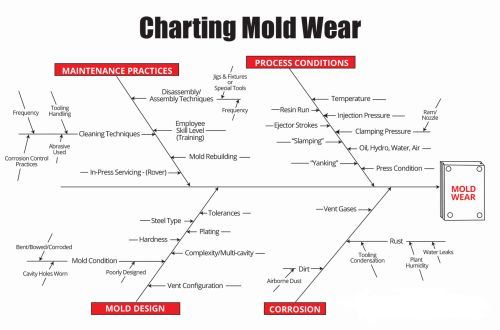

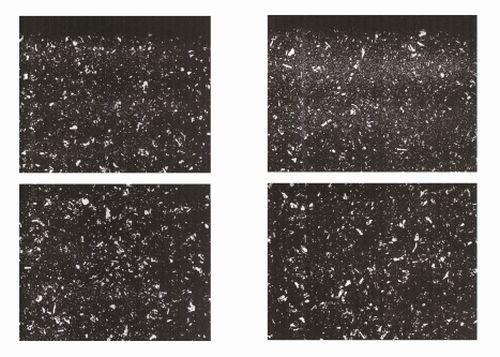

The four common contributors to mold wear are maintenance practices, process conditions, mold design and corrosion (see Figure 1). Within maintenance practices, cleaning techniques, or the method a molder chooses to clean a mold, can particularly contribute to mold wear. As shown in Figure 2, actual mold damage can occur when vents are not properly and routinely cleaned. Here, air trapped inside the mold cavity began to jet or diesel, resulting in damage to the mold.

Reasons a molder may not clean molds more frequently include the fact that traditional manual cleaning methods can cause extended downtime; molds can be too hot from use in molding to handle; cleaning often involves the use of chemicals containing VOCs that employees don’t like to handle and that can leave a residue on the mold that requires further cleaning; and wipes, brushes and other media can be abrasive and contribute to mold wear. Often, traditional manual methods wear away critical mold tolerances of parting lines, rolling over edges, shutoffs and vents. Over time, these cleaning methods reduce the asset life of the mold.

The fact is, molds have to be cleaned, but why does it have to be done in a way that prematurely wears out the mold? What if you could clean your molds not only more often, faster and cheaper, but in a non-abrasive, sustainable, environmentally responsible manner? What if mold cleaning could be better managed, facilitating a platform for mold warranty programs and therefore providing a win-win situation for both the mold builder and molder. One modern method offers these benefits and makes offering mold warranties more attractive to mold builders: dry ice cleaning.

Showing the Data

A study conducted by Kettering University (formerly GMI) in Flint, Michigan, evaluated the effectiveness of non-abrasive mold cleaning with dry ice on various metal substrates. These substrates were subjected to cleaning by full-size dry ice pellets, shaved pellets and shaved block. In Figure 3, the die steel on right side of the green line was blasted with shape block dry ice for 60 seconds at a distance of 1 inch and was found to show “no noticeable damage.” The die steel on the left side of the green line was not blasted.

Another independent study drew a similar conclusion. Figure 4 shows a micrographic examination of the metallurgical structure of martensitic stainless steel (440C) after dry ice cleaning. Noted was the unaltered carbon particles at the core and at the surface, before and after dry ice cleaning.

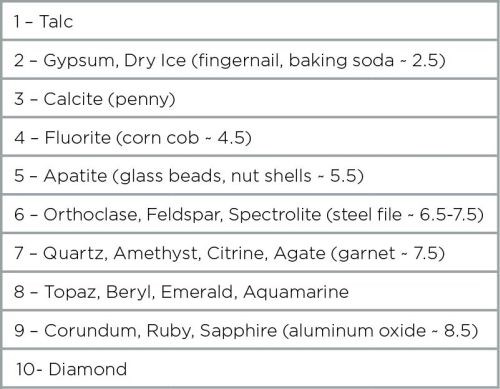

A third study, “Dry Ice Blasting for the Conservation Cleaning of Metals” by Rozemarijn van der Molen, Ineke Joosten, Tonny Beentjes and Luc Megens, revealed that cleaning with dry ice does not damage most industrial substrates because the particles are relatively soft. The hardness of dry ice pellets was found to be 1.5-2.0 Mohs, which is softer than other forms of blast media (see Figure 5), therefore dry ice particles are non-abrasive to any substrate harder than dry ice.

One of the reasons dry ice cleaning is so successful on more delicate mold substrates and complex geometries is its process flexibility. The kinetic energy can be controlled by changing the size of the dry ice particles and the pressure/velocity settings on the machine. For example, gentler cleaning can be achieved by using 0.3-mm dry ice microparticles in lieu of the traditional 3.0-mm pellets (see Figure 6). The smaller-sized microparticles of dry ice require less air to attain full acceleration, bringing gentle but effective cleaning to delicate substrate metallurgies or mold features. The decreased air movement also results in much quieter cleaning operation.

The thermal effect of dry ice cleaning also improves its effectiveness. The dry ice’s inherently low temperature of -109°F (-79.5°C) creates a unique, thermodynamically induced surface mechanism that affects the adhesion of contaminants to the substrate. The process shrinks the contaminant, creating rapid micro-cracking and causing the bond between the contaminant and the mold to fail, enabling the contaminant to be easily removed from the mold. This thermal effect rapidly disappears once the dry ice strikes the contaminant, so the mold itself is not damaged.

Another aspect of dry ice cleaning is the sublimation that occurs when the dry ice makes contact with the contaminants on the mold. Volumetrically, the dry ice will expand around 800 times its size during sublimation, which

essentially enables the contaminant to be blown off the mold from the inside out.

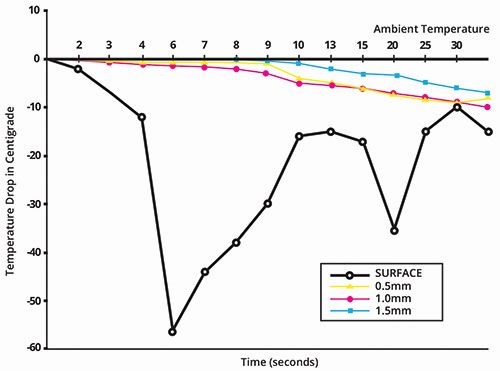

“C02 Pellet Cleaning–A Preliminary Evaluation,” a study conducted by James Snide and published by Materials & Process Associates Inc. in October 1992, measured the thermal stress that occurs during dry ice cleaning. This study showed that the temperature decrease occurs on the surface of the mold only, so there is no thermal stress to the substrate metal. To illustrate this principle, thermocouples were imbedded into a steel substrate at varying depths (from flush with the surface to 2-mm deep). A dry ice particle stream was swept across the test specimen for 30 seconds (a relatively long time for this process), and the thermocouples recorded the changing temperatures at the various depths. As shown in Figure 7, the surface-mounted thermocouple recorded a temperature drop of 50°C in about 5 seconds. In contrast, the other thermocouples imbedded deeper in the substrate recorded slower, gradual

drops in temperature corresponding to the overall test plate temperature drop. The thermo-

couple embedded 2-mm deep only dropped 10°C after 30 seconds. This curve in Figure 7 illustrates that the thermal effect essentially occurs only at the surface where the contaminant is bonded to the mold substrate and has no detrimental effect on the overall mold.

Because dry ice blasting is considered non-abrasive and relies on this thermal effect, the process may be applied to a wide range of materials without damage to those substrates. Soft metals such as brass, beryllium and aluminum cladding can be dry-ice cleaned to remove coatings or contaminants without creating surface stresses (pinging, pitting or roughness).

The bottom line is that an effective way to extend the asset life of a tool and to facilitate mold warranties is to better manage mold cleaning techniques, and dry ice cleaning is a vehicle for doing just that. Molders should be as intentional with their mold maintenance practices as they have been with their scientific molding practices.

Related Content

What is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreThe Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

Read MoreMMT Chats: Eliminating the Noise to Stay Focused on the Customer

Metro Mold & Design joins me to discuss the value of the 80/20 rule as a business strategy, its talented cross-functional team, the role of automation in mold building and molding, and the continuing impact of COVID-19.

Read MoreMaking Mentoring Work | MMT Chat Part 2

Three of the TK Mold and Engineering team in Romeo, Michigan join me for Part 2 of this MMT Chat on mentorship by sharing how the AMBA’s Meet a Mentor Program works, lessons learned (and applied) and the way your shop can join this effort.

Read MoreRead Next

In-Machine Mold Cleaning

Cleaning mold cavities and vents, including those with complex, tight geometries, is critical to producing quality products.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More