Molds and inserts made of a remelted special steel grade can dissipate the process heat from the mold surface within a shorter time. Photo Credit, all images: Swiss Steel USA

A tool steel quenched and tempered to 45 HRC offers a combination of high thermal conductivity, thermal fatigue resistance and good wear resistance, making this specialty steel particularly suitable for applications such as low-pressure die casting, high-pressure die casting (for the gate runner and biscuit area) and plastic injection molding.

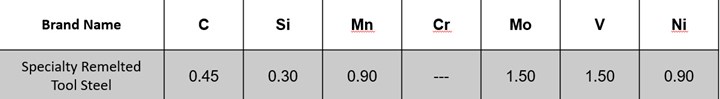

Here are three steel properties to consider when selecting your next mold material to lower cycle times, and a review of how a new specialty remelted tool steel holds up:

-

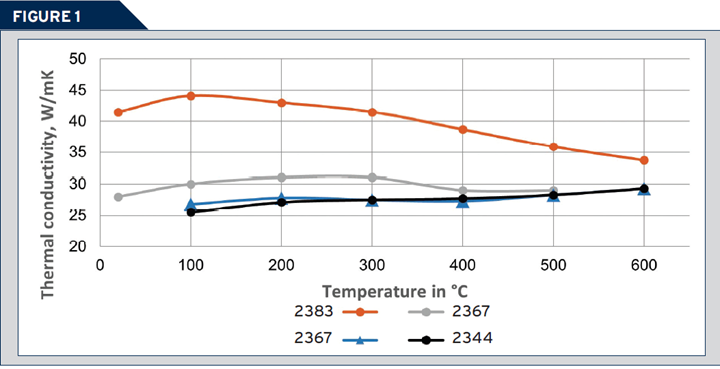

Thermal Conductivity

This specialty remelted tool steel achieves a significantly higher thermal conductivity in the hardened and tempered condition of 45 HRC to 50 HRC than conventional hot work tool steels such as 1.2343 (AISI H11) or 1.2344 (AISI H13) (see Figure 1).

Figure 1. Thermal conductivity of a new specialty remelted tool steel compared to other hot work tool steels in a quenched and tempered condition with a hardness of 45 HRC.

At room temperature, the thermal conductivity is 41.5 W/mK and reaches its highest value of 44.0 W/mK at 100°C. This is about 70% higher compared to 1.2343 and 1.2344, which show thermal conductivities of 25.5 W/mK and 26.8 W/mK at room temperature. The thermal conductivity of this specialty remelted tool steel exceeds conventional hot work tool steels, especially in the range of 100-200°C, which is equivalent to the working temperature in injection molding applications.

Molds and inserts made of this specialty grade can dissipate the process heat from the mold surface within a shorter time, resulting in shorter cycle times and higher process efficiency. In addition, temperature differences between the surface and the mold core are minimized, lowering the mold’s thermal stresses and reducing cracking (see Figure 2).

-

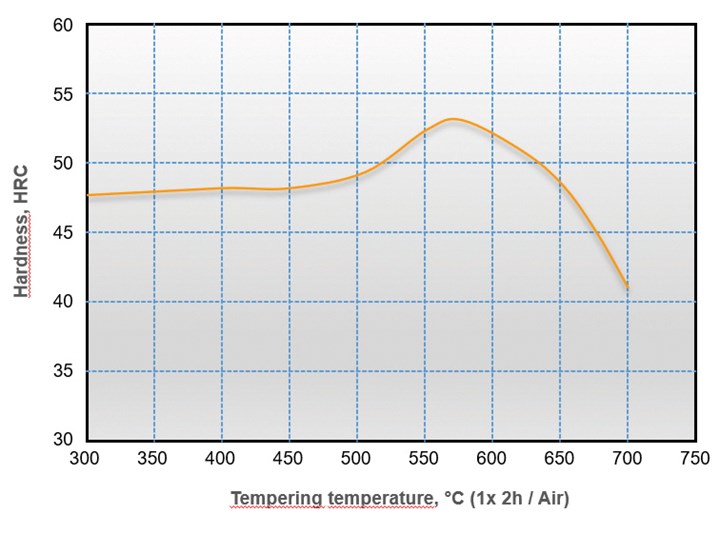

Heat Treatment

The heat treatment (hardening and tempering) differs from conventional hot work tool steels. Molds and inserts should be hardened in the temperature range from 1,050°C to a maximum of 1,090°C, depending on their size. The hardness after quenching is approximately 52 HRC. The secondary hardness maximum of this new specialty remelted tool steel (2383) is around 53 HRC, reaching roughly 570°C (see Figure 3).

Figure 3. Tempering diagram of a new specialty remelted tool steel.

The steel should be tempered twice, similar to other hot work tool steels. Due to its tempering resistance, it is important to temper this steel at higher temperatures to obtain hardness values comparable to those of H11 and H13. Even larger dimensions can easily be quenched and tempered and generate a homogeneous martensitic microstructure.

-

Polishing

Polishability is a critical tool steel property, so polishing trials were conducted to test the performance of this remelted specialty steel (the study used remelted H11 material). The processing time for standard high-gloss polishing is equivalent to H11 ESR.

Related Content

-

Revisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

-

Treatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

-

The Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)