Feature Updates Add to Offline Robotics Programming Software

The SprutCAM X 17.0.11 release includes a comprehensive set of bug fixes and addresses issues concerning software stability, reliability and performance enhancements.

CAD/CAM/OLP software company SprutCAM Tech announces the release of version 17.0.11 for SprutCAM X and SprutCAM X Robot, software that provides offline features for programming various CNC machines used for cutting, wire electrical discharge, as well as two-, three- and and multi-axial machining. Use of industrial robots can enable more efficient production of products and parts with complex surfaces, such as molds. This update introduces a host of enhancements, compatibility with Moka robots and bug fixes.

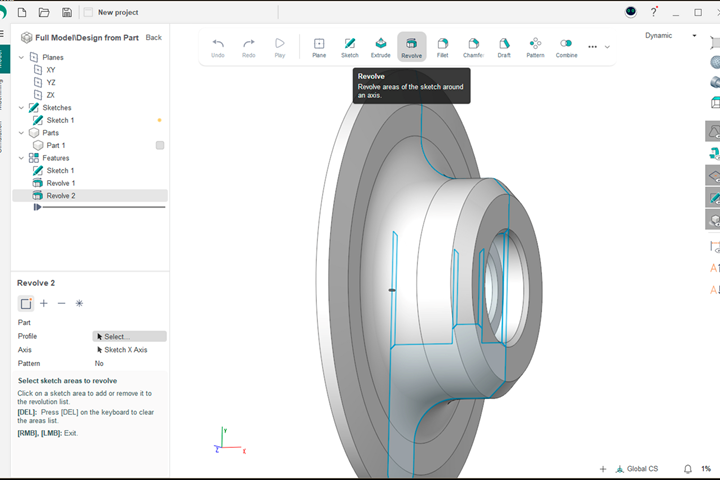

SprutCAM X now enables users to import sketches in .dxf format and seamlessly convert them into sketches within the built-in 3D CAD module. This enhancement facilitates the creation of 3D models of parts for machining projects based on imported sketches.

Moka industrial robots — hollow welding, handling, loading and unloading robots, robots for die-casting and grinding, stamping robots, etc. — have also been added to MachineMaker, the application for creating digital twins of equipment in SprutCAM X Robot. The components library now includes the following Moka robot models: MR07S-930, MR08-1840, MR10L-2050, MR10Z-1440, MR12-2010, MR12Z-1550, MR20-1800, MR20E-1840, MR25ED and MR30-1700.

Updates include improved smart hints for roughing and finishing waterlines, 2D contouring and pocketing operations for a more user-friendly experience. Moreover, the company has updated the list of operations for the 2.5D milling configuration and added chamfering and 2.5D contouring operations to the cutting configuration for robotic machining.

More user interface settings include updates to the font size in the CLData Viewer (postprocessor debugging application) interface, and to the Approach/Return tab in G-code based operations.

Also read, “Robotic Programming Suite Introduces Enhanced Functionalities, Improvements.”

Related Content

-

Tips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.

-

How to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

-

Mold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

.jpg;maxWidth=300;quality=90)