Giving Mold Builders Additive Capabilities, Super Creativity

I saw my first 3D-printed hot runner manifold at K 2019 in Germany, but the system did not have a name yet. Fast forward to 2020 and it not only has a name, but it’s been successfully implemented in a number of applications across Europe. And today, it’s ready for the North American marketplace.

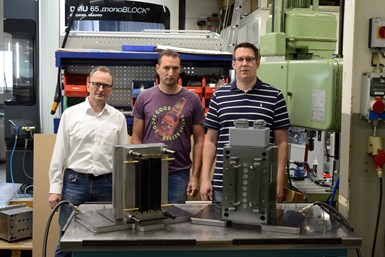

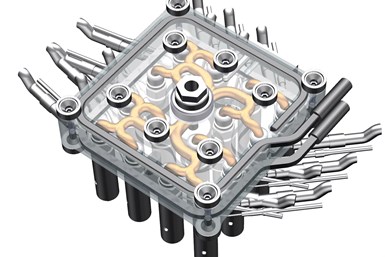

This additively manufactured hot runner manifold offering maximum freedom of design and opening up new options in hot runner technology. Employing simulation-based analyses, specific solutions can be tailored to individual projects. Photo Credit: Hasco

It’s name is Streamrunner®, and it is opening up new options in hot runner technology. “The concept behind the name was to express how material flows from the machine to the cavities—illustrating balance and flow,” says Neville Junkin, a technical engineer for HASCO Hot Runner.

This is a niche product in terms of small pitches and small components, but the applications are many—including medical, and caps & closures. “This is not a silver bullet technology. We still have to look at it from the perspective of running material through the tool and it coming out into the cavities with the required quality for the application at hand,” Junkin says.

The key to this technology is metal 3D printing or additive manufacturing (AM). AM offers flexibility, so designers can arrange nozzles however they’d like.

This system was developed for small pitch applications, so you end up with a very small manifold, reducing print time. If you start getting into larger manifolds, conventional production methods are more appropriate. It is surprising how many applications need this minimal pitch. Junkin notes that customers want to have 18 mm or 20 mm between pitches or between cavities but they can't. Now they can!

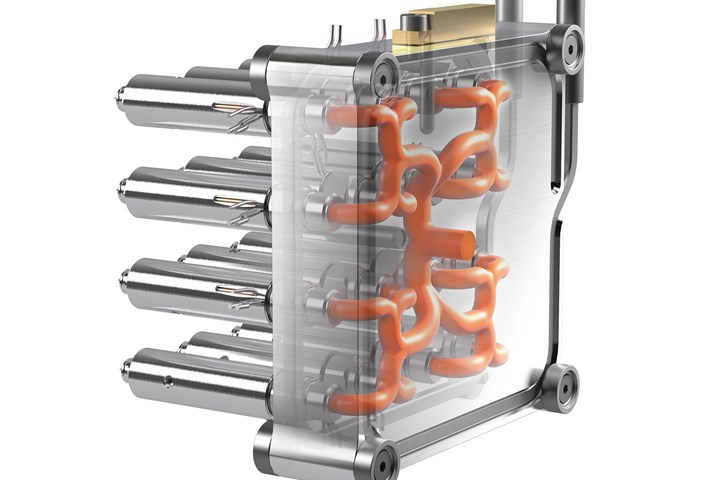

Additive manufacturing technology offers maximum freedom in design and overcomes previous limits on the design of hot runner manifolds—perfect balancing, gentle passage of melt, highly compact design, excellent color change characteristics, suitable for high cavity systems and leak-proof.

The key to this technology is metal 3D printing or additive manufacturing (AM). AM offers flexibility, so designers can arrange nozzles however they’d like.

For example, Junkin explains how they produced a 12-drop system in which they are able to lay out the melt channels any way they want (geometry, length, size, width, etc.) and created a naturally balanced, hot runner system.

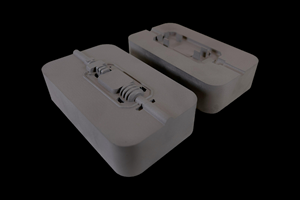

“We have a manifold size of about 6.3 x 6.3 x 2.2 inches using conventional production. So, it's already quite a small manifold. We managed to get a pitch of about 1.2 inches, but it's actually really complicated in terms of tolerance and precision to ensure everything lines up perfectly. We wanted to find a way around using conventional production methods,” Junkin says.

Here, enters AM and the Streamrunner.

“We managed to come up with a manifold solution that is just 4.2 x 4.2 x 1 inch. We're looking at a pitch of 0.7 inch—more than 40% smaller than what we can produce with conventional production methods.”

AM allows Hasco to get super creative with customers when using the this 3D-printed manifold. “We can make systems from four all the way up to 16 nozzles, and then we can put these together with bridging manifolds. For example, a 32-drop system—essentially two 16-drop manifolds with a bridge overtop or four manifolds with a bridge on top, giving us a 64-drop system that is really small—8 x 8 inches,” Junkin says. (The AM manifold I saw on display at the K Show!)

According to Hasco, the benefits include very close to perfectly balanced systems because of the freedom of design that allows them to lay out the melt channels however they want. They also can create long sweeping, curving channels that are really gentle on the material and minimize, or eliminate, dead corners, sharp, edges, and 90-degree angles where material could be damaged and stuck, and, potentially burn. This system also helps with color change.

Using this technology, flow channels can be configured with the optimum rheological layout, avoiding sharp edges and areas with poor flow. The gentle passage of the melt through the manifold makes for considerably lower shear stress in the material, resulting in better quality parts, and the flow-optimized design speeds up color changes too, since the melt can be divided and deflected over generous radii.

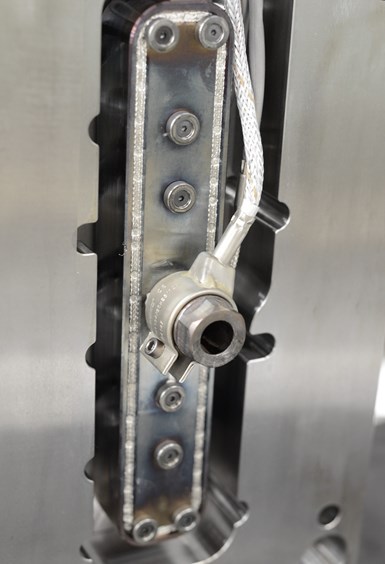

One of the main disadvantages of additive manufacturing is the surface quality afterward, so it's really easy to come back afterward and do some grinding on the outside surface, but when the channels are inside you have to find new methods to ensure that you don‘t end up with burnt material, dead spots, and minimize shearing as much as possible. A unique advantage of this manifold is a proprietary process for smoothening out the channels to remove any dead spots.

And because AM yields one solid chunk of steel in the end with polished channels inside, maintenance is a nonissue. “The first application was 2.5 years ago and the customers still using it with no issues—they haven't needed any spare parts or replacements. No news is good news,“ Junkin says.

These systems also work out to be cost-effective because AM allows Hasco to avoid all of the extra conventional milling and machining that they would generally have to do—especially for high cavity systems with a minimal pitch.

“Our main lesson during all of this development is that we can look at manifold design from a completely different perspective. No more 90 degrees. Now we can be super creative with making balanced systems,” Junkin says.

Best part because of Hasco experience and expert partnerships on this technology even the small mold builder can get involved. They don’t have to say “no” anymore.

“We are essentially giving mold builders the capability to use advanced technology with their customers,” Junkin says. “And, we can adapt our system to their application as opposed to them having to adapt to the more rigid, conventional production methods.”

Related Content

3D Printing Technologies for Moldmaking Applications

3D printing technologies, from conformal cooling to complex mold building, are making an impact on the moldmaking industry, one innovation at a time.

Read MoreMold Builder Uses Metal 3D Printing to Bridge Medical Product Development to Production

Westminster Tool uses metal additive manufacturing for medical device OEM, taking lessons learned from R&D in the prototype mold phase to full-scale production molding in a fraction of the time.

Read MoreMMT Chats: 4 Keys to a Successful Mold-Building Operation: Innovation, Transparency, Accessibility and Relationship

MoldMaking Technology Editorial Director Christina Fuges chats with Steve Michon, co-owner of Zero Tolerance in Clinton Township, Michigan, about the excitement of solving problems, the benefits of showing gratitude, the real struggle with delegation and the importance of staying on top of technology. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreThe Connector Conundrum: 3D Printed Mold Tooling’s Role in Innovation

ReelView Fishing faced an electronics obstacle in the development of its new technology for underwater video. Additive manufacturing for moldmaking enabled the speed necessary to iterate to a solution.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More