Workholding

Selecting the Best Toolholding Solution for Your Shop

A look at ER collet systems and a review of the properties to look for when making your toolholding purchase decision.

Read MoreImproved Profitability through Process Improvement

Hard milling, automation and magnetic workholding are a winning combination.

Read MoreUse Magnetic Chucks to Reduce Your Cost of Operation

By evaluating magnetic devices as a workholding alternative for moldmakers, cost and leadtime can be reduced.

Read MoreSpeed Comes From Your Choice of Machine, But Your Accuracy Comes From Your Choice of Tooling

Innovation in both the design and moldmaking processes has helped one moldmaker stay ahead of the game.

Read MoreIncrease Profitability Through Magnetic Workholding

Milling magnets offer moldmakers the convenience of fully accessible five-axis machining in one setup with the benefits of cost reduction and tolerance improvements.

Read MoreChoosing a High-Speed Spindle for Moldmaking

Many factors - such as mounting style and lubrication choices - need to be considered when choosing a high-speed spindle.

Read MoreStandardized Tooling and Automation Take the Lead Role

A moldmaker and its automation supplier team up to create a global competitor.

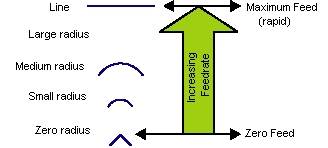

Read MoreBecoming More Accurate With Speed

By adding optimization software to their machining, moldmakers will be able to produce better quality parts with better accuracy.

Read MoreHigh-Performance Machining - Putting It Into Practice

Most companies are looking for three basic things: to make parts faster, better and cheaper. Often, meeting these goals requires a change in process, tooling, the machine tools and/or CAM software.

Read MoreThe Need for Speed

The trend for higher speeds in machining technology has moldmakers scrambling for the cash to purchase this equipment and the subsequent training to bring them "up to speed".

Read More