Workholding

Clamping System Streamlines Palletizing and Clamping to Reduce Setup Time

Röhm Power-Grip Zero Point Clamping System is customizable to the machine, which enables the optimal use of the mahcine’s entire work-envelope space.

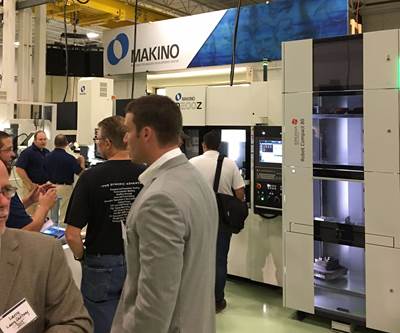

Read MoreThree Takeaways from Die/Mold Expo

What do you gain by attending events like the Makino Die/Mold Expo that was held last week at the company’s Technology Center in Auburn Hills, Michigan? I asked a few of the moldmakers I met there to share their personal takeaways.

Read MoreTechnology Showcase: Case Studies for MoldMaking

It’s time for another foray into past case study features that have been published in MoldMaking Technology Magazine.

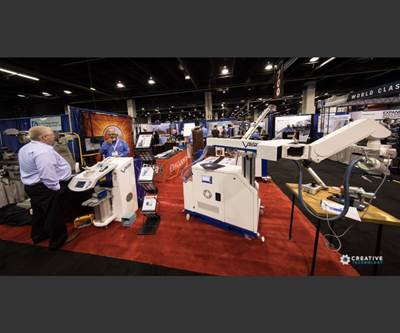

Read MoreAmerimold 2017: Multitudes of Metalworking Materials and Machines

Amerimold proved once again that it is THE event for moldmaking.

Read MoreMagnetic Matters

Understanding the benefits and limitations of different magnetic workholding technologies will help ensure that they are used appropriately and to their full potential.

Read MoreMay the Force Be with You

Unlocking the true potential of magnetic workholding for machining mold bases and inserts lies in understanding clamping and machining forces.

Read MoreBreakthroughs and Possibilities

Okuma’s annual Technology Showcase highlighted the latest innovations in manufacturing technology.

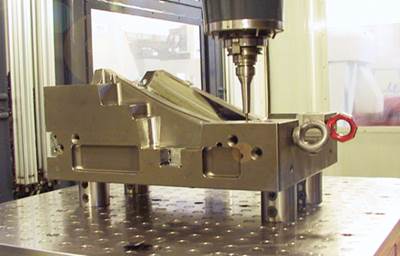

Read MorePlan Your Workholding for Improved Productivity

Choosing and organizing the right workholding can result in significantly improved machine efficiency, and it is essential for reaching any machine’s full potential.

Read MoreMega-Cell: Moldmaking Automation

The Mega-Cell is a production system that ties together all available opportunities to automate and control the process.

WatchPlanned Workholding Increases Mold Shop Productivity

Planned workholding using a modular clamping system is a part of the lean approach to world-class mold manufacturing.

Read More