Workholding

High-Speed Milling Chucks Enable Heavy-Duty Milling

Big Daishowa Mega 12DS power chucks provide users with a highly stable and rigid operation when milling workpieces such as molds.

Read MoreQuick Action Sliding Locks Improve Workholding Setup Time, Reliability

Fixtureworks brings shops a variety of adjustable sliding lock configurations and clamps for those applications where disassembly and changeovers are frequent.

Read MoreLive Tool Expansion for Cutting Tool Tightening Options

North American importer Platinum Tooling offers Heimatec live tools for the Hass BMT turret to ensure more rigid mold machining operations.

Read MoreHydraulic Chucks, Reduction Sleeves Reduce Toolholding Complications

Seco Tools offers a comprehensive range of hydraulic chucks and accompany reduction sleeves, eliminating risk and additional maintenance for mold and die-makers, and less required tooling.

Read MoreManual Machine Vise Handles Prismatic and Round Parts

Roemheld’s PC 80 Clamping System offers fixed jaw and self-centering options and eliminates the need for additional custom workholding solutions.

Read MoreMultifunctional Drilling/Turning Tool Provides Better Chip Evacuation in Small Bore Operations

The TungBore-Mini line has added eight new toolholders that accommodate its XOMU inserts for light cutting, increased security and ample clearance between the tool and the hole surface.

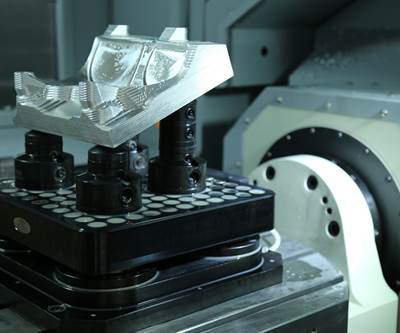

Read MoreRound Pallet Enables Machining with Easier Access Around Workpieces

FCS North America Inc.’s M6 round pallet is designed to address mold and die makers’ need to machine small components.

Read MoreInvestment in Advanced EDM Equipment Sets Shop Apart With Unique Wire EDM Capabilities

Extreme Wire EDM capitalizes on technology investment to carve out competitive advantages serving the moldmaking industry.

Read MoreHow to Design and Analyze the Right Clamping System

The use of innovative clamping systems to optimize the moldmaking production process requires consideration of five factors based on Industry 4.0 principles.

Read MoreA Review of High-Productivity Workholding Solutions

Insights on workpiece stabilization and non-traditional fixturing with an emphasis on modern-day solutions.

Read More