Workforce Development

Ed/Training - Invest in Employees to Become Globally Competitive

Coaching, leadership and mentoring should be considered for every individual in order to share in developing the company's strategic mission.

Read MoreSPECIAL FEATURE: Education/Training - Educational Assistance Programs

Current scholarships, certificates, awards, apprenticeships and competitions that provide financial assistance.

Read MoreSPECIAL FEATURE: Education/Training - Evaluating a First-Rate Continuing Education Program

Before individuals or companies begin workforce education, there are several questions that need to be answered.

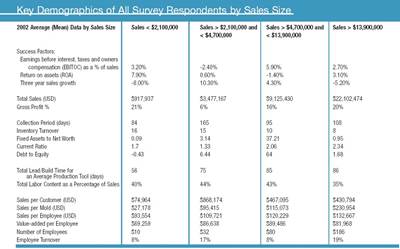

Read MoreThe Law of Averages

MoldMaking Technology's 2003 and 2004 Leadtime Leaders discuss the average age of their employees and how this reflects on the industry's future.

Read MoreSPECIAL FEATURE: Education/Training - Assessing the Value of Training

For the U.S. to compete globally, it is essential to train the moldmaking workforce in its skill and technology.

Read MoreSPECIAL FEATURE: Education/Training - Tailored Training Is the Best Way to Build Effective Manufacturing Teams

On-the-road training brings together owners, managers, programmers and operators in one classroom to develop a team-building process.

Read MoreMake Way for Change

Moldmakers can increase their chances of success by forming a strategic plan, adapting to industry change and seeking new ways to address growth.

Read MoreJohn Morena: A Patented Success

A pioneer of innovative moldmaking methods, this advocate of moldmaking education has shared the wealth through his books and patents.

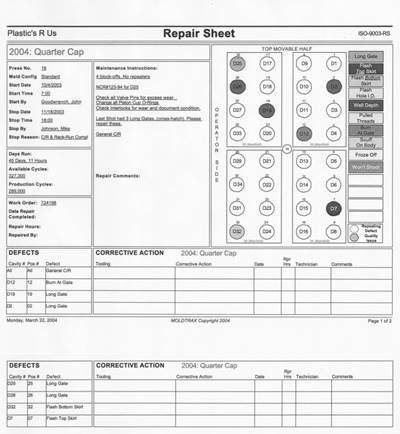

Read MoreAcross the Bench - The Plan Comes Together

The repair sheet is critical to the success of any mold repair plan.

Read MorePart Two of a Two-Part Series Defining and Developing a Training System that Works

To build an effective training system shops must take into consideration management and employees' technical skills.

Read More