Workforce Development

Minnesota Mold & Engineering Group: Strength In Numbers

Four companies unite-serving as a one-stop powerhouse for art to part and anything in-between.

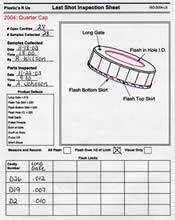

Read MoreAcross the Bench - Creating a Repair Plan

The last shot is the most important key to insuring accurate mold repair.

Read MorePart One of a Two-Part Series Motivating and Training Your Employees

Trust, knowledge and technical training help to motivate employees and guarantee your shop's success.

Read MoreLeadtime Leader Q&A: Show Time

MoldMaking Technology's 2003 and 2004 Leadtime Leaders gear up for the 2004 trade show season and tout the benefits of attending industry expos.

Read MoreThe RP Education Problem

Lack of awareness and education is impeding the growth and expansion of the rapid prototyping industry.

Read MoreEducating Employees

After receiving a financial education, moldmaking employees have greater confidence that they are making the right decisions resulting in improved work performance.

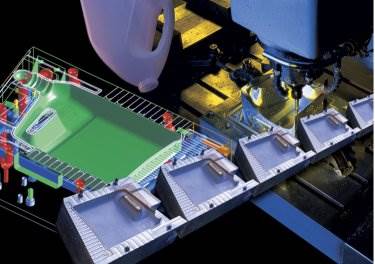

Read MoreTechnology and Skill Are Keys to Mold Shop Success

In a driven and changing mold industry, a secret weapon has helped one mold shop to excel and grow.

Read MoreBill Matteson: Climbing the Moldmaking Ladder

A long and diverse career takes this industry veteran from the shop floor to the classroom.

Read MoreSummit Mold: Better Not Bigger

Using the latest technology and a team effort approach yields sales aplenty-and an Honorable Mention in MoldMaking Technology magazine's Leadtime Leader competition.

Read MoreCentury Die: Forging Ahead

Manufacturing blow molds has kept this moldmaker in the black for more than fifty years-and has earned them an Honorable Mention in MoldMaking Technology magazine's Leadtime Leader competition.

Read More