Surface Treatment

A Look at Mold Texturing

Laser texturing, if understood and appreciated, can open up the door to endless possibilities in texturing, according to this texture house.

Read MoreAutomated Polishing: Commonly Asked Questions about Peening

Peening itself is not a new treatment, but that doesn’t mean it is fully understood. Peening is the process of working a metal's surface to improve its material properties, using mechanical means, such as hammering, blasting with shots (shot peening) or blasting of light beams (laser peening). Here are some commonly asked questions regarding the process.

Read MoreAbrasive Strips Have Strong Adhesive Backing

Adhesive backing on abrasive strips from Boride tolerate wet applications.

Read MoreMMT Memories: A Moldmaker Centerfold

MoldMaking Technology’s 20th anniversary brings back an abundance of memories, including this 1999 feature about Harry Raimondi of (then) Bales Mold Service, a moldmaker “centerfold.”

Read MoreDiamond Compound Line Expands to Suit Variety of Polishing Needs

Boride Engineered Abrasives expanded its Mold Makers Diamond line of diamond compounds with options that are water and oil soluble.

Read MoreTechnology Showcase: More Case Studies for Moldmaking

This week’s Tech Showcase brings yet more case studies featuring the practical application of products for moldmaking.

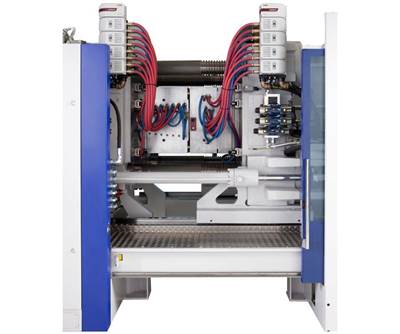

Read MoreInternational Perspective: The Electrochemical Mold Polishing Advantage

This process is said to reduce surface roughness caused by porosity, micro-cracks and the EDM recast layer by as much as seven times.

Read MoreSLIDESHOW: Technology Showcase, Amerimold Product Showcase

This is our industry’s show, and this week we bring you yet more previews of what you can expect to find as you walk the aisles of the biggest Amerimold Expo yet.

Read MoreTechnology Tuesday – Amerimold 2017 Preview

Amerimold 2017 is only six weeks away, and it’s shaping up to be our largest Expo just for the moldmaking industry yet. Here's a preview of a few products and services you can expect to see there.

Read MoreSolving the Part-Sticking Challenge

Low-surface-energy mold coatings can eliminate part sticking, reduce cycle time and increase mold life.

Read More