Sustainability

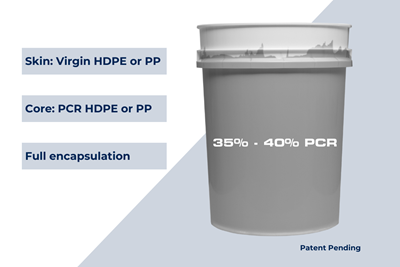

Co-Injection Mold Design Blends PP and PCR Materials

NPE2024: Co-injection mold technology by Top Grade Molds promotes environmental sustainability, without compromising quality or performance.

Read MoreInjection Molds and Integrated Solutions Through Ambition and Innovation

Jordan Robertson, VP, Business Development and Marketing for StackTeck discusses various mold technologies to improve efficiencies in automation, cooling, lightweighting and sustainability.

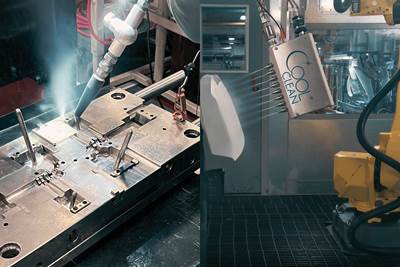

WatchCO2 Cleaning Effectively Generates Contamination-Free Mold Surfaces

NPE2024: Cool Clean Technologies offers dry ice blasting and CO2 snow cleaning methods for more sustainable, no-touch surface preparation and plastics deburring.

Read MoreImpacts of Auto’s Switch to Sustainability

Not only is the auto industry transitioning to electrification but there are concerted efforts to modify the materials used, especially polymers, for interior applications.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreTight-Tolerance, 100% Recyclable Steel Plate Processing

Steel 21 strives to make mold builders more efficient with flat, parallel and more sustainable steel plate grades for plastic injection and compression molds.

Read MoreEmbracing ESG: One Mold Builder's Path to Sustainability and Success

The story of how a company in the moldmaking, injection molding and metal parts industry is navigating the challenges and opportunities associated with sustainability.

Read MorePerspectives on Sustainability in Mold Building: A Diverse Outlook

In conversations with individuals involved in the mold building industry, a variety of perspectives on sustainability emerged, showcasing the multifaceted nature of the term.

Read MoreInnovative Mold Building Enhances Packaging Material Efficiency, Elevates Recyclable Design

A manufacturing-focused design and optimized tooling enhance material efficiency in packaging for a new medical instrument.

Read More