CO2 Cleaning Effectively Generates Contamination-Free Mold Surfaces

NPE2024: Cool Clean Technologies offers dry ice blasting and CO2 snow cleaning methods for more sustainable, no-touch surface preparation and plastics deburring.

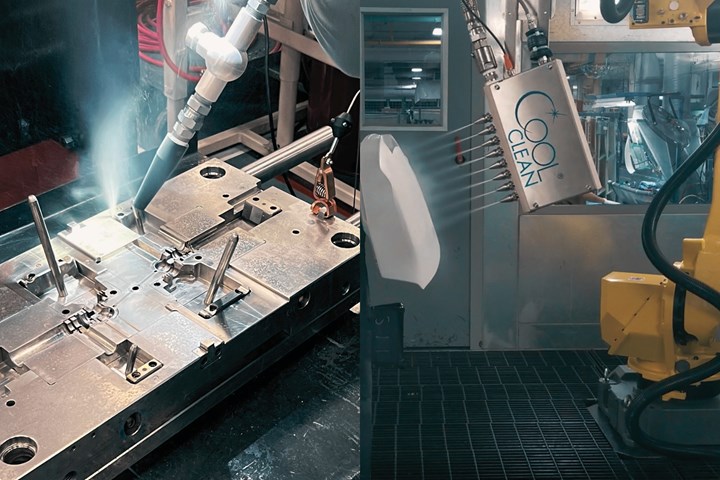

Cool Clean Technologies is highlighting its specialization in CO2 cleaning. The company’s spray-based products incorporate CO2 in all phases for cleaning, surface preparation and plastics deburring, removing contamination from a wide range of surfaces. Its CO2 spray methods can be configured in two ways: dry ice blasting and CO2 snow cleaning.

Dry ice blasting is a fast and effective cleaning solution that surpasses traditional methods for plastic and rubber molds. Dry ice blasting is an aggressive form of cleaning using dry ice pellets, referred to as “blasting rice.” When pellets of dry ice are propelled at high speeds and impact the mold, they sublimate immediately, transferring kinetic energy to the surface and removing any existing debris.

Alternately, CO2 snow cleaning generates the cleaning spray by condensing liquid CO2 to solid CO2, or “snow,” inside the spray nozzle assembly. CO2 spray cleaning systems provide cost-effective, no-touch cleaning that can be dropped into existing production lines with a fraction of the footprint of water-based cleaning. Further, CO2 cleaning is easily automated for surface preparation on automotive plastics.

Importantly, Cool Clean Technologies says there is no waste disposal required when using these solutions, as there are no byproducts, spent solvents or water used in the process. Moreover, the CO2 the company uses is recycled CO2 captured from industrial processes and therefore does not create additional greenhouse gases

Related Content

-

Innovative Mold Building Enhances Packaging Material Efficiency, Elevates Recyclable Design

A manufacturing-focused design and optimized tooling enhance material efficiency in packaging for a new medical instrument.

-

Internal and External Factors Continue to Impact U.S. Moldmaking

Sustainable growth remains in the forecast as economic conditions continue to progress.

-

MMT Chats: Project Engineer Applies Lean Manufacturing Principles to Growing Sustainability Role

MoldMaking Technology Editorial Director Christina Fuges catches up with MMT’s 30-Under-30 Honoree Katherine Pistorius, who has added Regional Sustainability Coordinator alongside her Project Engineer duties, which demonstrates the many paths one can take in a manufacturing career. Here she shares how this opportunity unfolded for her and what the job entails today and in the future. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.