Impacts of Auto’s Switch to Sustainability

Not only is the auto industry transitioning to electrification but there are concerted efforts to modify the materials used, especially polymers, for interior applications.

Tesla has had multiple effects on auto manufacturing, including in the interior, where the traditional knobs and buttons have been eliminated, as in this Model 3. Photo Credit: Tesla

If you look at the dashboard of a Tesla Model 3 the notable thing is something that isn’t there. As in the array of buttons, knobs and switches that have historically be part of the HVAC and infotainment controls for a vehicle. All of those things are typically injection molded. But they are gone. Manufacturing consultant Laurie Harbour, who specializes in automotive, points out that Tesla’s elimination of these comparatively small components has a big impact on moldmakers and molders, especially given that other vehicle manufacturers are following Tesla’s lead.

And there is another thing to notice about that Model 3 (or Model Y or other models) No leather. Well, there is what’s referred to as “vegan leather.” But it is actually a vinyl.

According to Mike Maddelein, vice president of Engineering, Americas, at Adient, one of the largest automotive seat manufacturers in the world, leather as a seat material, once considered to be premium, is giving way — particularly as the industry transitions to electric vehicles — to vinyl and other plastic materials.

The reason? Sustainability. Maddelein says that both OEMs and customers are interested in sustainable materials in their vehicles.

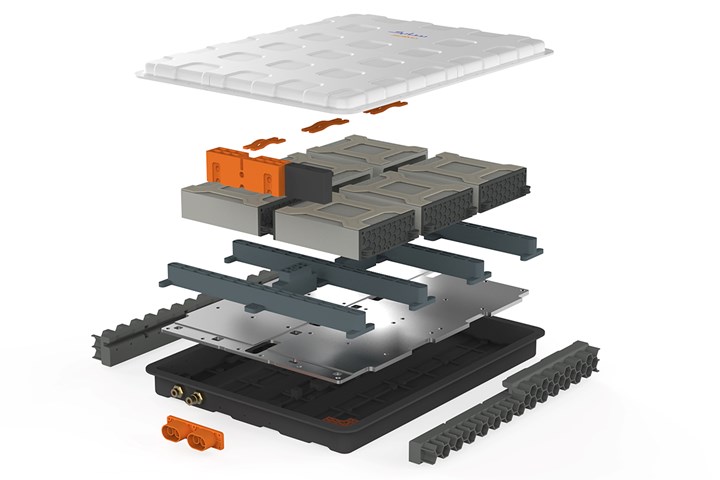

Lithium-ion batteries (shown disassembled here) have two characteristics that plastic materials can help address — they are heavy and they can ignite (the electrolyte is flammable and the oxides within the battery materials provide a steady source of oxygen). Somasekhar Bobba, global technical manager, Mobility, SABIC’s Specialties Business, says they’ve developed an array of thermoplastic resins, compounds and copolymers for EV battery applications. Its NORYL resins, for example, provide light weight, impact resistance and flame retardance. He cited the battery pack cover, side impact absorbers (overmolded onto the metal structure, but providing a 60% weight-save compared with multipart metal reinforcements), corner support plates for the bottom of the battery pack and the bottom of the battery pack itself. Photo Credit: SABIC

Lots of Recycled Plastics

While the attention in the auto industry seems to be all about lithium for batteries, there is a huge effort underway to use materials — many of which are polymers — that support sustainability.

Consider, for example, what General Motors said in its “2022 Sustainability Report” about its use of recycled plastic for its vehicles.

It used recycled plastics in these applications:

- 12.6 million lbs — wheelhouse liners

- 4.5 million lbs — HVAC ducts

- 1.8 million lbs — center console

- 1.5 million lbs — interior door skin

- 1.3 million lbs — window support brackets

- 900,000 lbs — door trim

- 632,000 lbs — underbody shields

- 250,000 lbs — active grill shutters

- 245,000 lbs — hubcaps

- 210,000 lbs — horn housings

- 165,000 lbs — fans and fan shrouds

The point is: Although there is the elimination of some plastic components (Tesla and others got rid of those buttons because it was able to include the functionality in the center screen, which also has the benefits of simplifying inventory and reducing manufacturing complexity), there is also the increase in the use of plastics — but not necessarily the virgin material that has long been characteristic of vehicle interiors.

Euro Regulations

In fact, in Europe this past July, the European Parliament laid out its proposal for handling materials from end-of-life vehicles (ELVs), including plastics, as it calculates that the auto industry accounts for 10% of the overall consumption of the material in Europe. Its “preferred option is to set a medium level of ambition with target for recycled plastics content of 25% by 2030, of which 25% from closed loop ELV treatment.”

Although there are certainly efforts underway to use recycled plastics in vehicles, many of these plastics are sourced from things that didn’t used to be cars or trucks (aka, ELVs).

Because electric vehicles don’t have engines under their hoods, many OEMs are making use of that space for front trunks, or “frunks,” such as this Ford Mustang Mach-E. Its frunk is molded, in part, with recycled yogurt cups. Photo Credit: Ford Motor Co.

Award-Winning Frunk

Consider, for example, the “frunk” (front trunk) insert developed for the Ford Mustang Mach-E electric vehicle, which received a sustainability award from the Society of Plastics Engineers last fall. The frunk is described by Ford as being created from “recycled packaging including and weighing the approximate equivalent of 115 postconsumer-use yogurt cups.” Of this application, Cynthia Williams, global director of sustainability, homologation and compliance at Ford, says, “Our aspiration is to use only recycled or renewable plastic content in our vehicles, and this innovation helps bring us closer to that goal.”

The Volvo EV30 small-electric SUV is claimed by the company to be the most sustainable vehicle it has built. Materials for molding interior trim include recycled window frames. Photo Credit: Volvo

Volvo is launching a new compact electric SUV, the EX30, which includes interior trim made from recycled plastic from old window frames and roller shutters. Customers can select seats covered with “Nordico,” textile that is based, in part, on recycled PET bottles. Or there’s a wool blend, that includes 70% recycled polyester. This use of recycled materials is something that Volvo is promoting, not hiding, describing the EX30 as having lowest carbon footprint of any Volvo made to date. And, like the aforementioned Teslas, the EX30 eliminates knobs and buttons and provides a 12.3-inch screen through which adjustments can be made.

Renault’s Commitments

Presumably because of the current regulations as well as those that are likely to be enacted, other European OEMs are focusing efforts on the use of sustainable materials. For example, Renault just launched the Scenic E-Tech EV. About it, Cléa Martinet, vice president, Sustainability, Renault Group, says, “This is the first time we built in commitments relating to sustainability and decarbonization from cradle to grave, even from cradle to cradle.”

So, for example, 80% of the dash structure is made of recycled polypropylene; 97% of the carpets and 99.5% of the headliner is produced with material made from recycled bottles — polyethylene terephthalate (PET).

And, while there may have been the case that the use of recycled polymers in vehicle applications that are visible to the consumer (after all, wheelhouse liners and HVAC ducts aren’t the sort of things that people pay attention to) were suboptimal, Gilles Vidal, vice president of Design at Renault, noted, “Yes, electric vehicles can be desirable and sustainable at the same time. It’s a noble approach to make a product that is useful, practical for daily life and on top of which is recyclable and sustainable.”

Part of the 55-ton haul of waste plastics recovered last fall from the Pacific Ocean by Kia partner Ocean Cleanup. Kia is committed to using materials like these for its vehicles as it works toward being carbon-neutral. Photo Credit: Kia

Kia Goes Deep

One automotive company that is really committed to the use of sustainable materials in its vehicles is Kia. Last fall, Kia’s partner, The Ocean Cleanup, recovered 55 tons of plastics from the Pacific Ocean. Kia plans to use some of those materials in future models, which is in line with what it is doing at present.

The company has identified 10 “must-have sustainability items” that it will deploy in all of its vehicles going forward, starting with the award-winning, three-row electric SUV, the 2024 EV9. These are:

- Bioplastics. Based on various biomass materials (for example, vegetable oils, corn extract, sawdust, sugarcane). Used in interior trim.

- Postconsumer material (PCM) plastic. Recycled material. Used for EV9 door garnish.

- Bio Polyurethane. The leather alternative. Incorporates plant-based material.

- Recycled PET. Used for fabric applications. Going beyond other recycled PET materials, Kia is also using recycled yarn in the fabric. Overall, more than 70 recycled PET bottles are used in the EV9.

- Recycled PET carpet. The standard carpets in the EV9 are 100% recycled PET. A portion of the materials are from fishing nets captured by the Ocean Cleanup efforts.

- Bio Polyurethane foam. Used for the headrests.

- Bio paint. Made with rapeseed oil. Used on the door window switch panels.

- BTX-free paint. No benzene, toluene and xylene (BTX) is used in the formulation. Used for the interior trim (except for the aforementioned door window switch panels).

- Recycled PET yarn. Used for seat stitching.

- Recycled PET felt. Used for sound-attenuation applications in the interior.

Kia calculates that the components in the EV9 made from recycled plastic and bio-based materials weigh approximately 34 kg.

And Kia is going even further in its pursuit of sustainable materials. Last fall it revealed a concept vehicle, the Kia Concept EV3, which features a table in the cabin. It is fabricated with mycelium, about which Marilia Biill, head of CMF Design at Kia, says, “Mycelium, which comes from mushroom roots, combines excellent strength with an extremely soft surface. Developing grown materials, a process referred to as bio fabrication, is a major goal for Kia. Using Mycelium enables us to mimic the processes we see in nature and leverage it to design more sustainable solutions — the material can be grown in any shape you want using a mold.”

That’s right: growing substrate materials in a mold.

Related Content

Dynamic Tool Corp. Wins MoldMaking Technology’s 2024 Leadtime Leader Award

Dynamic Tool Corp., a provider of engineered tooling solutions based in Menomonee, Wisconsin, has been awarded MoldMaking Technology’s prestigious 2024 Leadtime Leader Award. The announcement was made during a live awards ceremony at the Plastics Technology booth, where owners Steve and Ken Eberle accepted the award on behalf of their team.

Read MoreAdvancing Moldmaking and Plastics: Trends in 3D Printing, Automation and Sustainability

NPE 2024 showcased the latest trends and technologies in innovation, efficiency and sustainability for moldmakers and molders, featuring advancements in 3D printing, automation, design and virtual reality/augmented reality/artificial intelligence.

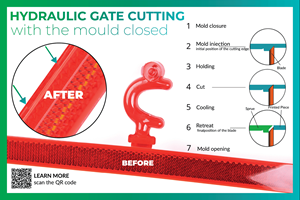

Read MoreHydraulic Gating Cutting Reliably Separates Molded Parts

NPE2024: Material displacement technology offered by Ermanno Balzi Srl enables precise separation of the molded part from the gate during the molding cycle.

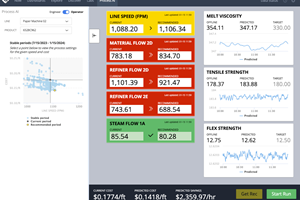

Read MoreUse AI, Machine Learning to Take Variability Out of Manufacturing

Variability has always created insurmountable challenges for manufacturers. However, in the last decade, impact has been more painful due to a lack of experienced workforce. By leveraging technological advancements, particularly in AI, manufacturers can gain a transformative competitive advantage in both cost reduction and workforce development.

Read MoreRead Next

Readjusting to the New Normal of Automotive Tooling

“Control what you can control,” Laurie Harbour of Harbour Results says because on top of our current economic uncertainty, government volatility, tariffs and trade there also is a shift happening in the automotive industry that demands flexibility from today’s mold builders.

Read MoreSpecialist Automotive Mold Builder Mentors in Work and Life Skills

Southeastern mold builder PFAFF Molds sets the standard in toolmaking for automotive window and vehicle body sealing systems through knowledge-sharing and automation.

Read MoreWhat's So Cool About Manufacturing? Students Use a Camera to Find Out

Neu Dynamics Corp. collaborates with DVIRC, Ignite-MS STEM/Science and the Pennsbury School District to foster an interest in moldmaking and manufacturing among the younger generation through a state-wide student video contest.

Read More

.jpg;width=70;height=70;mode=crop)