NPE

Software Aids Localization of Injection Mold Inventory

NPE2024: Hasco introduces Mould Track for the precise tracking of injection mold inventory for improved production planning.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreCorrosion-Resistant Mold Steel Designed For Polishability

NPE2024: Uddeholm showcases its Tyrax ESR mold steel that combines toughness, corrosion and wear resistance.

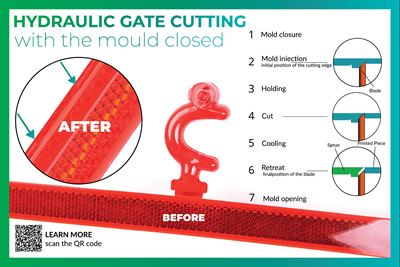

Read MoreHydraulic Gating Cutting Reliably Separates Molded Parts

NPE2024: Material displacement technology offered by Ermanno Balzi Srl enables precise separation of the molded part from the gate during the molding cycle.

Read MoreHot Runners, Auxiliary Injection Units Enhance Control, Processing Capabilities

NPE2024: New hot runner systems, temperature and motion controllers, an auxiliary injection unit, a gate seal and sustainable processing solutions will be displayed at Mold-Master’s booth.

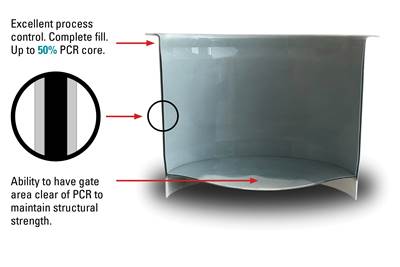

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

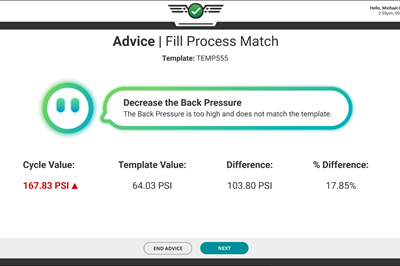

Read MoreSmart Assistant Bridges Injection Molding Skills Gap

NPE2024: MAX the Process Advisor, as well as free presentations and training by RJG Inc.

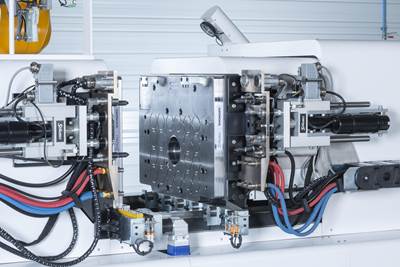

Read MoreMagnetic Mold Clamping Amplifies Quick Mold Changes

NPE2024: Stäubli highlights its adaptable QMC123 technology, which is capable of calculating the clamping force for each mold beforehand, in addition to ensuring worker safety.

Read MoreMold Repair, Design Solutions Serve Many Industries

NPE2024: Adler Industrial Solutions exhibits its selection of Pinnacle Molds and Rapid Mold solutions.

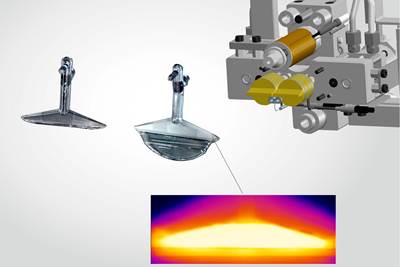

Read MoreLocalized Mold Temperature Control Reduces Knit Lines, Optimizes Melt Flow

NPE2024: Dynamic localized mold temperature control Heat-Inject Technology by Incoe Corp. demonstrates how the part surface quality and the filling of the cavity is optimized with relatively little effort using targeted heat pulses.

Read More