Magnetic Mold Clamping Amplifies Quick Mold Changes

NPE2024: Stäubli highlights its adaptable QMC123 technology, which is capable of calculating the clamping force for each mold beforehand, in addition to ensuring worker safety.

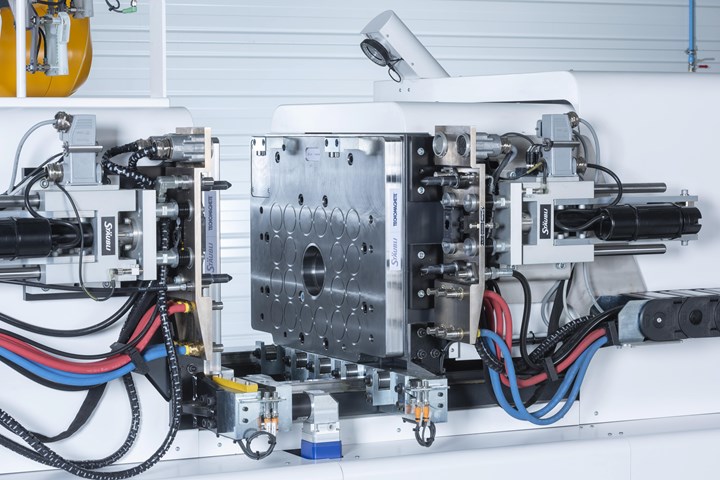

Stäubli Corp. presents the QMC123, released in 2023, as an advanced magnetic mold clamping technology option, distinctive by its magnetic holding force measurement and analysis. It is adapted to the full range of machines and molds. There will be demonstrations of the QMC123 at Stäubli’s booth.

In the new system, the amount of holding force that can be generated can be customized to the mold and its condition. Specifically for mold builders, Stäubli’s IMAG-Editor software is available to calculate the expected magnetic holding force that can be generated with each mold, based on CAD data, during the mold design phase, reducing potential machine downtime and issues during production.

Offering a high level of safety, Stäubli says that its magnetic mold clamping system anticipates malfunctions, not only protecting employees and equipment but also improving mold quality, increasing productivity and providing cost savings. For example, its interactive control panel enables validation of safety points during mold changing operations. Via IMAG, the operator is alerted if the mold clamping system is damaged or insufficient with regard to the force exerted on the mold.

In addition to these displays, there will be Stäubli’s range of quick mold change solutions including: mono couplings, a mold loading vehicle, automatic multi-connection system, a robot with an automatic toolchanger and more.

Related Content

-

Plastic Injection Molder Debuts EOAT, Mold Monitoring Solutions

NPE2024: Exhibiting for the first time, European-based Mouldpro ApS highlights new solutions — the Roborex and Flosense — alongside partner Globeius.

-

Mold Slides, Traceability Device Save Space and Streamline Production

NPE2024: CUMSA is offering attendees a look at the Long Stroke Slide and its In-Mold Traceability technology, designed to provide more reliable and readable traceability on molded parts.

-

Moldmaker Highlights Domestic Mold Expertise for Plastics Industry

MSI Mold Builders has the ability to develop a full range of injection molds and structural foam molds domestically, meeting the needs of U.S.-based molders.

.jpg;maxWidth=300;quality=90)