Localized Mold Temperature Control Reduces Knit Lines, Optimizes Melt Flow

NPE2024: Dynamic localized mold temperature control Heat-Inject Technology by Incoe Corp. demonstrates how the part surface quality and the filling of the cavity is optimized with relatively little effort using targeted heat pulses.

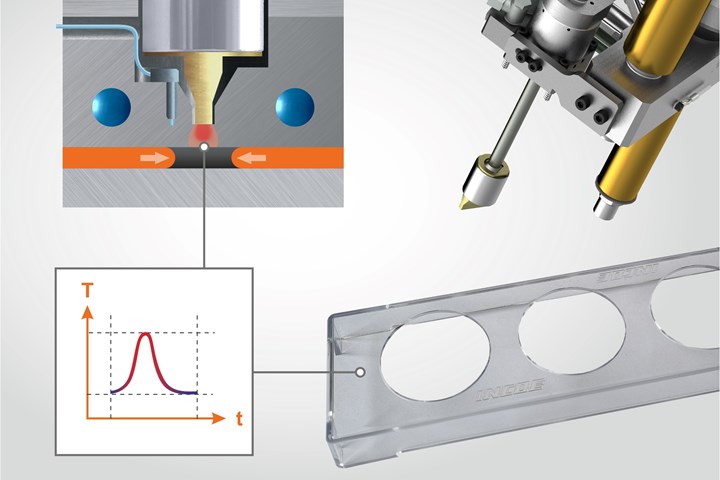

Fig. 1: Unitized with the hot runner, heat pulses are transferred into the cavity wall to avoid the knit line where the melt flows merge. Source, all images: Incoe Corp.

Incoe Corp. introduces Heat-Inject technology, a solution for reducing knit lines about holes and openings on a part, and improving melt flow through cold runner fan gates or thin-wall sections of the cavity. Heat-Inject technology is designed as an add-on module to Incoe unitized manifold systems, offering a simple design and implementation, reduced mold modifications/costs compared to other solutions and low power consumption — only 220VAC/30-amp power input is required.

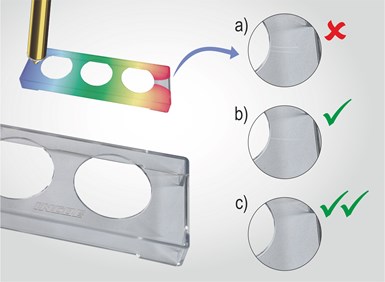

Fig 2: Solving knit line issues with Heat-Inject: (a) knit lines occur when two melt flows merge, (b) the knit disappears on the surface heated with Heat-Inject and (c) no knit lines visible when both sides are heated.

Heat-Inject technology is based on the DH system from partner company Hotset. The technology’s localized selection of dynamic mold temperature control ensures significantly improved part quality and low-stress filling of the cavity, Incoe reports. How knit lines can be eliminated will be shown at its booth using a hot runner mold equipped with Heat-Inject technology. Incoe’s Flight Attendant will be molded using an all-electric LSG-240 E LS Mtron machine and Sepro Robot cell. The three holes in one of the Flight Attendant’s transparent components will demonstrate the Heat-inject technology solution (see Fig. 2).

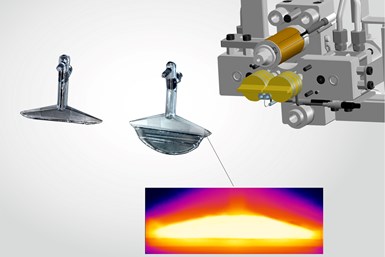

Fig 3: The melt flow through a fan gate was improved using the Incoe Heat-Inject technology. Resulting improved part quality and significant reduction of scrap.

Troubleshooting during the production of a control panel for a premium household appliance further highlights additional benefit of this technology, namely applying heat pulses to improve melt flow and cavity filling. After various defects on some parts occurred, the manufacturer of the panel decided to perform a test using Incoe’s Heat-inject technology. The concept: Heat the fan gate feeding the cavity to improve the melt flow.

During the production of the molded part using Heat-Inject, it became apparent that heating the fan gate to improve cavity filling had been correct. The filling study during sampling and the thermographic image indicated that the fan gate was heated uniformly when the heat pulse was applied (Fig. 3). This improved the molded parts, which no longer showed surface defects.

Related Content

-

Use AI, Machine Learning to Take Variability Out of Manufacturing

Variability has always created insurmountable challenges for manufacturers. However, in the last decade, impact has been more painful due to a lack of experienced workforce. By leveraging technological advancements, particularly in AI, manufacturers can gain a transformative competitive advantage in both cost reduction and workforce development.

-

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

-

Unveiling the Future: Dive Into NPE2024's Moldmaking Marvels

Get ready for the ultimate moldmaking extravaganza! Explore exclusive previews of cutting-edge technologies and solutions shaping the industry at NPE: The Plastics Show.