Mold Preservation and Maintenance for Ultimate Productivity

Making a mold last with as little downtime as possible is the ultimate goal of a plastic molding manager. By taking some early, preventive steps, moldmakers can extend the life of the mold and save money in the long run.

Technological advances have played a definite role in this industry, producing some very innovative and effective materials that can promote the preservation of molds. Then again, some old standards are still very effective. What you choose to do depends on the materials being molded. Either way, each of the techniques in this article will help to obtain optimum protection and long life for the molds that you have in production. In addition to all of the above, you'll see how you can establish a preventive maintenance program that will help you monitor wear in your molds.

First, it must be said that working with a knowledgeable, skilled plating and polishing company is the first step toward properly preserving your tooling. If your vendor doesn't know his craft, lost time and productivity will undoubtedly take their toll, decreasing profits and, perhaps, losing your customers in the long run.

Old Methods Still Do the Job

As stated previously, some tried and true methods of preserving molds still work. One of these is hard chrome (see Figure 1). A good example of its effectiveness is illustrated with electrical/circuit breaker molds. Typically, these breaker molds require plastic materials that are as much as 40 percent glass-filled - which can erode and severely damage gate and surrounding areas. To help combat wear, using a high diamond polish and a coating of hard chrome is recommended.

Using only the purest form of hard chrome on your tooling allows you to maintain and mimic any S.P.I. finish. Chrome has a hardness rating of 72 Rockwell and is applied at the low temperature of 130xF. Combine this with a good preventive maintenance program and you can ensure lasting durability and superior abrasion resistance against phenolic, mineral or glass-filled resins (see Figure 2). Use hard chrome as your wear indicator of when maintenance is needed. For example, wear in and around gate areas plated with hard chrome is the first sign that your mold needs servicing. Hard chrome also promotes excellent release of parts. If you are running gaseous materials such as Polyvinylchloride (PVC) or fire retardant materials, many times they will produce an orange-colored rust - corroding the mold almost while you are watching. When molding products as smoke detectors and insulating panels used in electrical parts, mold corrosion is a factor. This problem also occurs in more critical environments - for example, with customers that mold parts used in the medical industry where oxidation cannot be tolerated and sterilization is of utmost importance. Here, electroless nickel is your preservation solution.

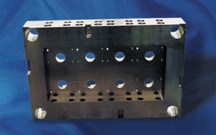

Electroless nickel provides excellent resistance to oxidation (see Figure 3). Unlike hard chrome, it plates very uniformly in thin deposits of .0002"-.0003". Even in tight areas of detailed parts, electroless nickel, at a 50 RC hardness, is ideal for corrosion protection. It can be used for build-ups in very accurate deposits of .002"-.003" and is easily machined. It also can be used as a dimensional build-up under a flash chrome. Use electroless nickel for sizing threaded cores and inserts or for reducing or enlarging cavities and cores. You also can use it on entire mold bases, A & B plates, ejector base housings, pin plates and pillar supports for years of low-maintenance and rust-free operation.

Newer Methods Take Preservation to a Higher Level

As molding materials become more diverse and molds more complex, it becomes necessary to develop more diverse forms of mold coatings that can handle the various challenges put forth in order to facilitate optimum performance from the mold.

For example, if you are molding highly intricate parts using glass-filled materials, it becomes necessary to protect your mold from both corrosion and abrasion using a coating that can plate uniformly in detailed areas like ribs and bosses. Commonly molded parts included in this category are recessed ceiling light baffles and many outdoor products that are exposed to the elements. How do you preserve the mold's integrity for trouble-free performance? For less detailed parts, hard chrome would most likely be used, but, as noted above, hard chrome does not handle multifaceted surfaces very well. Instead, there is a nickel-cobalt composite coating (see Figure 4).

Developed for this very purpose, this coating can be an economical alternative to hard chrome. Hard chrome requires construction of a conforming anode to coat the mold. The more detail in the mold, the more time it takes to build the anode and the more expensive the process becomes. This nickel-cobalt composite coating requires no anode, and because of the nickel content, it plates much more uniformly. The cobalt gives it its great abrasion resistance and the protection needed to keep running the mold with fewer maintenance checks.

For high wear molding processes, and in particular those with intricate details, a new product called diamond-chrome works very well for preserving molds (see Figure 5). Diamond-chrome is a versatile, hard coating with a Rockwell hardness rating in the high 80s. It can plate heat-treated or regular steel - and any other metal, such as aluminum, beryllium, copper, brass, stainless, cold-rolled and more. It outperforms titanium nitride coating because it plates at a very low temperature (about 130xF), while titanium nitride requires higher, more limiting temperatures of 800xF or higher. Diamond-chrome won't compromise the dimensional integrity of the plated tool, no matter the size or shape. Molders have found unmatched success using diamond-chrome in cores, cavities, slides, ejector sleeves and custom mold components that require extended life, such as rotating and unscrewing cores.

Adding to the versatility of diamond-chrome is the fact that it is very strippable, having no effect on the base material, so when maintenance is needed, the process goes fairly quickly and can save money. Plus, diamond-chrome can be deposited at any thickness and in controlled deposits ranging from 20 millionths of an inch to one thousandth of an inch. Titanium nitride is generally only available in thin deposits of millionths of an inch. Diamond-chrome has the ability to coat complex details, while titanium nitride has very limited coverage of complex details. Diamond-chrome is an excellent choice for mold preservation and durability.

Preventive Maintenance is the Key

It is good policy to set up a preventive maintenance program in your shop to help you effectively determine when your molds need to be re-plated. Implementing a preventive maintenance program will absolutely help save you time and money if you educate your personnel on how to monitor molds during production.

There are a couple of ways to do this, but the most efficient is to use your plating material as your gauge. Whether you are using hard chrome, nickel, diamond-chrome, nickel-cobalt or any other coating, educate yourself and your employees about how to tell when the coating is showing wear. When it begins to wear down, especially in high-wear areas such as gates and runners, it's time to send the mold back to your plating house to get it refurbished.

It cannot be stressed enough that to be effective with your preventive maintenance program, you have to pull your mold for re-plating before it wears through. If you let it wear completely through it will require more polishing and additional expense. The reason is due to the difference between chrome and steel. Chrome is approximately 20 Rockwell points harder than the base steel, so exposed steel will wear much faster than the coated surfaces surrounding it, causing deeper holes that require more in-depth re-polishing.

How do you know it's wearing through? The best way to tell is by using a thickness gauge tester. When the mold first arrives in your plant, take the time to measure the surface thickness using this specialized tool. Measure the high wear areas especially. As you run production on the mold, occasionally pause to re-measure those areas. When you have determined that the finish is wearing to a critical level, pull it and send it out for maintenance.

Also, establish a part count program. This is especially effective with long-running molds. Keep an accurate count of the number of parts you get from the time you first run the mold until it is ready for its first maintenance work. That count will now act as a gauge for when the next maintenance work is due. Because you know approximately when the mold will be ready for re-plating, you can set up an appointment with your plating vendor, giving him ample time to schedule you in and allowing you to optimize the use of the mold and the machine that's running it. In addition, you can also prearrange your employees' work schedule so that their time is maximized while the mold is out. There's no question that a part count program - in tandem with a preventive maintenance program - makes for a highly efficient use of all your resources.

In closing, think of mold coatings and a preventive maintenance program as an insurance policy for your molds. It will keep your jobs running efficiently and eliminate unexpected delays and expenses - benefits that you and your customers will appreciate.

Related Content

What Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

Read MorePrecision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

Read More5 Hot Runner Tips for Moldmakers and Molders

Best practices for initial hot runner tryouts and effective preventive maintenance.

Read MoreWhat You Should Know About Injection Mold Safety Straps

Every mold should have one in order to be safe and OSHA compliant.

Read MoreRead Next

Surface Finish: Understanding Mold Surface Lingo

The correlation between the units of measure used to define mold surfaces is a commonly raised question. This article will lay these units of measure side by side in a conversion format so that companies can confidently understand with what they are dealing.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More