Leadership

Additive Manufacturing Users Group Accepting Scholarship Applications

The Additive Manufacturing Users Group (AMUG) announced that it is accepting applications for two scholarships for additive manufacturing and 3D printing education and professional development, which will be awarded at its annual conference.

Read MoreReshoring Remains Strong in 2015

About 200,000 manufacturing jobs have been brought to the U.S. from offshore in the last six years, according to Reshoring Initiative calculations. That gain is the result of both new reshoring and Foreign Direct Investment (FDI) in our manufacturing sector. However, there has been some negative news about reshoring recently that Harry Moser founder and president of the Reshoring Initiative wants to address.

Read MoreNIMS Credentials Help Lead Next Gen Workforce Development

Maintaining national industry standards inside the classroom is no easy task but the faculty and staff of Eastern Westmoreland Career and Technology Center once again rose to the challenge and officially renewed the national accreditation of the Machine Tool Technology program.

Read MoreNew Year, New Opportunities to Advance

Happy New Year! It’s January 2016 and that means there’s a whole new year ahead of us that’s filled with new opportunities to advance company goals and profitability.

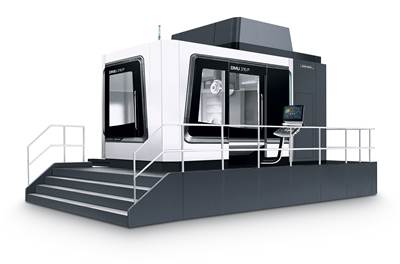

Read MoreInto the New Year of Trade Fairs with Answers to the Question of Digitization and 6 World Premieres

By beginning of the year, DMG MORI will once again underline its high level of innovation at the Open House at DECKEL MAHO in Pfronten.

Read MoreThe Commitment Challenge

I want to encourage (and challenge) our readers to commit locally to recruiting our next generation of workers. We all need to do our part, and sometimes it actually only takes a small investment to make a big impact. Here's one example.

Read MoreIsn't It Time You Dare to Lead?

It’s been said that true leaders don’t create followers, they create more leaders. That is the result we are looking to achieve through our Leadtime Leader Awards competition. Nominate your shop today!

Read MoreThe Who and the What of the Right Shop Culture

Tune in to hear about a proven business strategy for creating a continuous improvement environment that has set this mold manufacturer apart from its competition. You'll also hear the personal journeys of a few employees and you'll get a look at a business case presenting actual data on the impact of this strategy on the company.

Read MoreDare to Lead

What does it mean to be a Leadtime Leader? It means setting a higher standard for overall innovation, efficiency, quality and commitment in mold manufacturing.

WatchFast-Track Training

Right Skills Now focuses on in-demand skills in CNC operations, programming and machining, which will account for 14 to 22 percent of job growth by 2024, according to NIMS. Let's take a look at this unique initiative.

Read More

.jpg;maxWidth=400;quality=70)