Leadership

IMTS: From Imagination to Innovation

IMTS is here, and I had the opportunity to preview some pretty cool exhibits yesterday along with other members of the press.

Read MoreMold Builder on a Mission

Not only is Westminster Tool a mold builder on a mission to improve the manufacturing path to success through collaboration with a local manufacturing association, schools and local government, but it is also a group of people on a mission to help our wounded warriors, and they invite you to do the same.

Read MoreForecasting and Balancing Business

Aligning operations, sales and business is essential to leveling out the effects of peaks and valleys.

Read MoreMMT's August IMTS Digital Edition Is Available

This month, along with an IMTS Exhibitor Product Showcase, we take a look at a variety of cutting tool, machining, inspection and measurement, advanced manufacturing and workforce development challenges and solutions.

Read MoreRemaining in the Moldmaking Game

The Portuguese moldmaking industy has had its ups and downs over the past four decades, but remains in the game. Today it is on the list of advanced European economies and has continued to improve its capabilites and stay current with technology. I caught up with Moldetipo Group's business development manager for an update on the current state of moldmaking in Portugal.

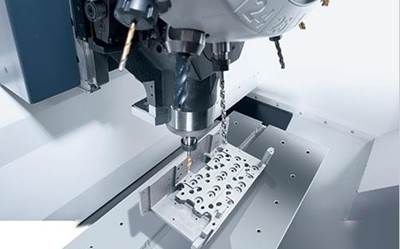

Read MoreMilling in Slow Motion

Rough milling operations can take hours on large components and typically remove more than half the raw material by volume. Selecting the proper machining method for the component and machine tool creates a successful and stable system. The use of plunge roughing, commonly referred to as plunge milling, has grown recently as cutting tools that can handle the tough requirements of this machining method have become more readily available.

WatchStrategic Machining

Combining what they know with what they have allows these makers of investment casting molds to optimize the cutting of complex contours.

Read MoreUsing CAD/CAM for Product Development

To show the value of CAD/CAM software in research and development projects, I wanted to share this story that was sent to me about an Italian plastic injection mold builder that combines craftsmanship with current technologies to offer fully integrated project management.

Read MoreThrowback Thursday: The Multi Approach

I consider myself quite the multitasker. Someone who is able to focus on multiple projects with equal efficiency. Well, most of the time anyway. But when it comes to mold manufacturing, multitasking can take the shop's operations to a whole new level ... every time. This look-back at our archives features an article that breaks down the barriers to multitasking and explains how it can optimize both production and profit in milling and high-speed cutting operations.

Read MoreLeadtime Leaders Made Their Presence Known at Amerimold

The moldmaking community is a family of sorts, and this becomes very evident every year at Amerimold when we celebrate our annual Leadtime Leader Awards Competition. Last week this was taken to another level when 2016 Winner Krieger Craftsmen registered a busload of people to attend Amerimold and make their presence known.

Read More