FAQ

5 Hot Runner Tips for Moldmakers and Molders

Best practices for initial hot runner tryouts and effective preventive maintenance.

Read MoreHow to Solve Hot Runner Challenges When Molding with Bioresins

A review of the considerations and adaptations required to design hot runners and implement highly productive injection molding operations.

Read MoreHow to Overcome Deep-Hole Drilling Obstacles in Mold Machining

Keep up with the newest tooling innovations to overcome holemaking and finishing challenges.

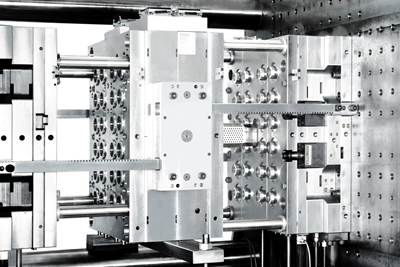

Read MoreWhat You Need to Know About Hot Runner Systems and How to Optimize Their Performance

How to make the most out of the hot runner design, function and performance.

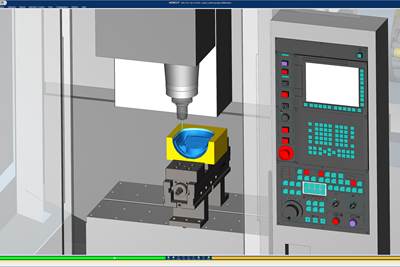

Read MoreHow to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

Read MoreUnderstanding Diamond Compounds

Diamond compounds, with their varied grades, colors and base options, provide a comprehensive solution for mold builders in need of precise and superior polishing across diverse materials and applications.

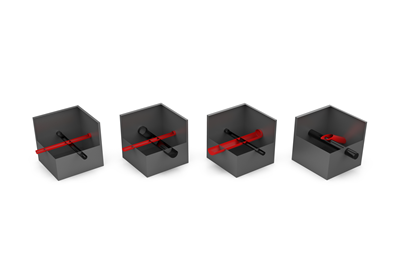

Read MoreTen Things You Need to Know about Circle Segment Milling

Considerations for evaluating if circle segment end mills or conical barrel cutters are right for your mold machining applications.

Read MoreHow to Clean and Maintain Molds With Intricate Conformal Cooling Channels

A water-based, eco-friendly plastic mold cleaning system helps Rankine-Hinman Manufacturing restore flow rates and avoid big-ticket failures on complex and costly molds.

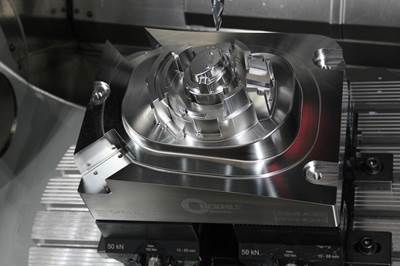

Read MoreHow to Lower Cycle Times With the Right Tool Steel

Combining excellent mechanical properties, high wear resistance and high thermal conductivity in a specialty tool steel yields cycle time reduction.

Read MoreHow a Small Programming Change Cuts Cycle Time in Half

Overriding the CAM system when milling a series of lifter pockets helps to improve metal removal rate and increase feed rates.

Read More