CAD/CAM’s Role in Customer Collaboration

Seven skills—enhanced by the right CAD/CAM solution—that will help you win more business.

Many tool shops claim to be collaborating with their customers. Those that go beyond lip service and take customer collaboration to a new level will tell you the effort is not trivial. With that said, it is also clear that the investment in customer collaboration pays off. With more tool shops across the street and across the pond vying for every job, developing tight working relationships with customers becomes a critical competency that creates barriers to the competition.

Here are seven skills mastered by tool shops that excel in customer collaboration.

1. Understand the Customer’s Business Needs

With a focus on satisfying clients, improving quality, and adapting to change, Curtil / Marland (Pittsfield, MA) is an industry leader in its market. The company’s core business is serving the food & beverage industry, producing high-quality, cost-effective closure molds for more than 50 years. Today, Marland services a variety of industries, including personal care & cosmetics, medical & pharmaceutical, and household & industrial products. Building on its stellar reputation for quality, the company has expanded to serve customers all around the globe, in locations ranging from Australia and Thailand to Argentina and Brazil.

Understanding the unique challenges and needs of their customers sets Marland apart from both overseas and domestic competition. Every customer project starts with the assignment of a team consisting of a Sales Executive, a Design Engineer, and the Manufacturing VP. The mold concept is developed with a balance of cost, performance, and longevity to produce a mold with optimum value to the customer. This hands-on approach ensures customer success and generates substantial repeat business and referrals.

This approach has proven valuable for Marland in keeping up with evolving customer needs. Stephen Renwick of Pano Cap Canada Limited and a Marland customer says, “We recently purchased a mold from Marland that required a tight delivery and higher capacity. They produced a mold with a significant cycle time improvement. The end result is almost double the capacity over our existing workcell while maintaining the same footprint.”

2. Help Customers Make the Right Choices for More Efficient Manufacturing

PTA Corporation (Oxford, CT and Longmont, CO) is known for bringing ideas to reality, collaborating with world-leading companies such as Apple, GE, Philips, Siemens, and Zoll Medical to address all areas of design, quality, cost, and manufacturability. Each client works with a specific team at PTA that takes the product idea through a step-by-step process from design to production and assembly.

“We get involved with projects far before they are ready to be released to manufacturing,” says Rich Dorans, Vice President of Operations at PTA. “Files coming in are often no more than a basic concept. We give our clients suggestions to optimize manufacturability with better part design and material selection, assisting in the selection of different plastic resins, surface finishes, and finish treatments, as well as defining proper draft and other details needed for applying solid tooling concepts.” Adds Don Miller, Senior Mold Designer at PTA: “We emphasize extensive design review and analysis so by the time a project is ready to go it greatly streamlines the rest of the manufacturing process.”

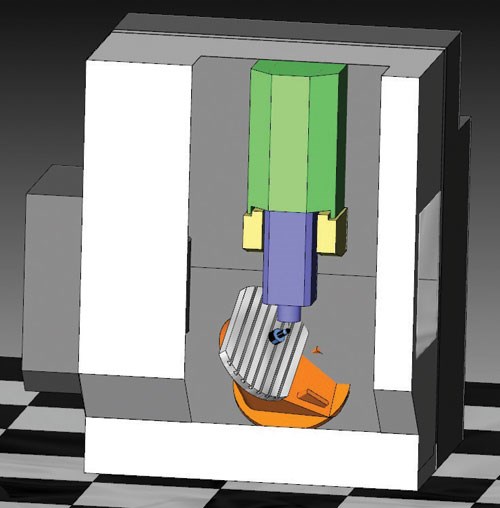

PTA takes advantage of the powerful visualization capabilities of its CAD software to provide customers with comprehensive feedback about any issues that can come up in manufacturing. “We can take parts, run sections through it, see the interferences, and put parts into an assembly to see how they interact with one another so we can quickly let customers know whether they should modify some of the geometry. Our CAD/CAM software has built-in tools that our project managers use to simulate a split of how the part will fit into the tool to analyze drafts before it goes to the designers.”

3. Design Your Processes for Agility

While some tool shops view Engineering Change Orders (ECO) as a nuisance, others see them as an opportunity to stand out. Solo Tool & Mold (Windsor, ON) was founded in 1984 by Franz Reiter, who came from Germany to start his own tooling business with the premise of providing high tolerance, quality tooling to satisfy needs of the most demanding customers.

In the past, every Engineering Change Order (ECO) required manual updating the models and re-issuing the mold design. After revising the process and upgrading its software, dealing with engineering changes has become much easier. “With our new software we are able to go into a mold design, make the part change and that change is associative throughout the software,” explains Bulmer. “We are able to keep the data flow to the electrodes, the wire EDM paths and the CNC paths. The designer does not have to update or redraw that insert or block again. The old process was repetitive and cumbersome. Now when you make a change, everything changes. The savings in time and improved productivity are dramatic.”

4. Provide Visibility to the Customer Throughout the Process

Nortool Precision Machining & Tool (Elkhart, IN) prides itself on providing customers with a complete solution from concept to production, including product and tool design consultation, material selection and manufacturability analysis. Established in 1991 to support Norco’s manufacturing operations, the Nortool division has since expanded to serve a broad range of customers, including some of the leading companies in the automotive industry and other manufacturing sectors. Services provided by Nortool range from prototyping to progressive die design and manufacturing, as well as assembly and welding of machined components and precision machining, including 4-axis machining.

Nortool has recognized the need to help its customers stay in business by providing cost-effective solutions and exceptional speed-to-market. “We are all impacted by overseas competition,” explains Mark Modglin, Nortool’s Brand Manager. “If we can help our customers get their product out the door faster, we are assisting them in keeping an edge over the competition.”

Taking practical steps towards these objectives, Nortool has modified its operational practices, accompanied by a transformation of the technologies used to execute and support the entire design and manufacturing cycle.

Nortool has established an “early involvement” program, which includes an extensive design review and analysis where product ideas are taken step-by-step from CAD design through production and assembly. “As a result of this process, we are able to advise clients how to optimize manufacturability, assist in the selection of finishes, help define proper material thickness, and provide additional suggestions for solid tooling practices,” says Modglin. “The bottom line is that we hold ourselves responsible for ensuring the die we provide is highly robust and will produce high-quality parts.”

“Our customers are benefiting not only from our ability to do things better and faster, but also from having direct visibility into our process. They can look at what we are doing at any stage of the design and manufacturing, see where we are in the process, and provide immediate feedback if needed.”

5. Hire the Right People

Aluminum Injection Mold Company (Rochester, NY) provides creative production aluminum tooling solutions to a wide range of industries including automotive, medical, computer / business machines, telecommunications, and consumer products since 1985.

Unlike most companies that have different people assigned to each task, Aluminum Injection Mold Company (AIM) assigns one moldmaker to handle a single project from start to finish. “Instead of having one person do the design and then hand it off to someone else who is not familiar with it, we’ll have the same person do the mold design and then machine the mold right up to completion,” says Tom Bergman, Vice President of Manufacturing at AIM.

The same employee that built the mold would even go out and sample the mold at the molding machine. “This way each employee has a complete understanding of what they’re building. It gives them a unique perspective that allows them to optimize the design and streamline it for production.”

This multidisciplinary knowledge that every employee holds is extremely valuable to AIM’s customers, as Bergman explains: “We look at the customer CAD file and we can tell them where they might have some trouble in the molding phase, pointing to things such as wall thickness or where they may not have enough draft.”

However, this unique approach requires a special skill set that is not always easy to find. “It’s a little more difficult to find individuals who meet these requirements because we’re looking for people who can perform multiple tasks and take ownership over an entire project,” concurs Bergman.

6. Take Advantage of Technologies that Speed Up Collaboration

Hoosier Pattern (Decatur, IN) has become the preferred pattern provider for local foundries serving the automotive, agriculture, marine, and consumer products industries.

Owner and President Keith Gerber explains the philosophy that guides the business: “We are a pattern shop, but first and foremost we provide service. We used to work in a pattern shop that had a foundry attached to it, so we have that close understanding of how foundries operate and what their needs are. For example, being able to get a job on a Friday afternoon and have it back to the customer Saturday morning. It doesn’t happen a lot, but knowing they can get this kind of response from us, coupled with high quality and competitive prices, are the things that keep our customers coming back to us.”

When changes are required, Hoosier puts the tools in place to facilitate tight collaboration with the customer. “We use web conferencing to show them how we make the changes in our software, and they can react and approve or request additional changes in real-time. Customers are always amazed at how quickly we can make changes in our CAD/CAM. We've done things in minutes that they said would have taken them an hour to do. One customer was so impressed, they purchased a seat of the software for their own use, so we can go back and forth with ideas and changes.”

7. Embrace the Brave New World of Social Media

Industrial Mold & Machine (Twinsburg, OH) is a pioneer in the use of social media technology to enable collaboration. Sales staff, CNC machinists, programmers, and apprentices utilize iPads to access a social network created by IMM. The network, dubbed IMM Connect, contains everything from employee handbooks and MSDS sheets to logout/tagout information and details about each job.

Using this system, any employee working on a project has immediate access to all related job information, which is updated in real-time. Each job has its own page on the network, containing the steps that need to be taken to produce that piece, detail drawings in both 2D and 3D, and programming sheets. Employees use iPads from wherever they are to log into IMM’s social network and view current jobs running on the production floor or prepare for the next job.

While the initial goal of the system was to facilitate intra-company collaboration, it has clearly enhanced IMM’s ability to collaborate with customers as well. Email communication with customers is now linked automatically to the job information on the company’s social network. This information contains any attachments received or sent, including data files and drawings. With information instantly available to every employee working on the job, IMM is able to speed up responsiveness to the customer. “There is less of a chance that something will slip between the cracks or be miscommunicated,” says Larry Housel, Head of IT at Industrial Mold.

This immediate access to information is especially important when things deviate from the plan, for example when delivery of material is delayed or price adjustments are required, as well as when customers initiate a design change. “Customers really appreciate when we proactively communicate to them the status of their job—good news or bad—rather than wait for them to inquire about it,” says Housel. “It gives them peace of mind knowing that someone is managing their project.”

Making the information visual is especially powerful. If a picture is worth a thousand words, a video is worth a million. “Because of the software, we are often able to identify potential issues with the customer’s design early in the process,” adds Housel. “We create a video that shows the moving parts in our CAD/CAM software and share it with the customer. Customers love the ability to visualize their mold in action.”

Collaboration Is Key to Manufacturing’s Future

Gone are the days when one company would control the entire manufacturing process from start to finish. Today’s manufacturing process is more complex and interconnected than ever. The strength of the manufacturing sector in North America will be determined by how well we work together as an ecosystem to produce quality goods in the most efficient manner. Companies that build collaboration into their DNA will be the ones that thrive in this environment.

Curtil/Marland

(661) 294-0030

curtil.com/usa

PTA Corporation

(203) 888-0585

ptacorp.com

Solo Tool & Mold

(519) 944-1705

chris@solotool.com

solotool.com

Nortool Precision Machining and Tool

(574) 262-3400

mmodglin@norcoind.com

norcoind.com

Aluminum Injection Mold Company

(585) 502-6087

aluminuminjectionmold.com

Hoosier Pattern

(260) 724-9430

hoosierpattern.com

Industrial Mold and Machine

(330) 425-7374

wendyw@industrialmold.com

industrialmold.com

Related Content

How to Use Scientific Maintenance for More Accurate Mold and Part Troubleshooting

Discover how adopting scientific maintenance approaches helps improve mold lifespan, minimize failures, and optimize production outcomes.

Read MoreConfronting the Mold Design Talent Drought

Recently, I reposted on LinkedIn the results of an informal survey we conducted, which revealed a shortage of skilled mold designers. It quickly gained a lot of traction. Given the response, I thought I'd summarize the feedback and keep the conversation going.

Read MoreWhat is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreDynamic Tool Corporation – Creating the Team to Move Moldmaking Into the Future

For 40+ years, Dynamic Tool Corp. has offered precision tooling, emphasizing education, mentoring and innovation. The company is committed to excellence, integrity, safety and customer service, as well as inspiring growth and quality in manufacturing.

Read MoreRead Next

Taking Streamlining to the Next Level

Based in Rochester, NY, Aluminum Injection Mold Company (AIM; Rochester, NY) is an industry pioneer in providing creative production aluminum tooling solutions to a wide range of markets including automotive, medical, computer / business machines, telecommunications and consumer products since 1985.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More